Stone carrying device and diamond wire stone cutting machine

A bearing device and diamond wire technology, applied in stone processing equipment, stone processing tools, metal processing equipment, etc., can solve problems such as unstable support, stone movement, troublesome operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] In order to further explain the technical solution of the present invention, the following will be described in detail in conjunction with the examples.

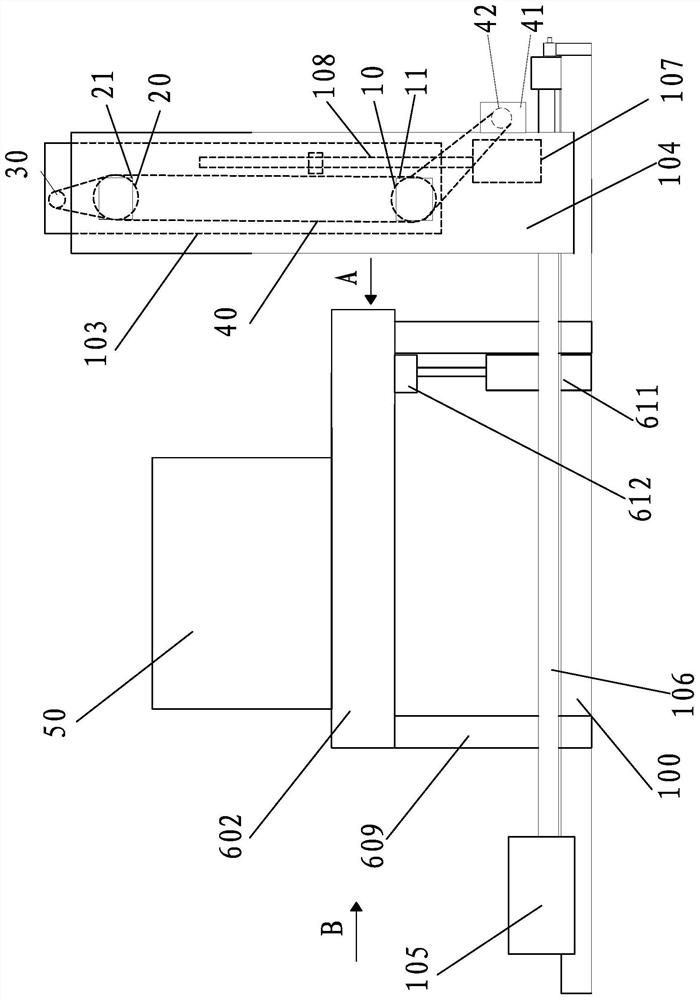

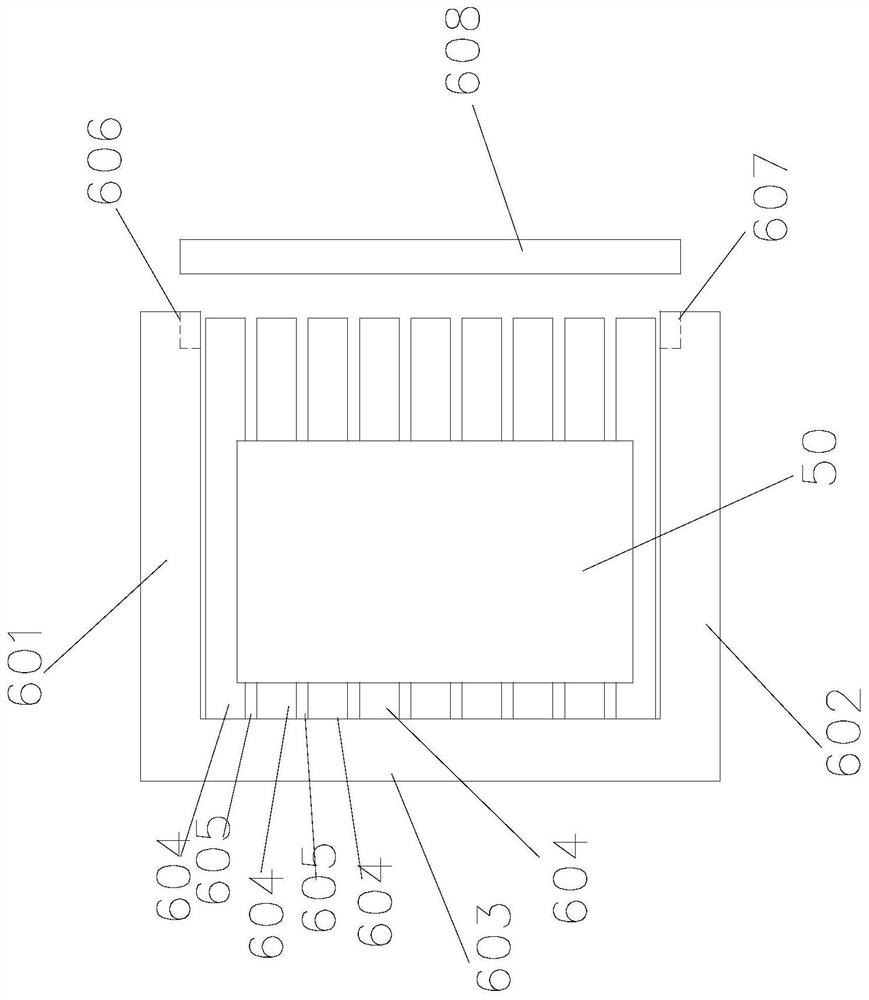

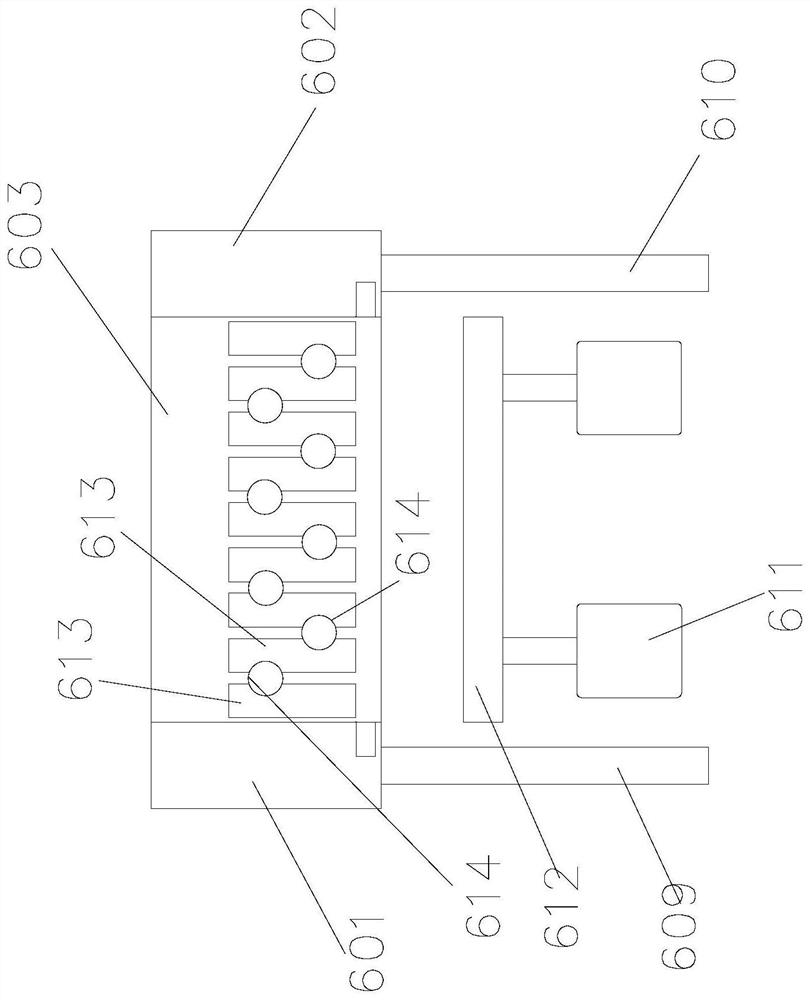

[0075] refer to Figure 1 to Figure 12 , the present invention proposes a stone bearing device, including a bracket and a plurality of support plates 604 arranged on the bracket, a strip-shaped seam 605 for diamond wire walking is formed between adjacent support plates 604, and one end of the support plate 604 It is arranged on the bracket, and the other end is a free end, and also includes a supporting mechanism for supporting the free end, and the supporting mechanism is set in a manner that can be moved away from the free end and corresponding to the free end.

[0076] As a preferred mode of the present invention, the supporting mechanism includes a supporting plate 612 and a lifting mechanism for driving the supporting plate 612 up and down, the supporting plate 612 is arranged below the free end, and the supporti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com