Extraction method of vegetable protein

An extraction method and plant protein technology, which is applied in the field of plant protein extraction, can solve the problems of low protein yield, low protein purity, and damage to the spatial structure, and achieve the goals of reducing NaCl crystals, high protein purity, and high extraction rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

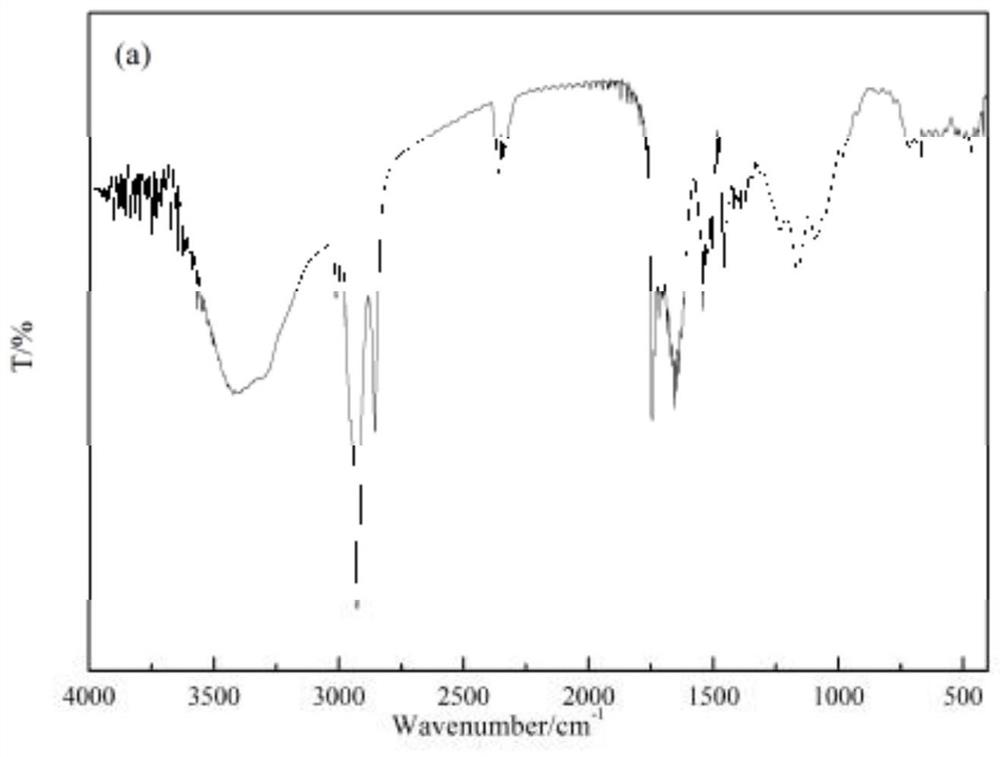

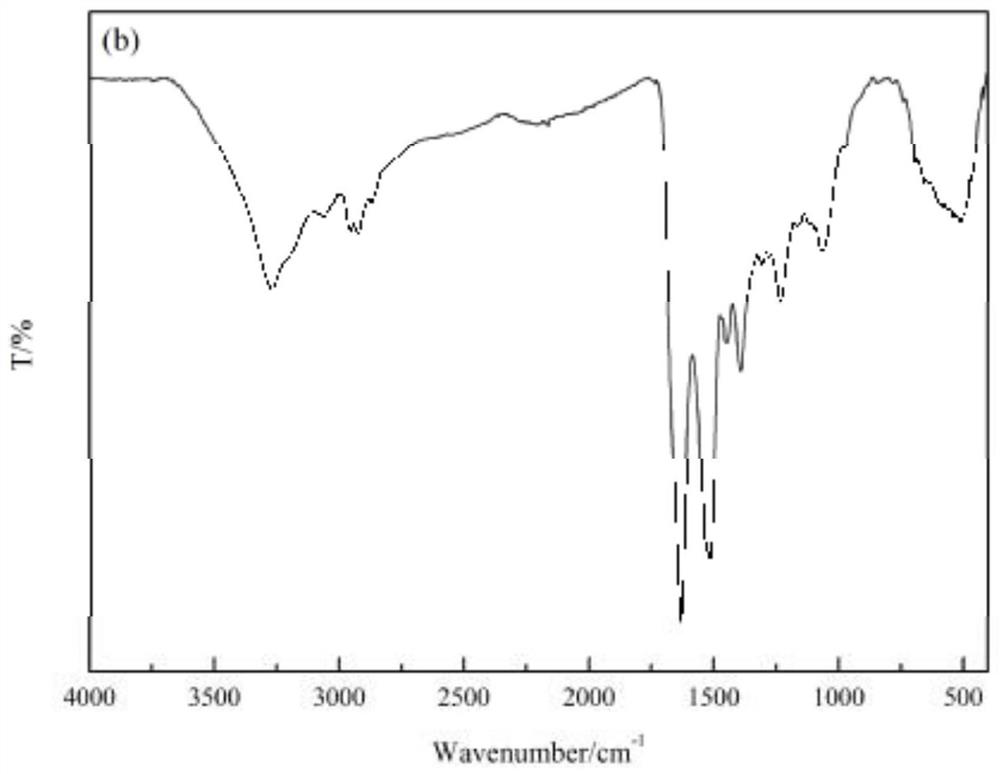

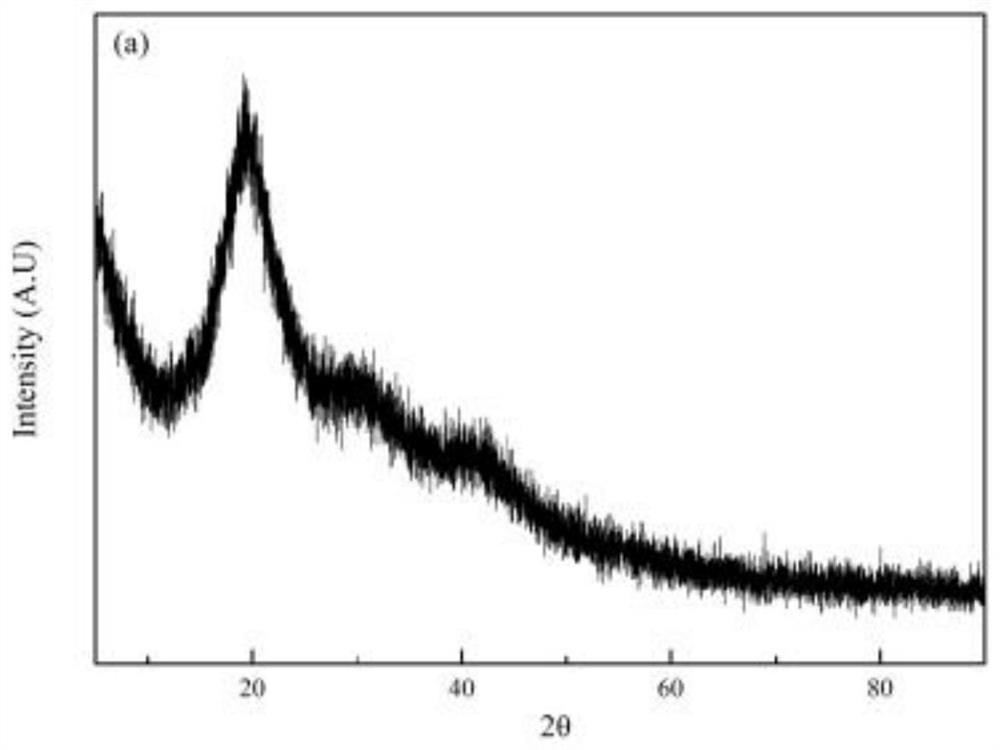

Image

Examples

Embodiment 1

[0031] Use a high-speed grinder to crush the hemp seeds, pass through a 40-mesh sieve, use n-hexane as a solvent, add n-hexane at a material-to-liquid ratio of 1:4, mechanically stir for 30 minutes, then centrifuge at 5600xg for 10 minutes, and continue to operate in this way for insoluble matter After degreasing for 3 times, dry it, take 100g of degreased hemp seed powder and add deionized water according to the ratio of material to liquid 1:20, use NaOH solution to adjust the pH to 10.0, stir mechanically for 2 hours, during which the pH of the solution is detected every 15 minutes and ensure Its value is 10.0, after centrifugation at 5600xg for 10 minutes, the supernatant is placed in an electric field, graphite is used as the anode plate, titanium alloy is used as the cathode plate, the power supply voltage is adjusted to 15V, and the distance between the plates is 10cm. After 60 minutes, the power was turned off, and the collected flocs were vacuum freeze-dried at -48°C fo...

Embodiment 2

