Automobile battery liquid cooling plate with three-way joint, and processing technology thereof

A technology for automotive batteries and processing technology, applied in secondary batteries, circuits, electrical components, etc., can solve problems affecting the layout and heat transfer of liquid cold plates, waste of space and cost, and increase the number of inlet and outlet joints, so as to improve heat transfer Efficiency, product cost reduction, and space-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

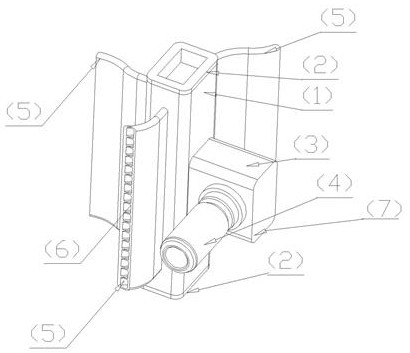

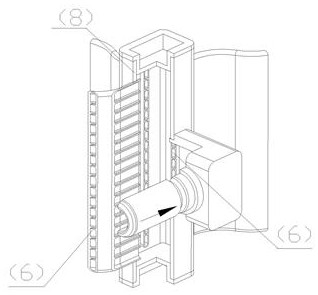

[0020] This embodiment provides a liquid cold plate for automobile batteries with three-way joints, including a collector structure 1, the collector structure 1 is a rectangular parallelepiped high-frequency welded pipe, and the material of the collector structure 1 is the outer layer With a composite layer of aluminum plate, the upper and lower ends of the collector structure 1 are provided with a capping structure 2 through a snap-fitting method. The capping structure 2 is a rectangular aluminum plate stamped and formed part, and the material of the capping structure 2 is A double-sided composite layer aluminum plate is selected, and the sealing cap structure 2 is punched an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com