Photolithography method

A lithography and strip technology, applied in the field of lithography, can solve the problems of cumbersome process steps, high cost, unstable influence of overlay accuracy on lithography resolution, etc., and achieve enhanced resolution and enhanced lithography resolution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

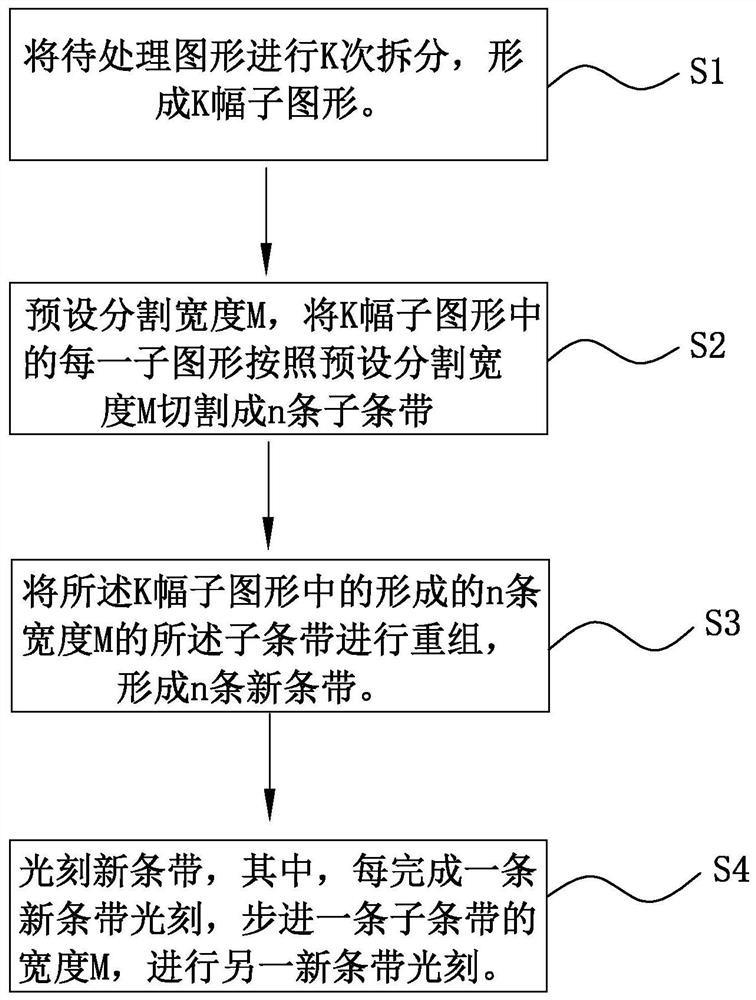

[0030] Please refer to figure 1 , the photolithography method provided in the embodiment of the present invention, the photolithography used for the pattern to be processed includes a photolithography machine with a moving platform, and a preset scanning mode, and the method includes the following steps.

