Hole forming method for ultra-deep large-diameter bored pile

A bored pile and hole-forming technology, which is applied to drilling equipment and methods, directional drilling, earthwork drilling, etc., can solve problems such as low construction efficiency, large vibration interference, and small environmental impact, so as to save materials and reduce costs , the effect of good social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings.

[0039] see Figure 1 to Figure 9 , the described method for forming a hole of an ultra-deep and large-diameter bored pile is characterized in that it comprises the following steps:

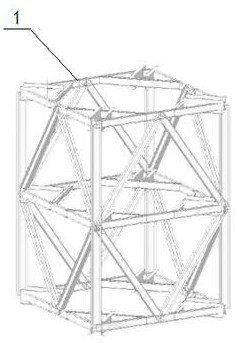

[0040] The first step is to make the casing guide frame;

[0041] Casing guide frame 1 adopts a double-layer frame structure, and the connecting system, column, and guide support of the casing guide frame 1 are made of double 20a, 25a, 40a channel steel respectively;

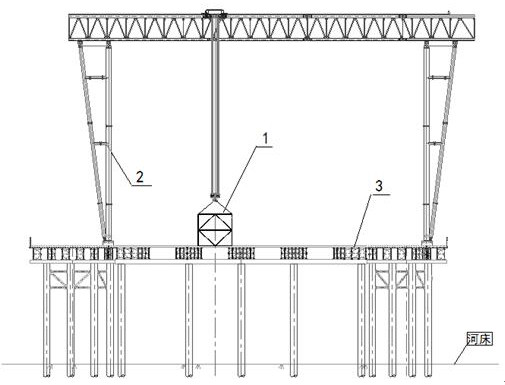

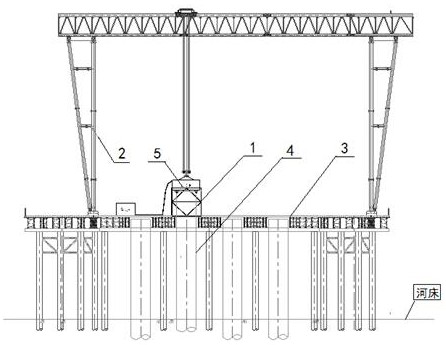

[0042] The second step is the positioning of the casing guide frame;

[0043] Said casing guide frame 1 utilizes 60t gantry crane 2 to hoist to positioning on the drilling platform 3;

[0044] The third step is to insert the steel casing;

[0045] Firstly, 16mm steel plate is rolled in the field to make a 8m section of steel casing, and then the steel casing 4 is transported to the drilling platform 3 by a flatbed truck ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com