Tundish permanent lining preparation method and construction molding bed thereof

A tundish and permanent technology, applied in the field of tundish, can solve the problems of permanent lining damage and low service life of the tundish, and achieve the effects of reducing stress, high service life and good use effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

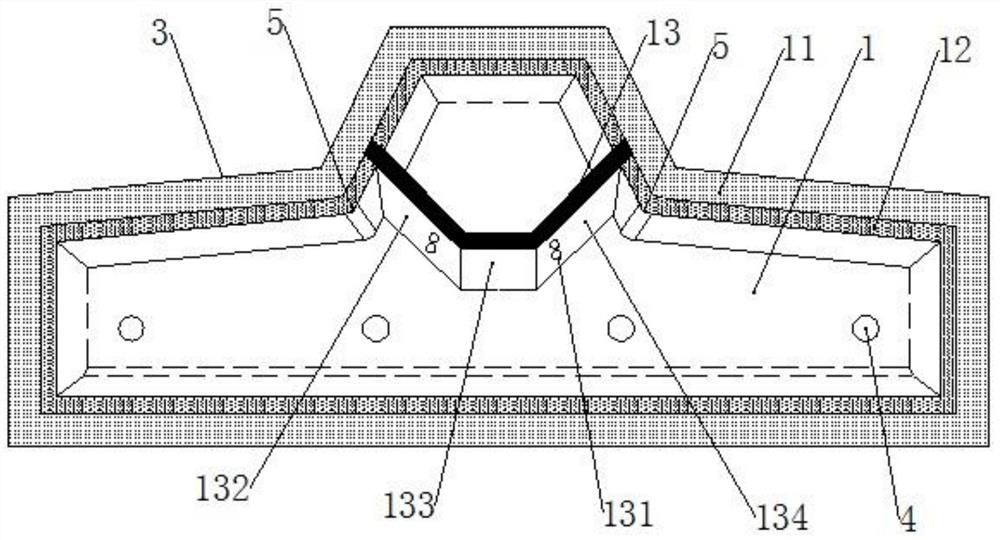

[0055] The present invention also provides a method for preparing a tundish with a permanent lining, the method comprising the following steps:

[0056] Step 1, pouring of permanent liner bottom;

[0057] Place the seat brick on the 4th hole of the nozzle hole, completely cover the 4th hole of the nozzle hole, pour the permanent lining castable to the bottom of the tundish shell 3, and pour it until it is flush with the seat brick. After the bottom pouring material is solidified, the bottom pouring of the permanent liner 11 is completed. Preferably, the standing time is more than 24h.

[0058] Step 2, pouring of permanent lining cladding;

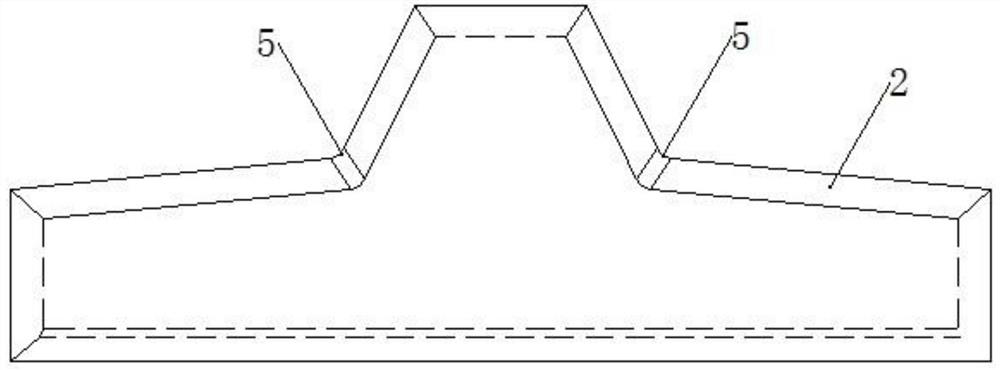

[0059] Apply lubricating oil on the outer wall surface of the construction membrane 2 of the permanent lining, place it in the tundish shell 3, fill the permanent lining castable into the gap between the shell 3 and the construction membrane 2, and make the castable and the cladding 3 After the castable is solidified, the construction fi...

Embodiment 1

[0065] This embodiment provides a method for preparing the permanent lining of the tundish 1, including the tundish shell 3, the construction film 2 of the tundish permanent liner 11, and the construction film 2 has arcs at the corners on both sides of the T-shaped groove The radius of the arc-shaped chamfer is 100mm, and the length of the joint is exactly one-sixth of a circle.

[0066] The construction steps of the permanent lining are as follows: after placing the seat brick in the hole of the seat brick (namely, the nozzle hole 4), start pouring the permanent lining at the bottom of the tundish, pour the pouring material until it is flush with the seat brick, and let it stand for 24 hours after pouring the bottom of the tundish. For more than an hour, hoist the tundish permanent lining construction film 2 coated with lubricating oil into the tundish shell 3 with a crane to keep the gap between the tundish construction film 2 and the shell 3 consistent. Fill the stirred cas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com