Rapid construction method of reinforced concrete chimney

A technology of reinforced concrete and construction methods, applied in building types, buildings, towers, etc., can solve the problems of reduced labor productivity, hidden dangers in electricity safety, and increased unsafe factors, so as to save formwork construction operations and avoid high-altitude suspension. work and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

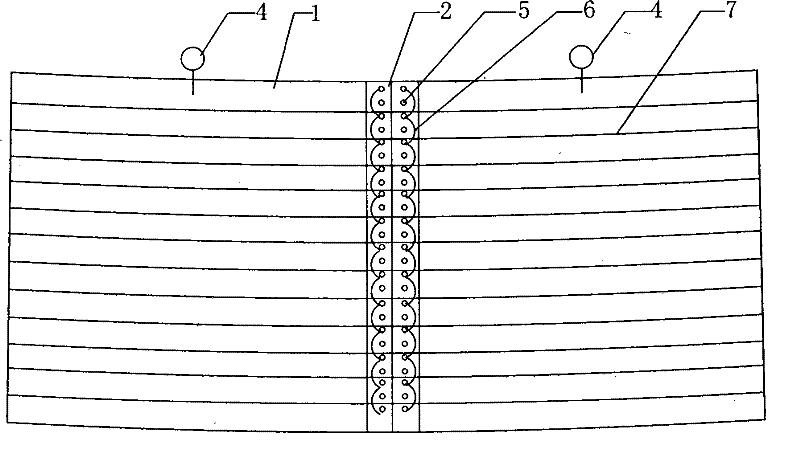

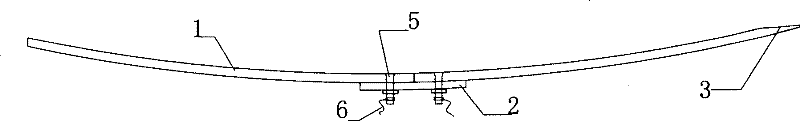

[0039] Such as figure 1 As shown, the formwork of the present invention is formed by splicing and fixing two steel plates 1 with a thickness of 2 mm through strip-shaped connecting steel plates 2. The steel plates 1 and the connecting steel plates 2 are anchored by flat-head screws 5 from the inside to the outside. The steel plates 1 There are many fastening wire ropes 7 fixed in the horizontal winding of the outside, and the anti-off steel wire 6 that prevents the fastening wire rope 7 from slipping is fixed on the flat head screw 5 outside. One side of each group of templates has a narrowing edge 3, the thickness of the narrowing edge 3 is 1mm, and the width is 20mm. The outer side of the connecting steel plate 2 is welded with a formwork lifting hook 4, and the surface of the formwork is coated with a concrete release agent.

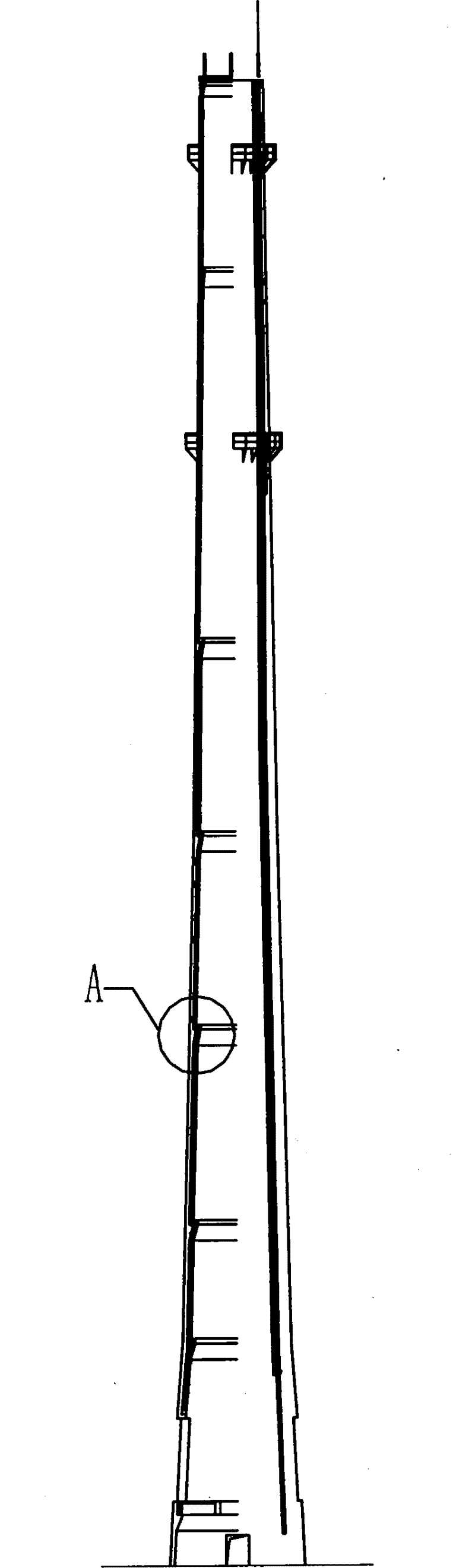

[0040] Such as figure 2 and image 3 As shown, the chimney structure of the present invention includes a reinforced concrete layer 8, a heat insu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com