Piezoelectric acceleration sensor capable of detecting working state in real time and detection method

A technology of acceleration sensor and working state, applied in the field of sensor measurement, which can solve the problems of loose installation, deviation of output signal, and change of high-frequency characteristics of sensor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

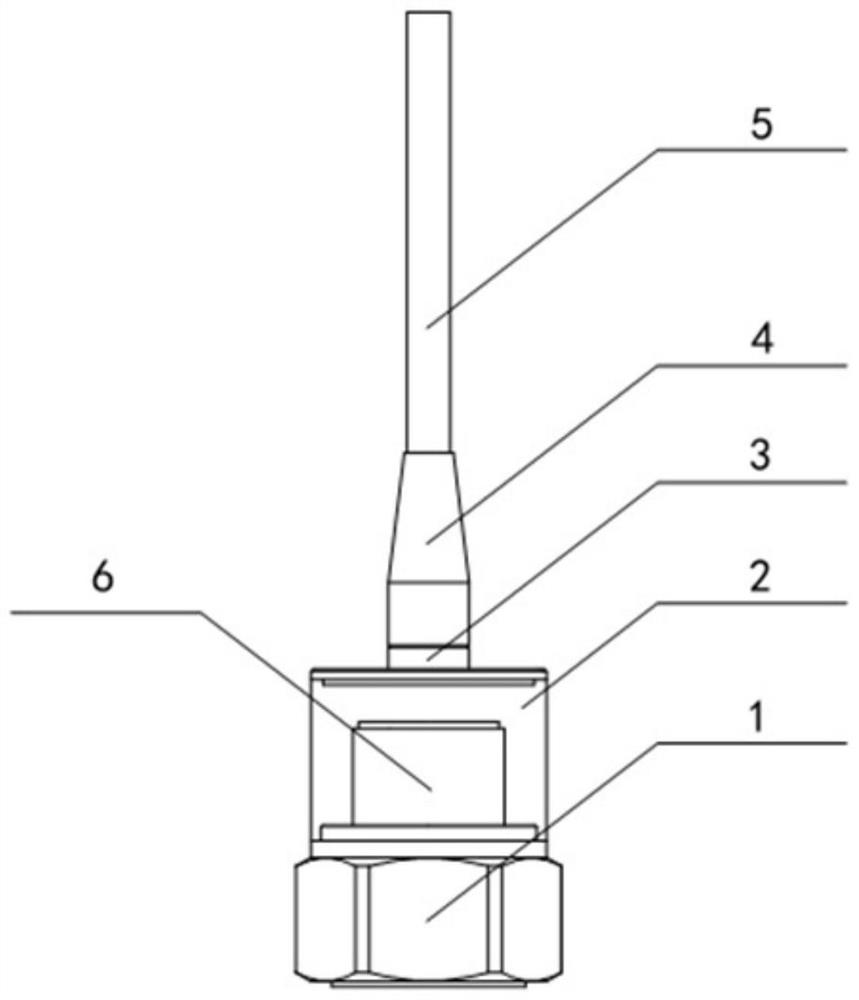

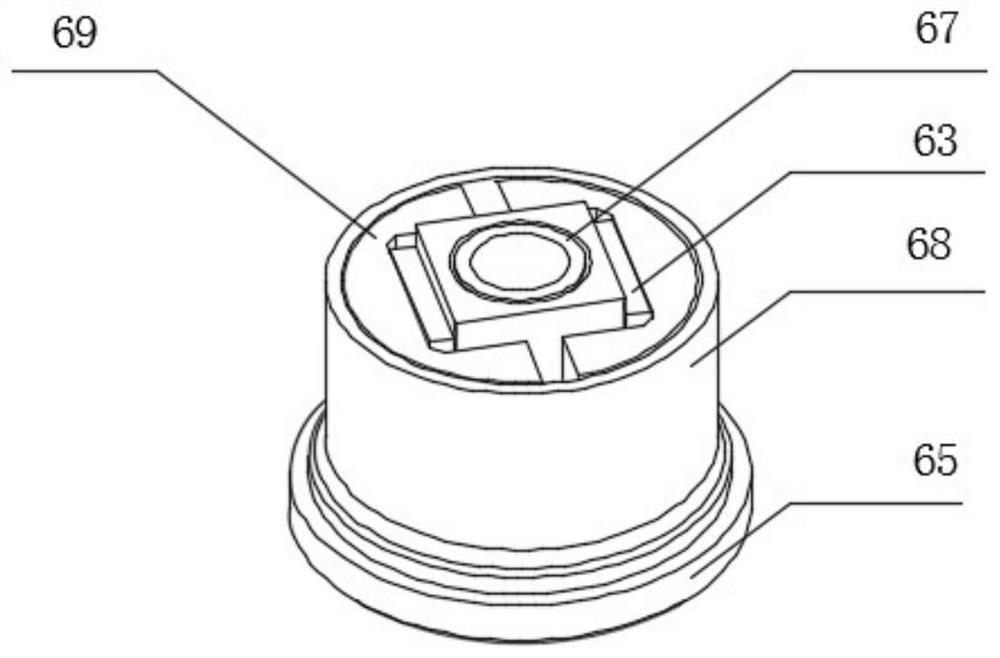

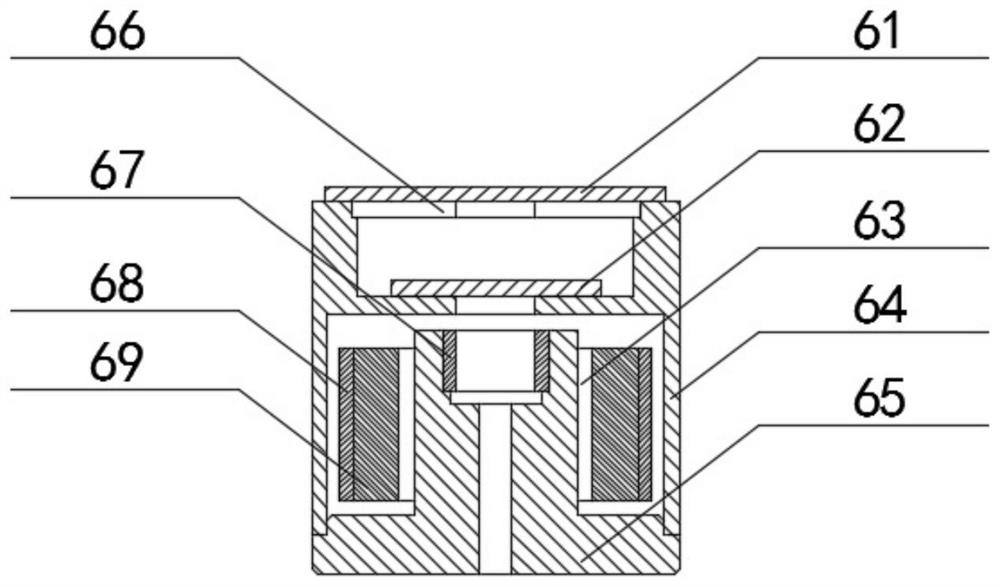

[0019] Such as Figure 1-2 As shown, the piezoelectric acceleration sensor capable of real-time detection of the working state of the present invention includes a base 1, a housing 2 is fixed on the base, a sensor core 6 is fixed inside the housing, and a wire is arranged on the housing. Cable connector 3, the cable connector is connected to the signal output cable 5, the cable connector is provided with a cable sheath 4; the sensor core includes a core base 65 with a square base in the middle of the core base A column, the two sides of the square base column are respectively provided with a plane shear type signal acquisition piezoelectric ceramic 63, each of the signal acquisition piezoelectric ceramics is covered with a mass block 69, and the mass block is externally passed through a preloaded The ring 68 is fixed, and holes are punched on the column of the square base and the ring shear type excitation piezoelectric ceramic 67 is fixed with conductive glue. The core base i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com