Pressure pipeline connecting and sealing device for conveying fluid

A technology for pressure pipelines and fluid delivery, which is applied in the direction of sleeve/socket connections, pipes/pipe joints/fittings, passing components, etc. It can solve the problems of affecting the diameter of the pipeline, low pressure resistance, leakage of the sealing position, etc., and achieve no damage The effect of compressive strength, convenient installation and connection, and convenient replacement and sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

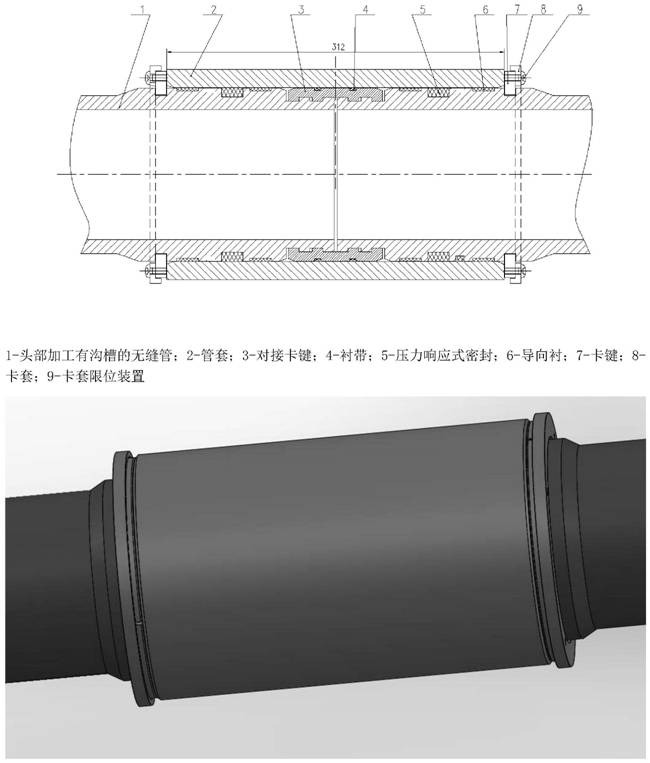

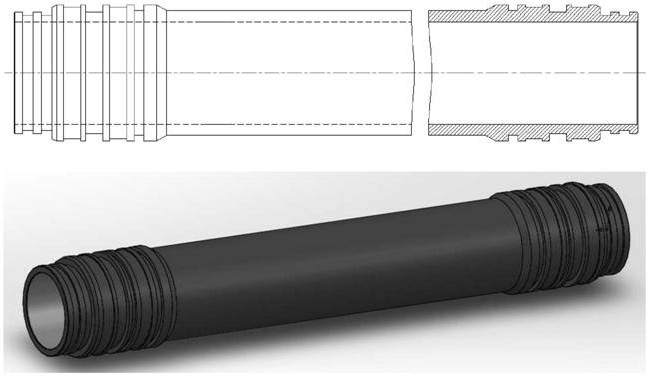

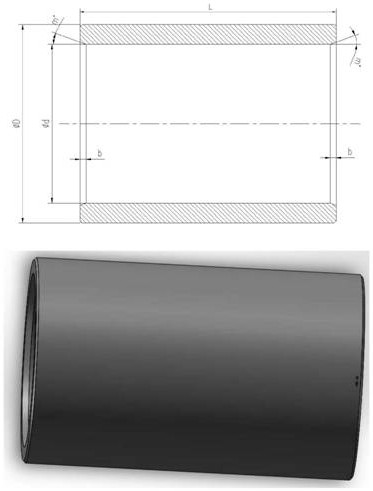

[0017] The invention provides a fluid pipeline connection method, with reference to figure 1 In this embodiment, a docking key (3) is used to connect two seamless pipes (1) with grooves on their heads to restrict the left and right movement of the two pipes. A pipe sleeve (2) is used to restrict the movement of the front and back up and down positions of the two seamless pipes (1) with grooves on the heads and the butting key (3). The seamless pipe with grooves on the head (1) is equipped with a pressure-responsive seal (5) and the pipe sleeve (2) work together to ensure that the fluid inside the sealed pipe does not seep; the seamless pipe with grooves on the head ( 1) A guide liner (6) is installed to limit the gap between the sleeve (2) and the seamless pipe (1) with grooves on the head, and reduce the bending moment or bias caused by the excessive gap at the connection position The pressure response type sealing (5) phenomenon also plays a guiding role during installation a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com