Explosion-proof battery

A battery and battery module technology, applied in secondary batteries, battery temperature control, battery pack components, etc., can solve the limitations of the use of lead-acid batteries, restrict the research and development and application of underground robot equipment, and the power supply of large-capacity batteries in the well is not particularly good. solutions to avoid the risk of deflagration, reduce the cost and weight of implementation, improve economy and the effect of explosion-proof control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention. On the contrary, the embodiments of the present invention include all changes, modifications and equivalents coming within the spirit and scope of the appended claims.

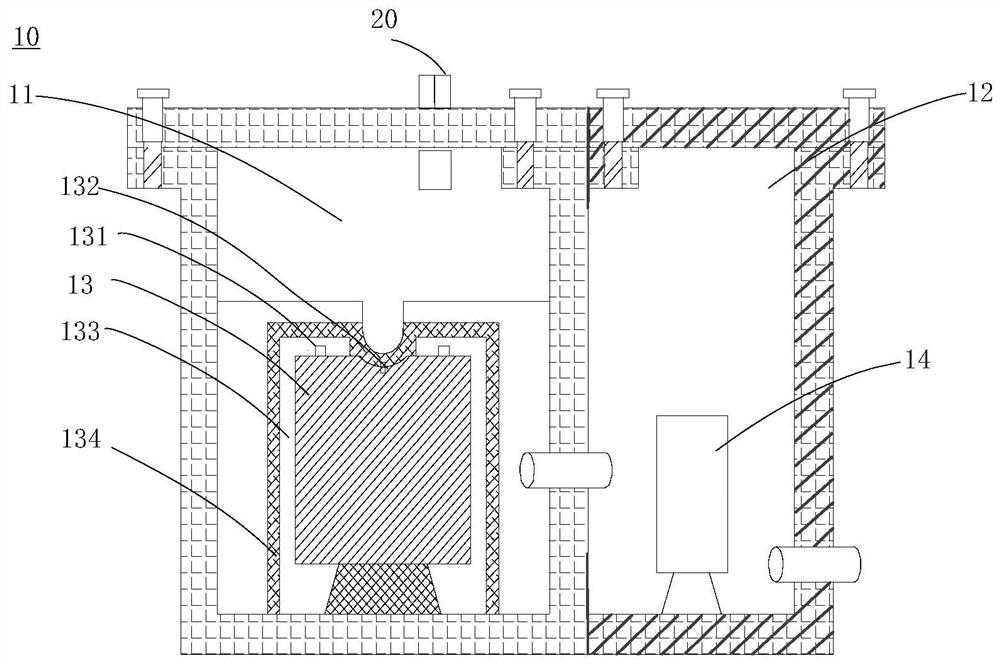

[0014] figure 1 It is a structural schematic diagram of an explosion-proof battery proposed by an embodiment of the present invention.

[0015] see figure 1 , the explosion-proof battery 10 includes: a box 11 and an explosion-proof box 12 connected to the box 11; a temperature adjustment module 20 connected to the box 11, and the temperature adjustment module 20 is used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com