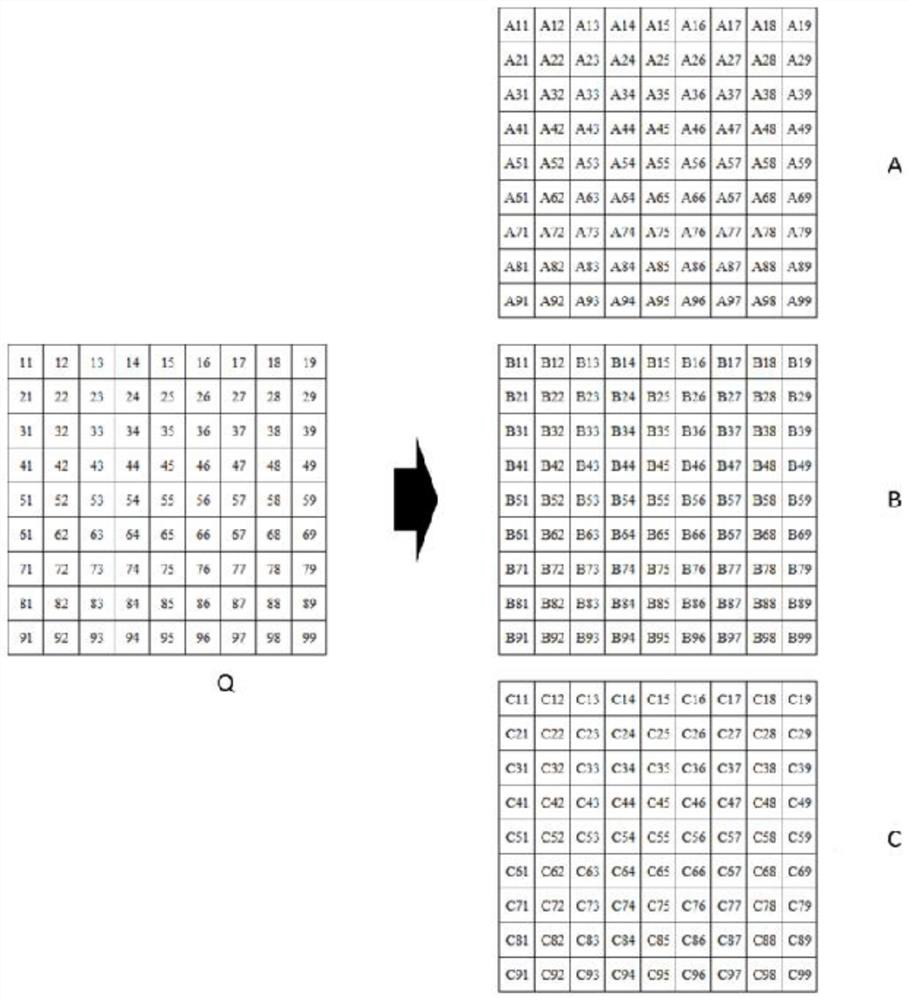

[0031] S1: split the graph to be processed K times to form K sub-graphs;

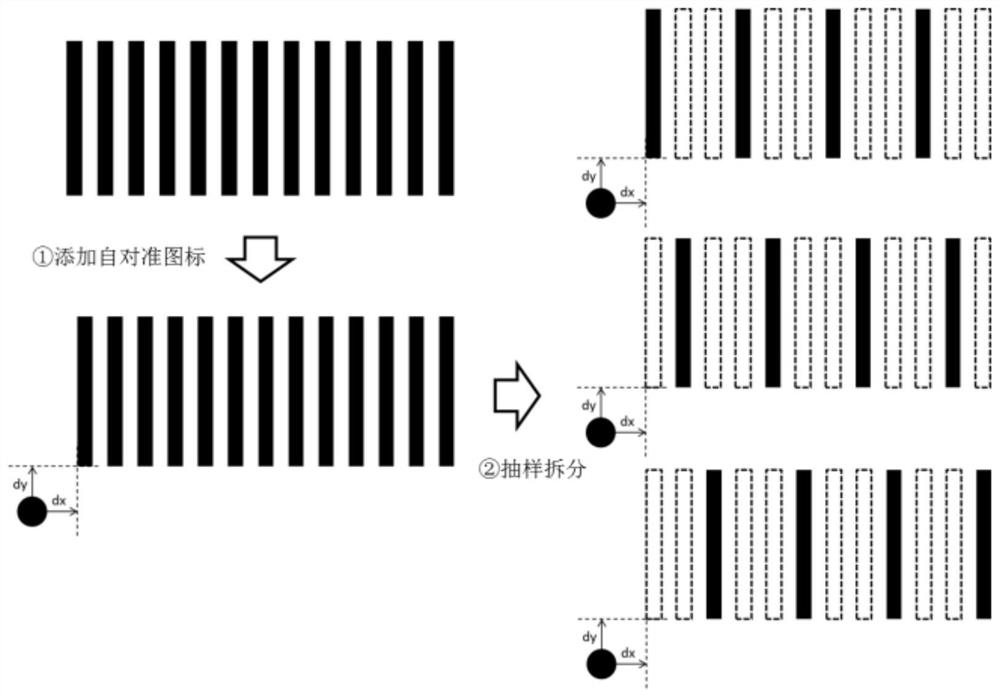

[0032] Specifically, before splitting, a splitting method and a mark alignment icon are preset. Divide the graph to be processed into K sparse sub-graphs; after splitting, each sub-graph has an alignment icon of the dense graph to be processed. Wherein, the preset splitting method includes regu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com