Rusting prevention method based on surface rust removing of figured steel structure

An anti-corrosion, steel structure technology, applied in the direction of grinding machine tool components, manufacturing tools, grinding drive devices, etc., can solve the problem of uneven surface treatment during the grinding process of hand grinders, to prevent peeling and loss of anti-corrosion The effect of rust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

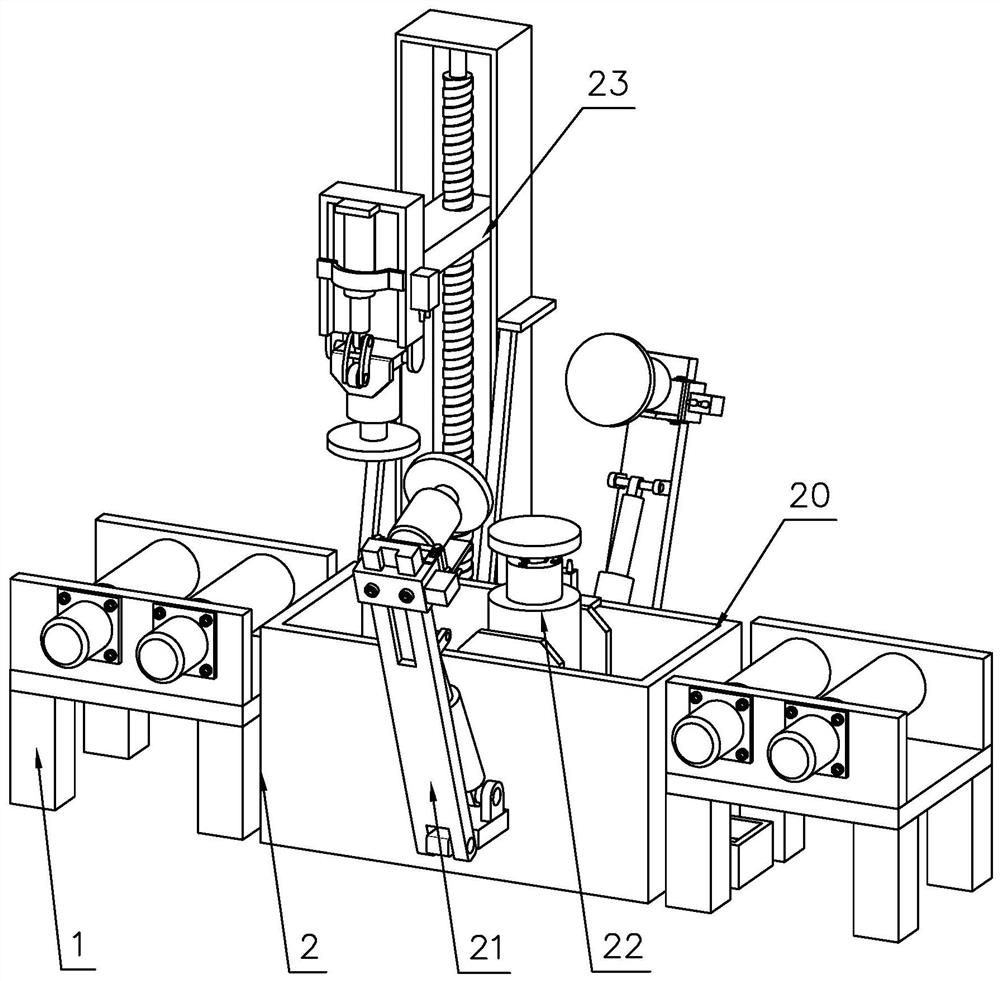

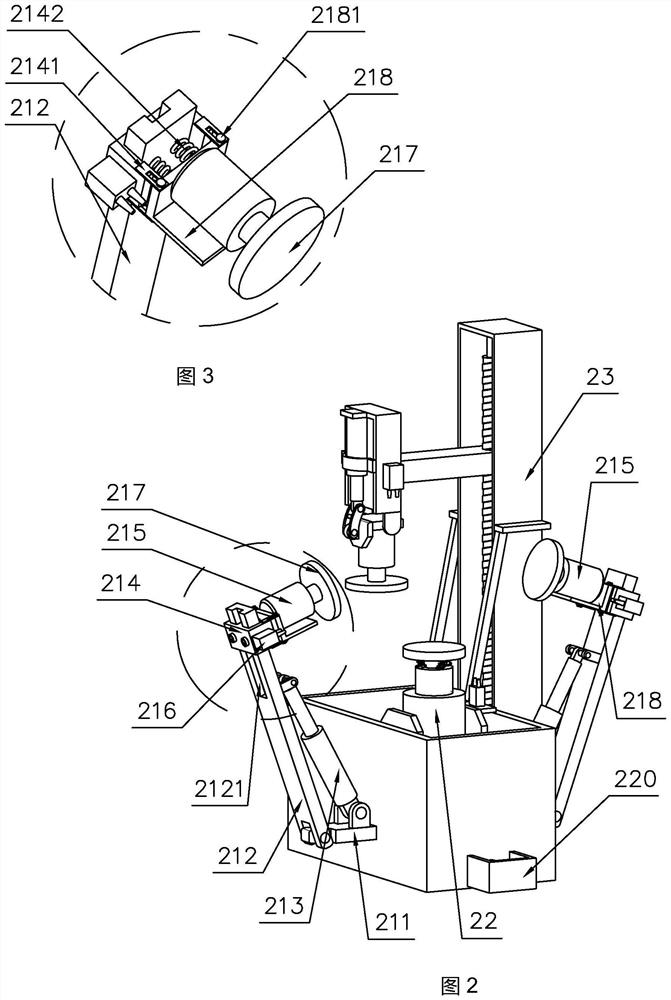

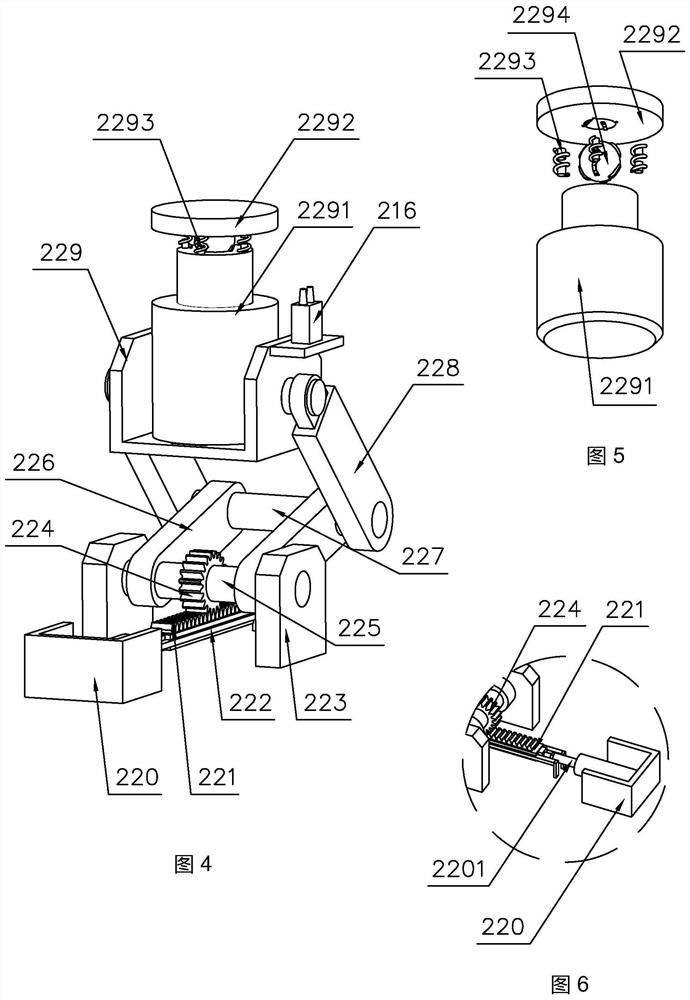

[0045] To facilitate the understanding of those skilled in the art, the following is attached. Figure 1-8 The technical scheme of the present invention will be further explained in detail.

[0046] An anti-rust method based on the surface rust removal of special-shaped steel structure includes the following steps:

[0047] 1, surface dust treatment, namely, comprehensively dedusting the I-beam through a high-pressure jet pipe;

[0048] Step 2, side surface impurity treatment, i.e., side surface impurity treatment is carried out on the I-beam subjected to dust removal in step 1, and the side surface comprises the outer end surfaces of both sides of the rib plate in the middle of the I-beam and the outer end surfaces of the wing plates;

[0049] Step 3, bottom impurity treatment, which further carries out bottom impurity treatment on the I-beam whose side surface impurity treatment is completed in step 2;

[0050] Step 4, top surface impurity treatment, i-beam top surface impurity t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com