Forced air drying device and method for removing residual electrolyte by adopting forced air drying device

A technology of blast drying and blasting device, which is applied in the direction of drying gas arrangement, drying chamber/container, non-progressive dryer, etc. The pipeline design line is simple, the equipment cost is saved, and the drying efficiency is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings. The following will be described in conjunction with the cylindrical lithium-ion battery cell 12 as an example.

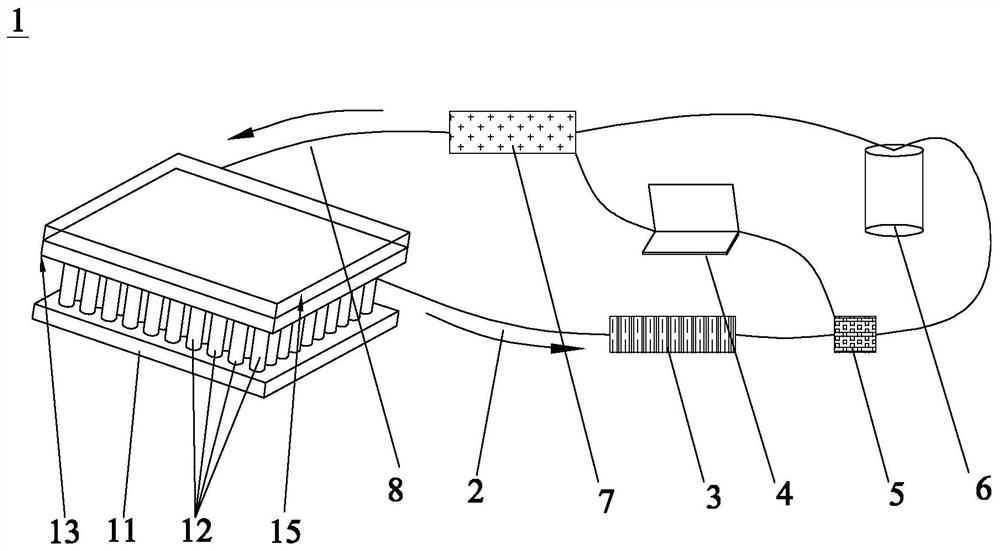

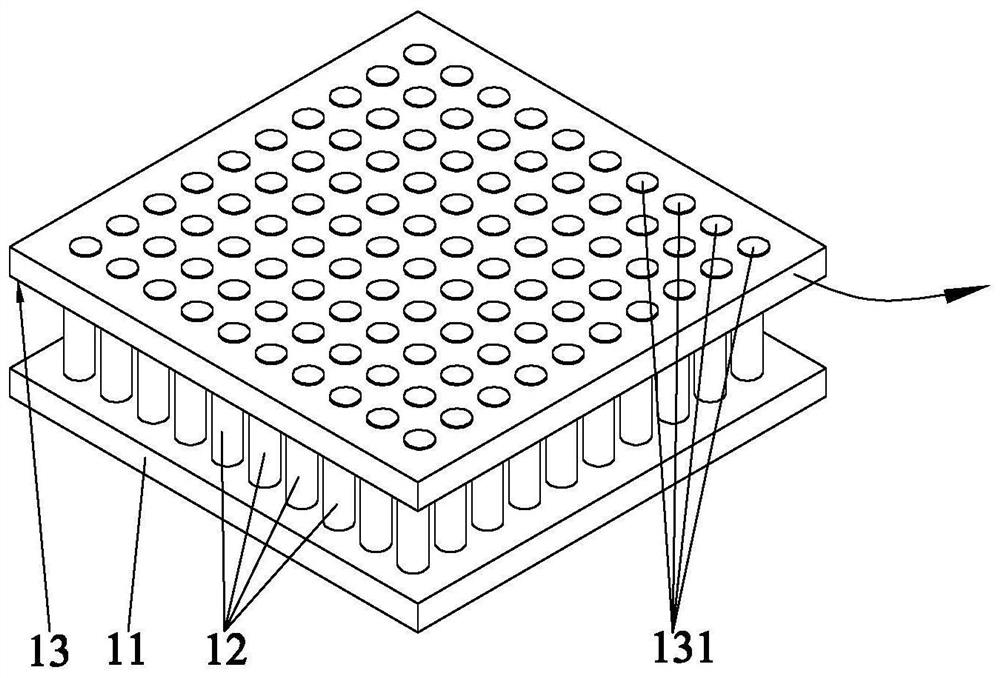

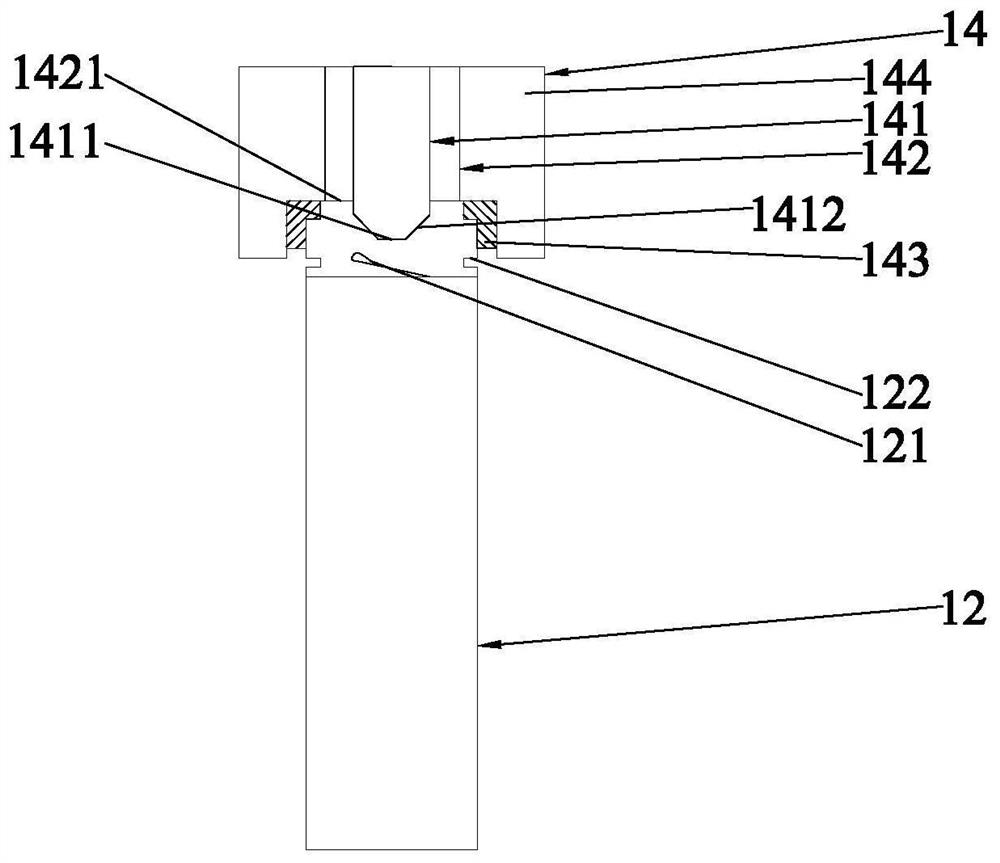

[0032] to combine Figure 1-Figure 4 , the blast drying device 1 of the present invention is used to remove the electrolyte at the shell mouth 122 of the battery cell 12, including a cell tray 11 for carrying the battery cell 12, a blast drying tray 13, a pressurized blast device 15, Dryer 3 , computer monitoring system 4 , gas component content monitoring device 5 , gas storage tank 6 and gas monitoring device 7 . The blast drying tray 13 is positioned with a blast drying unit 14 matching the electric core 12, and the air inlet pipe 141 of the blast drying unit 14 is matched with the pressurized air blowing device 15 and communicated with the air intak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com