Preparation process of grounded bed sheet

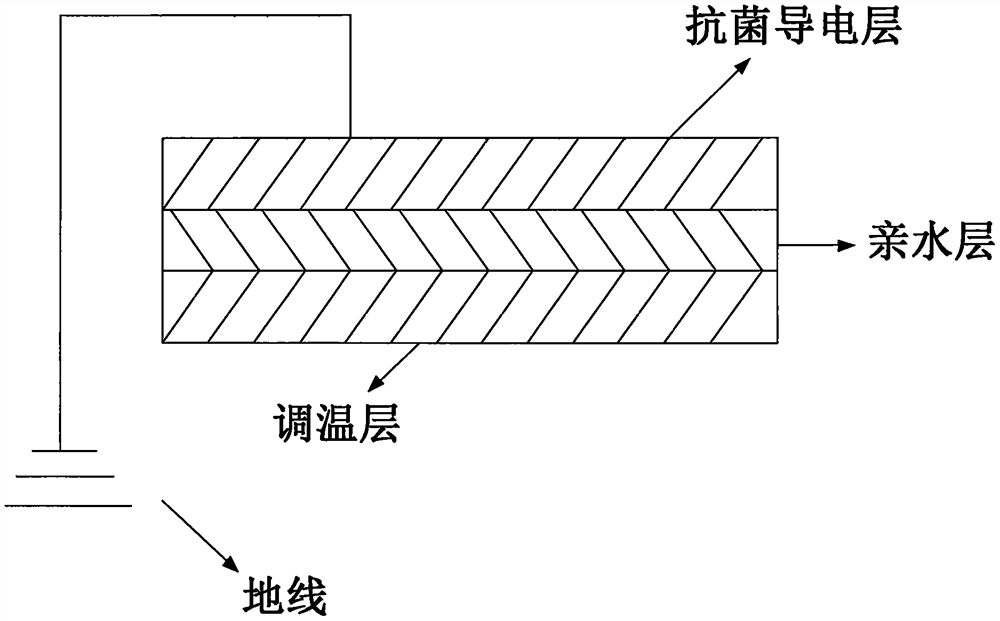

A bed sheet and earth gas technology, applied in bed sheets, textiles, fabrics, etc., can solve the problems of single anti-static method and single function, achieve good anti-static ability, and ensure the effect of anti-static function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Add 50g of PCM microcapsules into 10wt% JFC aqueous solution, then mix with 10wt% aqueous solution, stir magnetically at 200rpm at room temperature for 1h, wait until the stirring is completed, and use a spatula to evenly process the coating onto the cotton fabric , and then dried at a temperature of 60° C., and baked at a temperature of 120° C. for 3 minutes to obtain a temperature-regulating layer.

[0035] (2) Fully mix 2wt% tetraethyl silicate and 2wt% tetrabutyl titanate with 100ml of ethanol, add 1wt% acetic acid dropwise at a slow speed under the stirring condition of 600rpm, and react at room temperature for 8h , making SiO 2 / TiO 2 Composite hydrosol, the cotton fabric is treated with two dipping and two rolling processes, with a liquid concentration of 130%, dried at 80°C, and baked at 140°C for 3 minutes to obtain a hydrophilic layer.

[0036] (3) The silver-plated fiber is used as the warp yarn, the cotton fiber is used as the weft yarn, and the yarn-t...

Embodiment 2

[0039] (1) Add 80g of PCM microcapsules into 10wt% JFC aqueous solution, then mix with 10wt% aqueous solution, stir magnetically at 200rpm at room temperature for 1h, wait until the stirring is completed, and evenly process the coating onto the cotton fabric with a scraper , and then dried at a temperature of 60° C., and baked at a temperature of 120° C. for 3 minutes to obtain a temperature-regulating layer.

[0040] (2) Fully mix 2wt% tetraethyl silicate and 2wt% tetrabutyl titanate with 100ml of ethanol, add 1wt% acetic acid dropwise at a slow speed under the stirring condition of 600rpm, and react at room temperature for 8h , making SiO 2 / TiO 2 Composite hydrosol, the cotton fabric is treated with two dipping and two rolling processes, with a liquid concentration of 130%, dried at 80°C, and baked at 140°C for 3 minutes to obtain a hydrophilic layer.

[0041] (3) The silver-plated fiber is used as the warp yarn, the cotton fiber is used as the weft yarn, and the yarn-to-...

Embodiment 3

[0044] (1) Add 100g of PCM microcapsules into 10wt% JFC aqueous solution, mix with 10wt% aqueous solution, and stir magnetically at 200rpm for 1h at room temperature. After the stirring is completed, use a scraper to evenly process the coating onto the cotton fabric , and then dried at a temperature of 60° C., and baked at a temperature of 120° C. for 3 minutes to obtain a temperature-regulating layer.

[0045] (2) Fully mix 2wt% tetraethyl silicate and 2wt% tetrabutyl titanate with 100ml of ethanol, add 1wt% acetic acid dropwise at a slow speed under the stirring condition of 600rpm, and react at room temperature for 8h , making SiO 2 / TiO 2 Composite hydrosol, the cotton fabric is treated with two dipping and two rolling processes, with a liquid concentration of 130%, dried at 80°C, and baked at 140°C for 3 minutes to obtain a hydrophilic layer.

[0046] (3) The silver-plated fiber is used as the warp yarn, the cotton fiber is used as the weft yarn, and the yarn-to-weft ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com