Construction method of large-diameter steel pipe column ring beam and operation platform

A construction method and operating platform technology, applied in the direction of pillars, scaffolding accessories, building materials processing, etc., can solve the problems that cannot meet the actual production requirements on site, low work efficiency, and difficult quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0025] Embodiments of the invention: see figure 1 and figure 2 , a construction method of a large-diameter steel pipe column ring beam of the present invention, comprising the following steps:

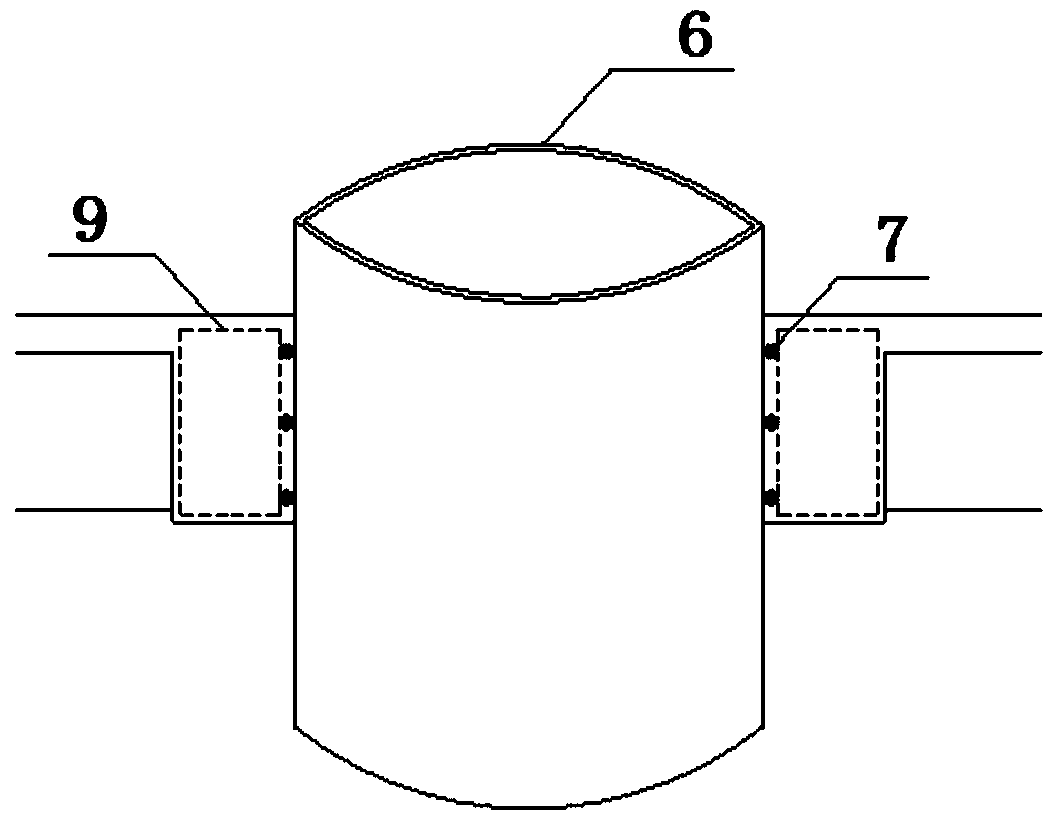

