Fan fan-blade positioning structure

A positioning structure and fan blade technology, which is applied to components of pumping devices for elastic fluids, non-variable pumps, machines/engines, etc., can solve the problem of reducing the service life and quality of fans, affecting bearings and fan shafts Core life, occupied structure space and other issues, to achieve the effect of improving the strength of the shaft core and fan quality, improving the rotation stability, and reducing the overall height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

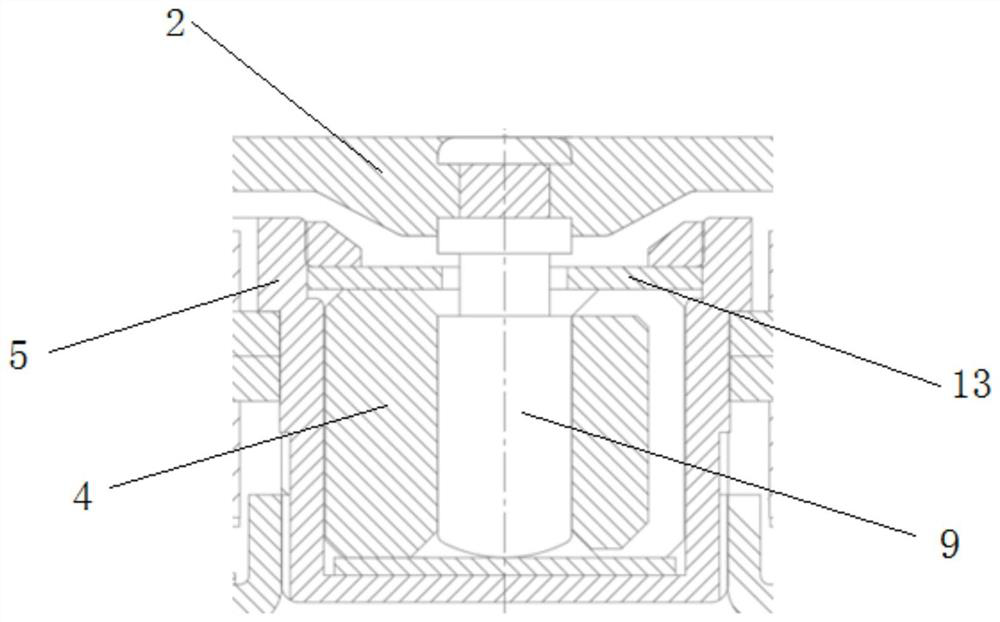

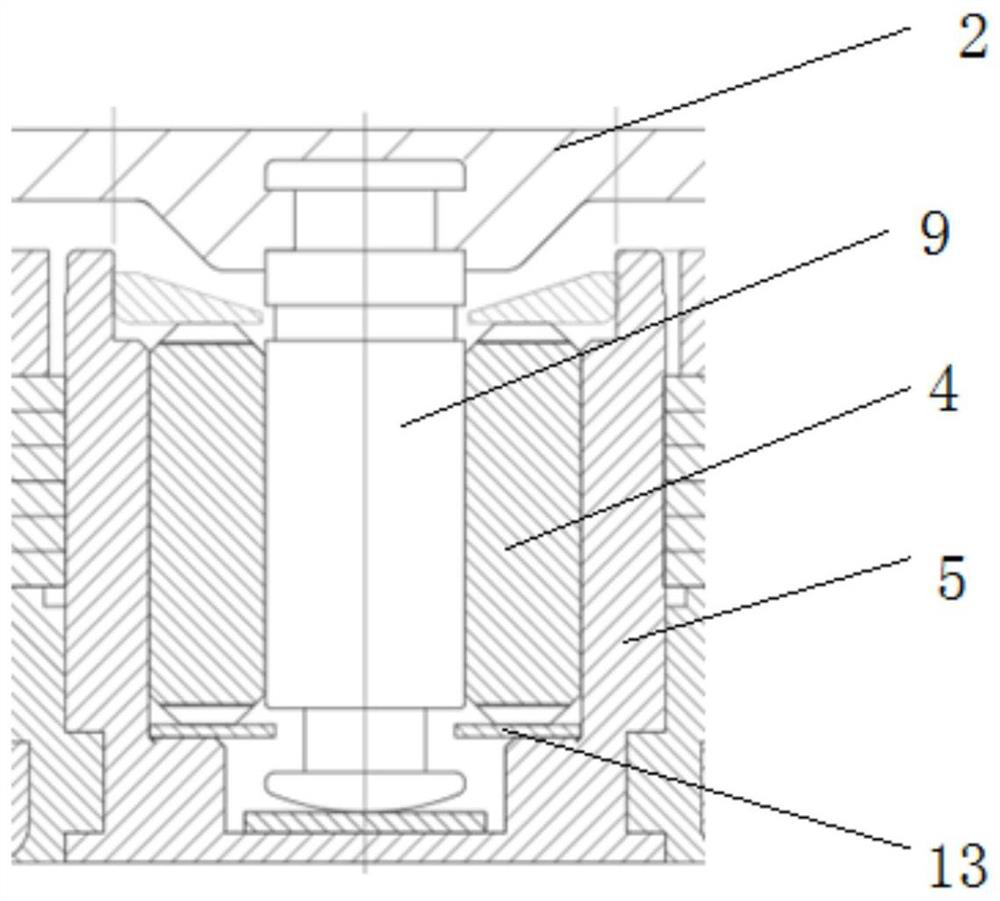

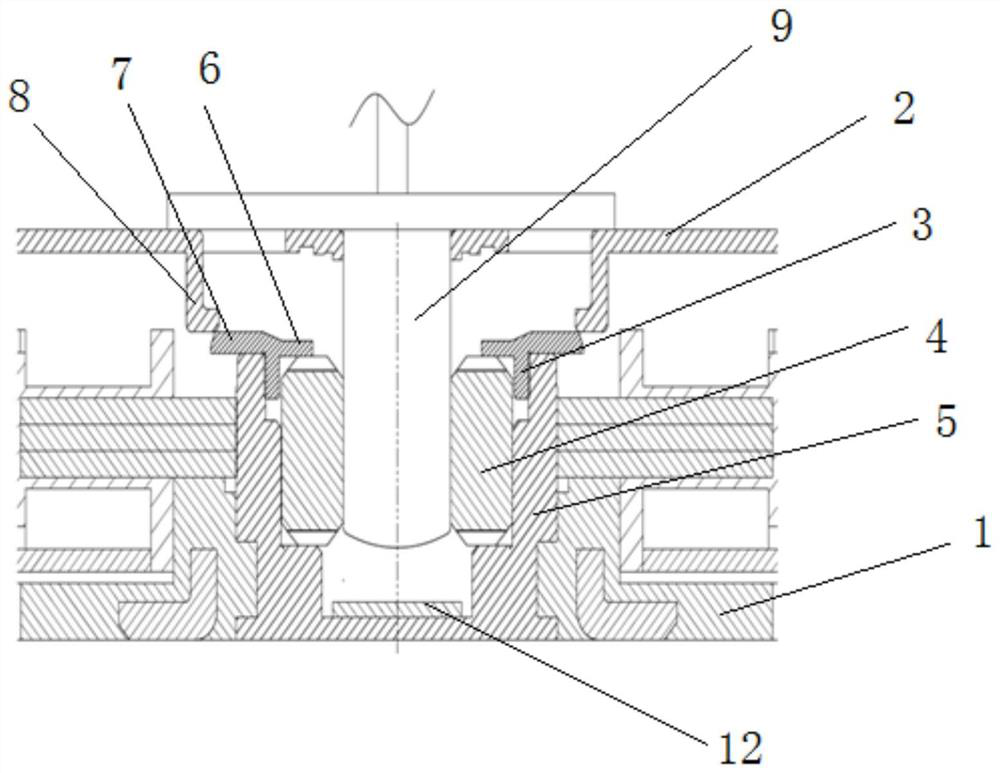

[0025] Example: Please refer to image 3 , 4 As shown, a fan blade positioning structure includes a fan housing 1, a fan blade 2, a positioning ring 3, a bearing 4 and a middle tube 5, the middle tube 5 is fixedly installed in the fan housing 1, and the bearing 4 is inserted In the middle tube 5, the positioning ring 3 is fixedly installed on the middle tube 5, and the positioning ring 3 is axially stopped with a limit stop wall 6 and a first buckle 7, and the limit stop wall 6 extends radially. Into the inner side of the middle tube 5 and stop on the upper end surface of the bearing 4, the second buckle 8 is fixed on the motor housing of the fan blade 2, and the second buckle 8 and the first buckle 7 can axially stop And the fastening connection of relative rotation in the circumferential direction. In this structure, the first buckle 7 is designed on the positioning ring 3, and the second buckle 8 is designed on the motor housing of the fan blade 2. Through the first buckl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com