[0034] Use a high-speed grinder to crush the hemp seeds, pass through a 60-mesh sieve, use petroleum ether as a solvent, add petroleum ether according to the ratio of material to liquid 1:3, mechanically stir for 30 minutes, then centrifuge at 5600xg for 10 minutes, and continue to operate in this way for insoluble matter After degreasing for 3 times, dry it, take 100g of degreased hemp seed powder and add deionized water according to the ratio of material to liquid 1:15, use NaOH solution to adjust the pH to 10.5, stir mechanically for 2 hours, during which the pH of the solution is detected every 15min and ensure Its value is 10.0, after centrifugation at 5600xg for 10 minutes, the supernatant is placed in an electric field, graphene is used as the anode plate, titanium alloy is used as the cathode plate, the power supply voltage is adjusted to 30V, and the plate spacing is 8cm, and the cathode plate and its vicinity are collected every 10 minutes. After 10 minutes, the power...

Embodiment 3

[0036] Use a high-speed pulverizer to crush the quinoa seeds, pass through a 40-mesh sieve, use n-hexane as a solvent, add n-hexane at a material-to-liquid ratio of 1:2, mechanically stir for 30 minutes, then centrifuge at 5600xg for 10 minutes, and continue to operate in this way for insoluble matter After degreasing for 3 times, dry it, take 100g of degreased quinoa powder and add deionized water according to the ratio of material to liquid 1:15, use NaOH solution to adjust the pH to 9.0, stir mechanically for 2 hours, during which the pH of the solution is detected every 15min and ensure its The value is 9.0, then centrifuged at 5600xg for 10 minutes, the supernatant is placed in an electric field, graphite is used as the anode plate, and copper alloy is used as the cathode plate. After 40 minutes, the power was turned off, and the collected flocs were vacuum freeze-dried at -48°C for 12 hours to obtain quinoa seed protein isolate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com