BIM (Building Information Modeling)-based super-high-rise super-thick mass concrete one-time pouring construction method in hot weather

A technology of mass concrete and construction method, applied in geometric CAD, computer-aided design, design optimization/simulation, etc., can solve problems such as difficulty in optimizing on-site construction, difficult control of construction quality, and large volume of one-time pouring. , to achieve the effect of optimizing construction organization, easy temperature control, and reducing cold joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

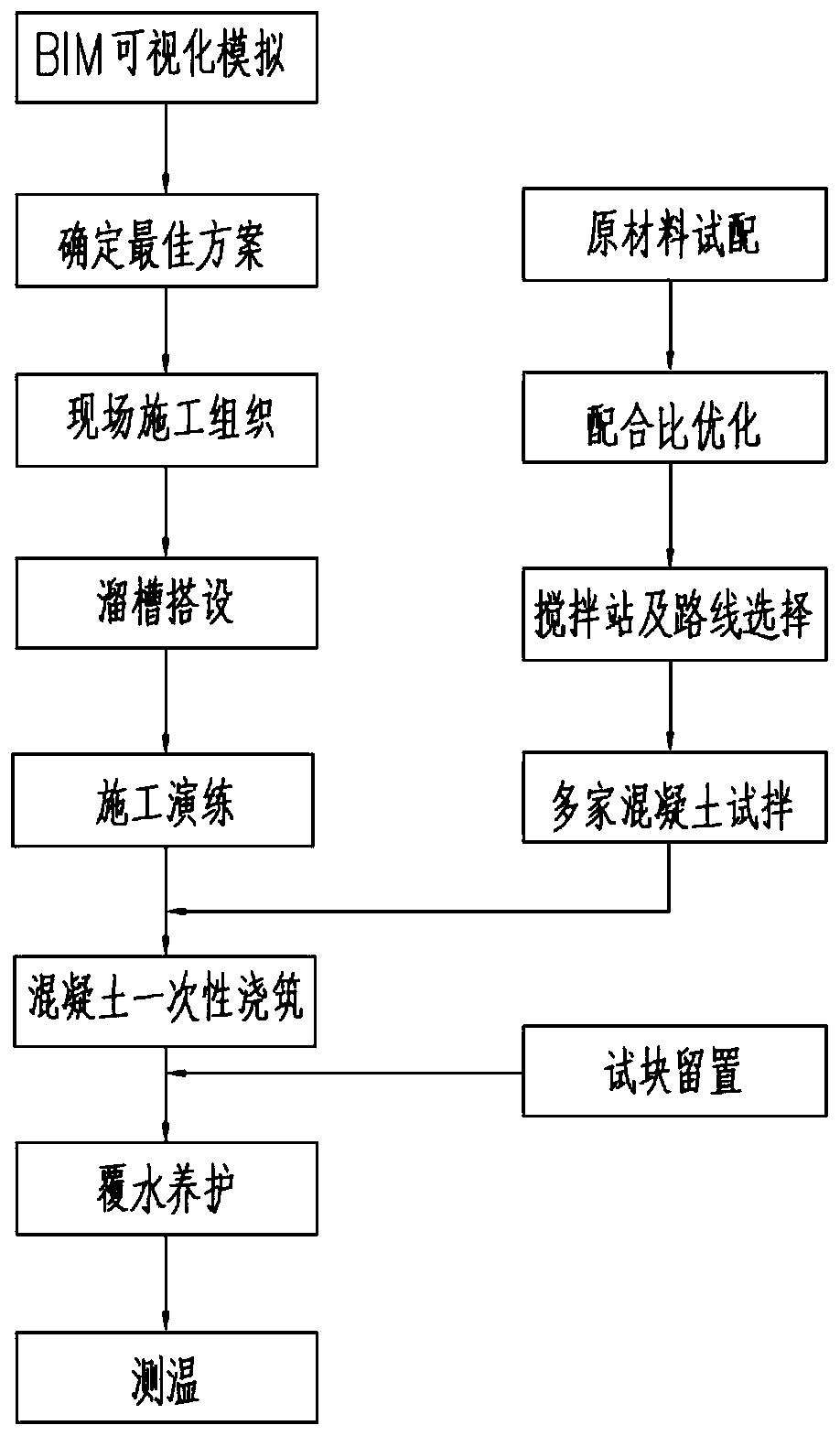

[0069] A BIM-based one-time pouring construction method for super-high-rise ultra-thick and large-volume concrete in hot climates. Optimize the scheme, optimize the unreasonable and uneconomical parts, in order to achieve the best construction effect;

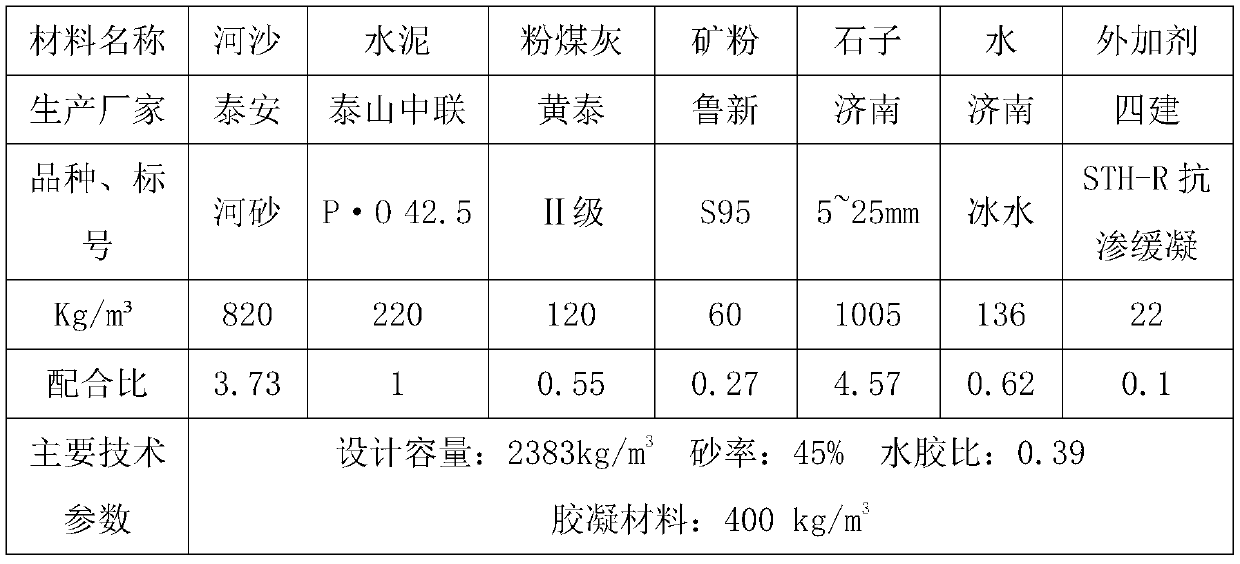

[0070] By optimizing the concrete mix ratio, reducing the amount of cement and increasing the amount of fly ash, the generated heat of hydration is reduced, the temperature is easy to control, and the occurrence of temperature cracks is reduced;

[0071] The chute method is used for one-time pouring, the construction speed is fast, and the construction period and project cost are greatly saved;

[0072] Optimize the construction organization, ensure the continuous supply of concrete during the construction process, and reduce the generation of cold joints;

[0073] The water-covering method is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com