Degradable plant-based lubricating oil and preparation method thereof

A lubricating oil, plant-based technology, applied in the field of lubricating oil, can solve problems such as weak oxidation stability, achieve good low temperature performance, good synergistic antibacterial property, and good antibacterial effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

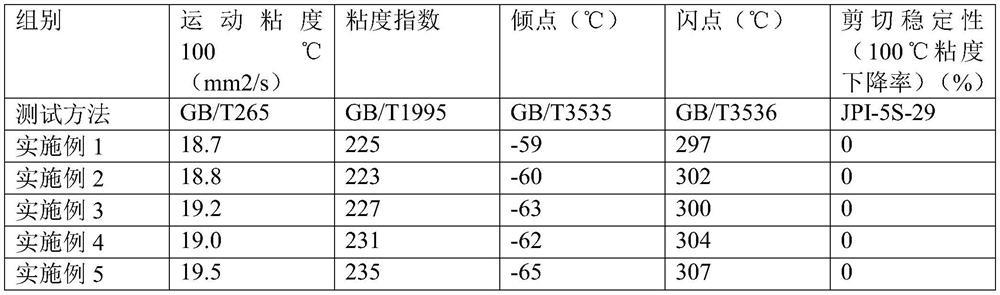

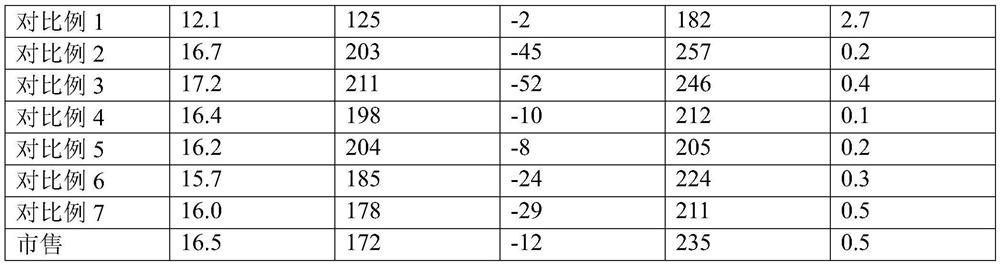

Examples

Embodiment 1

[0039] Embodiment 1 degradable plant-based lubricating oil

[0040] Composition of raw materials (parts by weight): 50 parts of modified peanut oil, 1 part of tartaric acid, 2 parts of graphite nano powder, 1 part of calcium aluminate powder, 1 part of high-efficiency antioxidant, 2 parts of stearic acid, 1 part of arachidic acid, antibacterial synergy 0.5 part of agent, 20010 parts of polyethylene glycol, 1 part of polyoxyethylene polyoxypropylene pentaerythritol ether.

[0041] The antibacterial synergist is a mixture of nisin and chitin with a mass ratio of 1:1.

[0042] Modified peanut oil is prepared by the following methods:

[0043] S1. Transesterification of peanut oil: 100 g of peanut oil and 100 g of n-butanol were heated to reflux under the catalysis of 10 mL of concentrated sulfuric acid with a mass percentage concentration of 98% or more, reacted for 2 hours, cooled, washed with water, and distilled to obtain peanut oil alkyl ester;

[0044] S2. Preparation of e...

Embodiment 2

[0051] Embodiment 2 degradable plant-based lubricating oil

[0052] Composition of raw materials (parts by weight): 100 parts of modified soybean oil, 3 parts of potassium diethylenetriaminepentaacetate, 10 parts of graphite nano powder, 5 parts of calcium aluminate powder, 4 parts of high-efficiency antioxidant, 7 parts of stearic acid 5 parts, 5 parts of arachidic acid, 1 part of antibacterial synergist, 20020 parts of polyethylene glycol, 2 parts of polyoxypropylene glyceryl ether.

[0053] The antibacterial synergist is a mixture of nisin and chitin with a mass ratio of 1:3.

[0054] Modified soybean oil is prepared by the following methods:

[0055] S1. Transesterification of soybean oil: 100g soybean oil and 100g n-propanol are heated to reflux under the catalysis of 10mL concentrated sulfuric acid with a mass percentage concentration of 98% or more, reacted for 4h, cooled, washed with water, and distilled to obtain soybean oil alkyl ester ;

[0056] S2. Preparation o...

Embodiment 3

[0063] Embodiment 3 degradable plant-based lubricating oil

[0064] Composition of raw materials (parts by weight): 70 parts of modified cottonseed oil, 1.5 parts of diethylenetriaminepentaacetic acid, 4 parts of graphite nano powder, 2 parts of calcium aluminate powder, 3 parts of high-efficiency antioxidant, 3 parts of stearic acid , 2 parts of arachidic acid, 0.6 part of antibacterial synergist, 40012 parts of polyethylene glycol, and 1.2 parts of emulsified silicone oil.

[0065] The antibacterial synergist is a mixture of nisin and chitin with a mass ratio of 1:2.

[0066] Modified cottonseed oil is prepared by:

[0067] S1. Transesterification of cottonseed oil: 100g cottonseed oil and 100g isobutanol are heated to reflux under the catalysis of 10mL concentrated sulfuric acid with a mass percentage concentration of 98% or more, reacted for 3h, cooled, washed with water, and distilled to obtain cottonseed oil alkyl ester ;

[0068] S2. Preparation of epoxidized cottons...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com