Electrical engineer electrical appliance connection detection workbench

A technology for testing workbenches and electrical connections. It is applied in the direction of manufacturing tools, welding equipment, welding equipment, etc., and can solve problems that affect accuracy, the pins of the original parts are difficult to eat tin, and the pins are damaged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

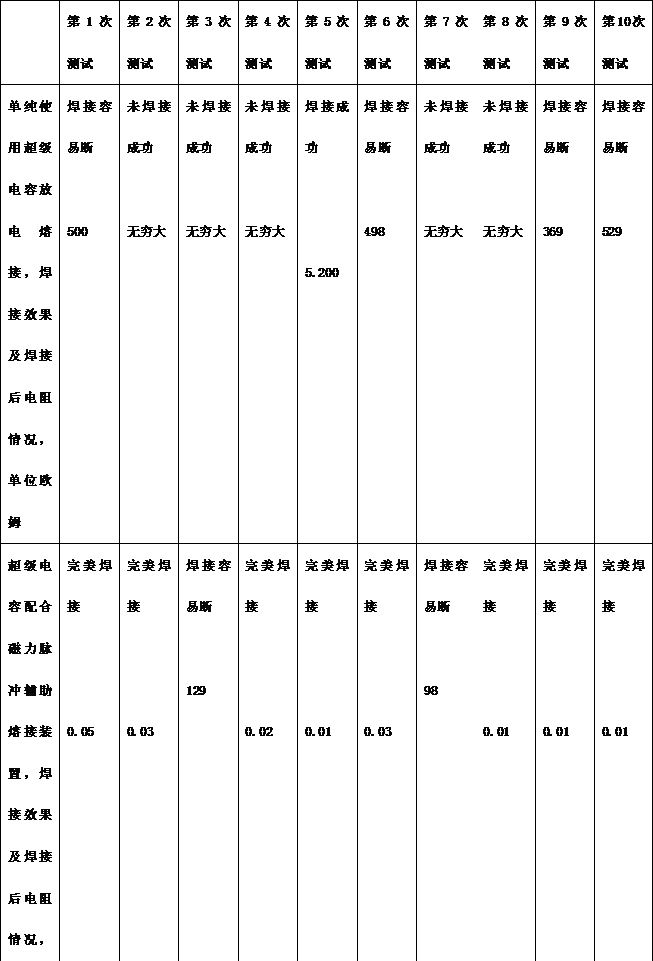

[0018] The present invention adds a magnetic pulse auxiliary welding device on the basis of the workbench. The magnetic pulse auxiliary welding device utilizes the characteristic that the supercapacitor 1 can generate a large current discharge. pins, so that a large current flows through the contact area of the two pins, and the contact area of the two pins is heated by high temperature. In most cases, after the welding is completed, the two pins will be disconnected with a slight external force, and the contact resistance will still not decrease. Through further research, we found that after applying a pulsed magnetic field to the first conductive fixed rod 3 and the second conductive fixed rod 4, the success rate of welding the two pins can be greatly improved, and the contact resistance of the two pins can be greatly reduced. The specific method Yes: the first conductive fixed rod 3 is covered with a first ferrite tube 8, the outer side of the first ferrite tube 8 is ...

Embodiment 2

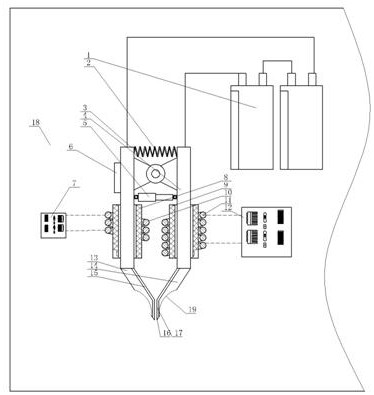

[0026] An electrical engineer's electrical connection testing workbench, such as Figure 1-Figure 2As shown, including platform board 18, first pulse generator 7 and second pulse generator 12, the top of platform board 18 is equipped with magnetic force pulse assisted welding device, and described magnetic force pulse assisted welding device comprises fixed support 6, and the fixed support 6 The upper part is connected with the first conductive fixed rod 3, the second conductive fixed rod 4 is installed on one side of the first conductive fixed rod 3, the middle part of the first conductive fixed rod 3 and the middle part of the second conductive fixed rod 4 are hinged, and the first conductive fixed rod 3 is covered with a first ferrite tube 8, the outer side of the first ferrite tube 8 is covered with a first coil 10, and the two output terminals of the first pulse generator 7 are respectively connected to both ends of the first coil 10 connection, the second conductive fixi...

Embodiment 3

[0028] An electrical engineer electrical connection testing workbench such as Figure 1-Figure 2 As shown, including platform board 18, first pulse generator 7 and second pulse generator 12, the top of platform board 18 is equipped with magnetic force pulse assisted welding device, and described magnetic force pulse assisted welding device comprises fixed support 6, and the fixed support 6 The upper part is connected with the first conductive fixed rod 3, the second conductive fixed rod 4 is installed on one side of the first conductive fixed rod 3, the middle part of the first conductive fixed rod 3 and the middle part of the second conductive fixed rod 4 are hinged, and the first conductive fixed rod 3 is covered with a first ferrite tube 8, the outer side of the first ferrite tube 8 is covered with a first coil 10, and the two output terminals of the first pulse generator 7 are respectively connected to both ends of the first coil 10 connection, the second conductive fixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com