Grid plate and braided rope combined sealing structure

A sealing structure and grille technology, which is applied in the direction of leakage prevention, engine components, machines/engines, etc., and can solve problems affecting sealing performance and increasing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described in further detail below in conjunction with embodiment.

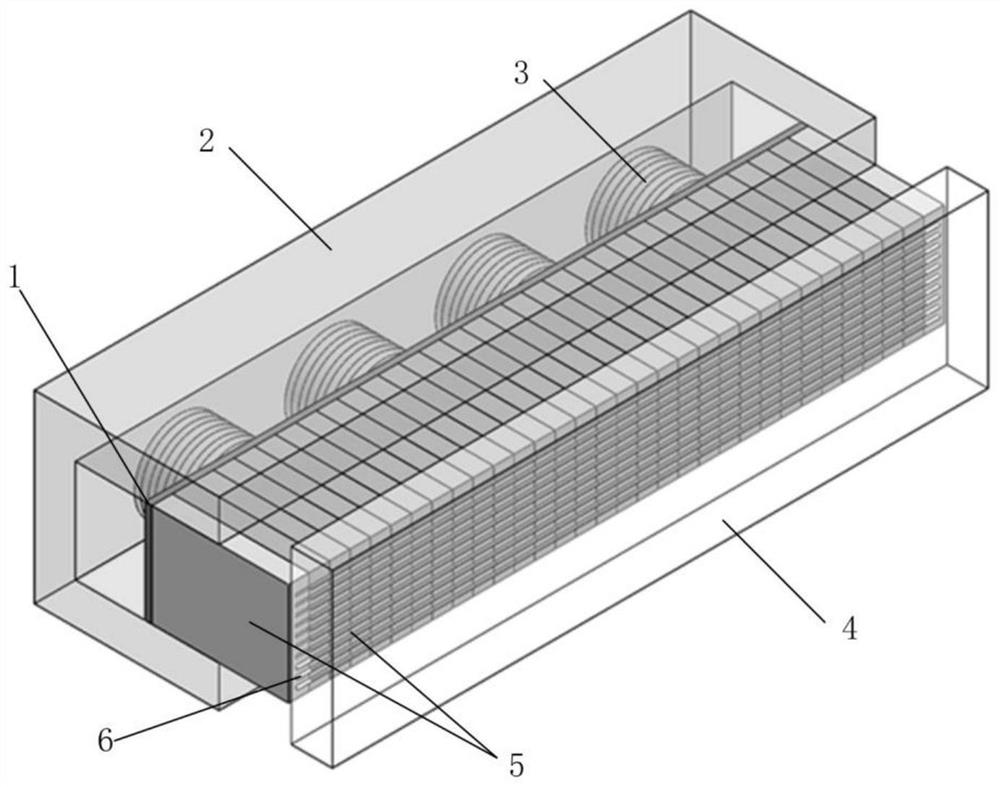

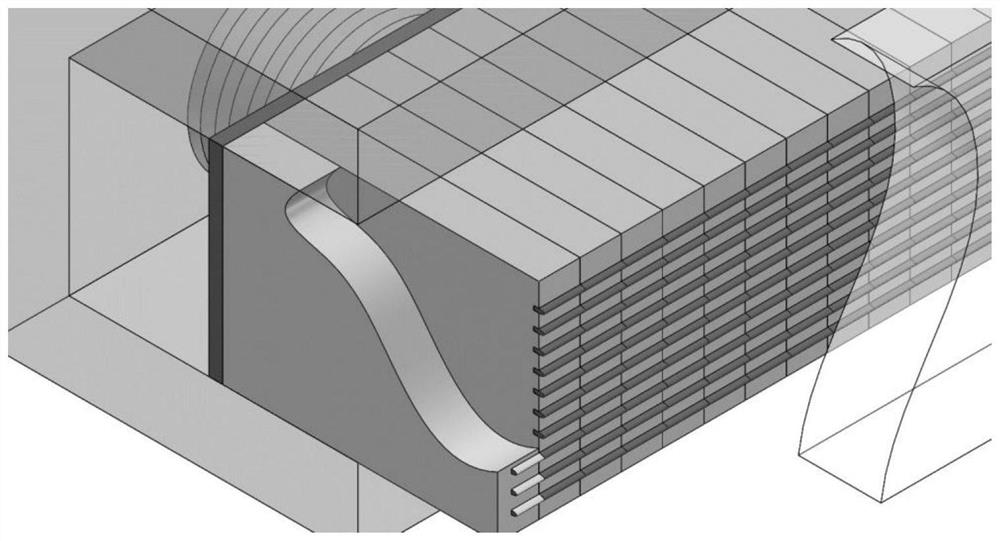

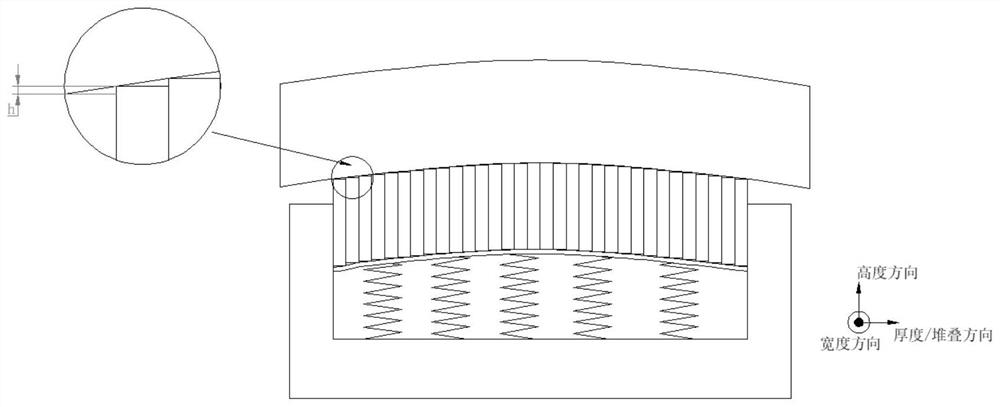

[0028] Such as Figure 1-Figure 4 As shown: the sealing structure is mainly for reducing the gap between the side wall 4 and the grid plate group 5 after thermal deformation. After thermal deformation, the side wall 4 is concave relative to the grid plate set 5 , and an approximately triangular gap is formed between the grid plate set 5 and the side wall 4 . In order to fill the gap, micron-scale grooves are processed at one end of the grid plate group 5 in contact with the side wall 4, and the length of the grooves of the grid plate group 5 at both ends should be less than the thickness of the grid plate group 5, so as to avoid the fiber braided rope 6 from the side wall 4. drop.

[0029] After processing the grooves, micron-scale fiber braided ropes 6 are placed in the grooves in sections (ideally, each groove of each grid plate), and the segmented placement is conducive to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Groove width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com