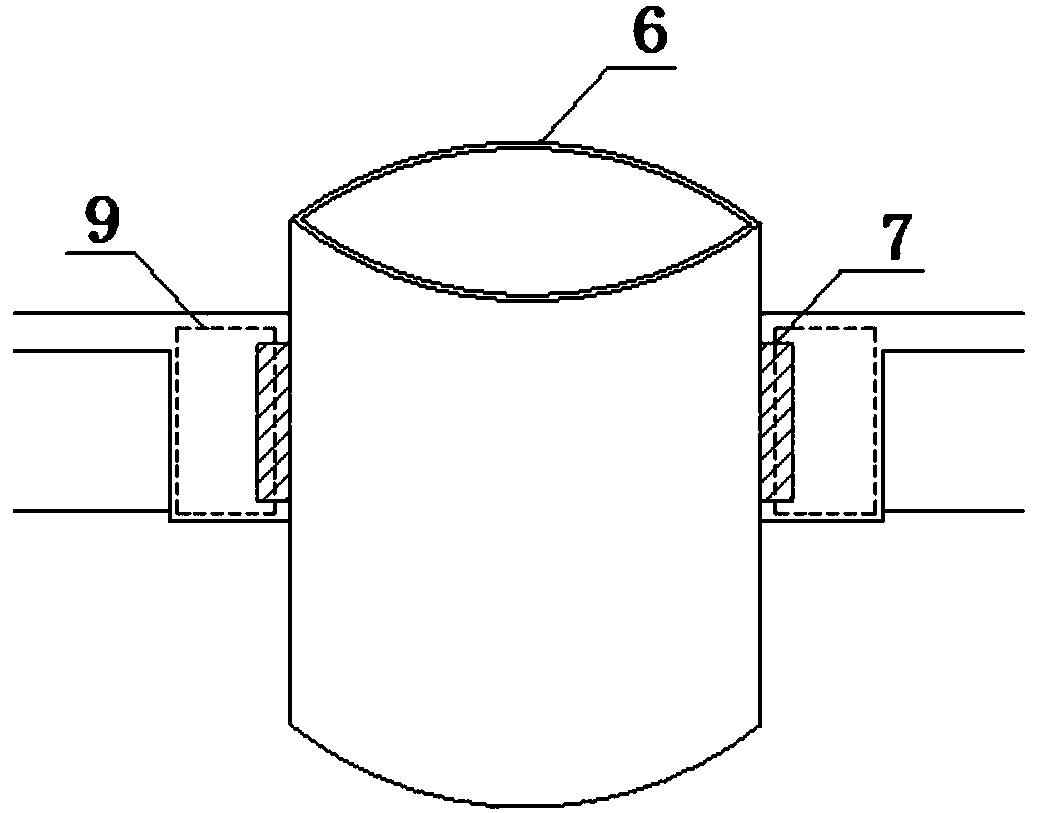

[0026] Step 1. Separation and optimization of the beam-column shear joints for the steel pipe column 6 and the ring beam, that is, the construction is carried out in the form of a shear reinforcement ring node, so that the outer facade of the steel pipe column 6 and the steel bars inside the ring beam reinforcement cage 9 do not intersect , forming a construction form in which the ring beam reinforcement cage can be tied independently;

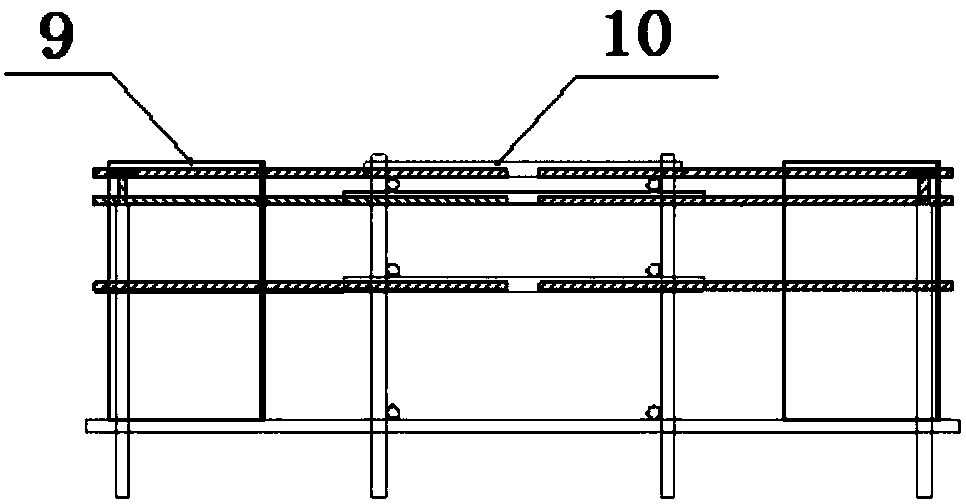

[0027] Step 2, setting up the operating platform 10 for ring beam reinforcement binding;

[0028] Step 3, centralize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com