Use of assembled N-Ag-TiO2-ZnO nano cage in methylyellow degradation reaction under visible light

A technology of nanocage and methyl yellow, which is applied in the direction of light water/sewage treatment, physical/chemical process catalyst, special compound water treatment, etc., can solve the problems of reducing energy barriers, achieve enhanced photocatalytic ability, expand absorption length and The effect of depth, excellent efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention is illustrated below through the preferred embodiments. It should be understood by those skilled in the art that the examples are only used to illustrate the present invention and not to limit the scope of the present invention.

[0039] In the examples, unless otherwise specified, the means used are conventional means in the art.

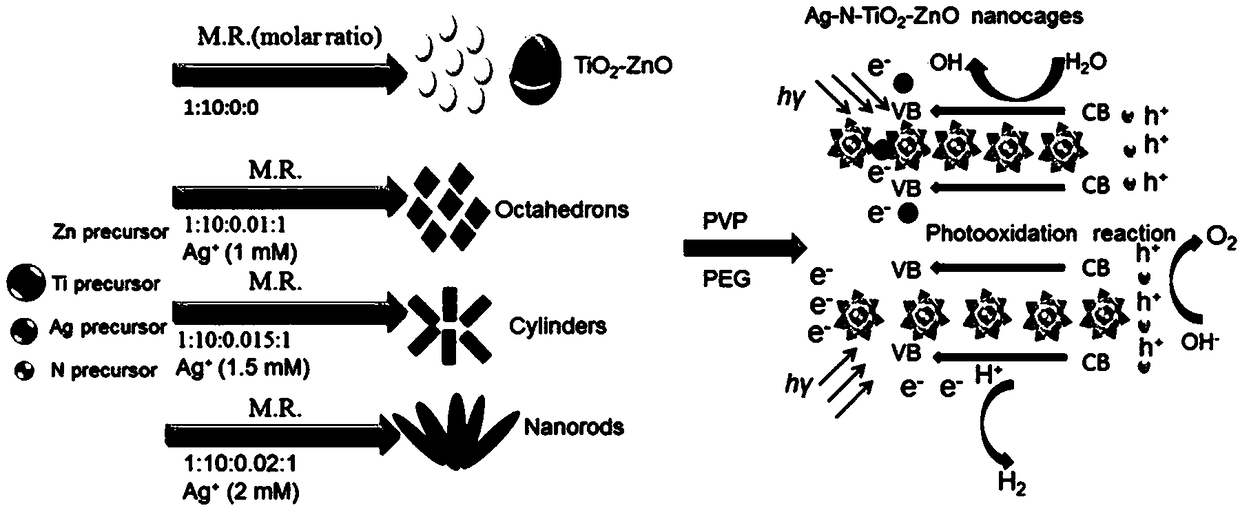

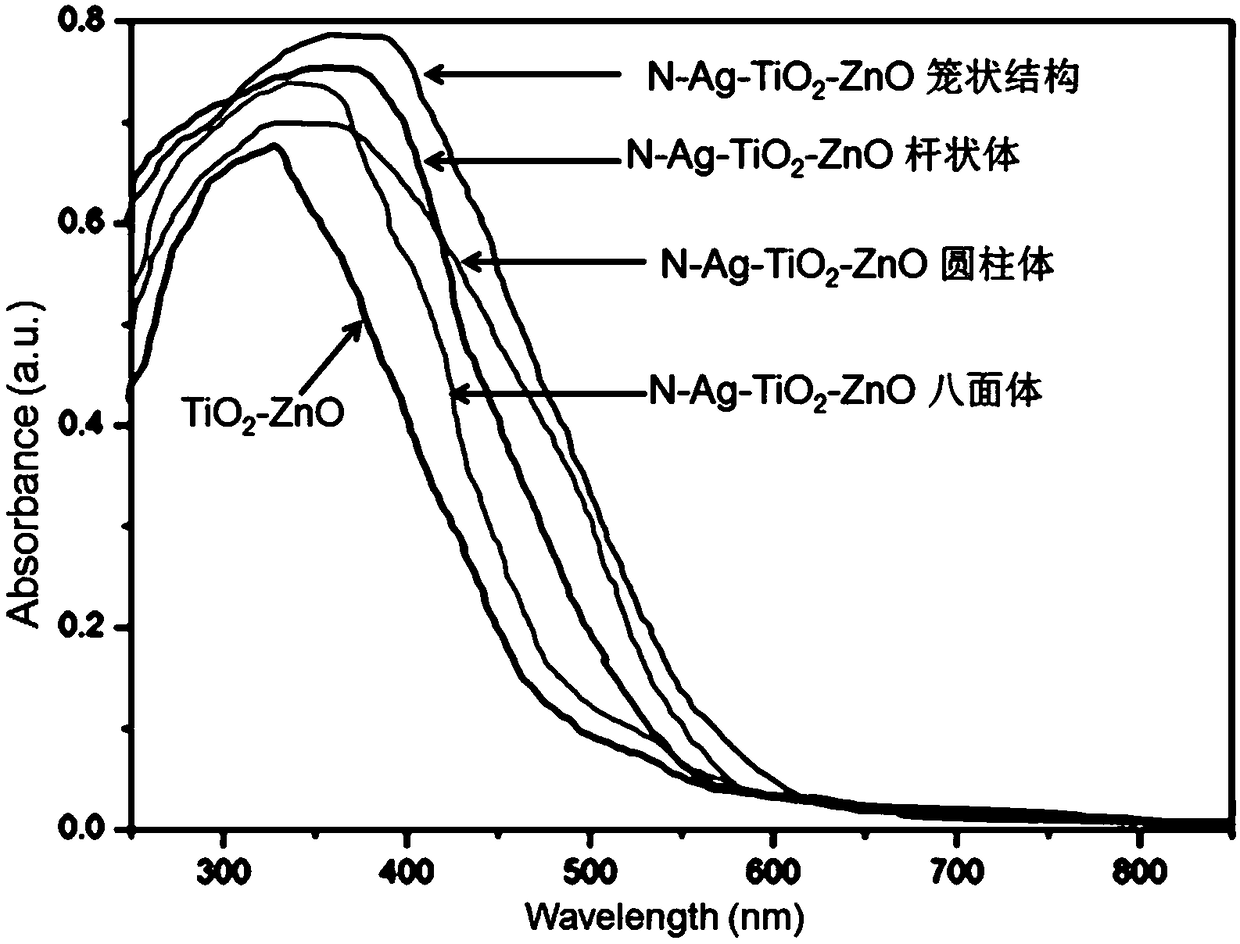

[0040] 1. A polymer-assisted method to assemble N-Ag-TiO 2 -ZnO nanocage structure for the degradation of methyl yellow under visible light. The separation mechanism of photocatalytic electrons and holes and the degradation mechanism of methyl yellow were investigated. The method comprises the following steps: preparing the required precursors of the nanocages through regulation and control, including regular octahedrons, cylinders and rod-like structures. These heterogeneous core structures were prepared by controlling the concentration of Ag while exploring their growth mechanism. These heterogeneous core structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com