Integrated machining equipment for tractor bionic exhaust tail pipe

A technology for exhaust tailpipes and processing equipment, which is applied to other manufacturing equipment/tools, manufacturing tools, etc., and can solve problems such as time-consuming, labor-intensive processing, high labor costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

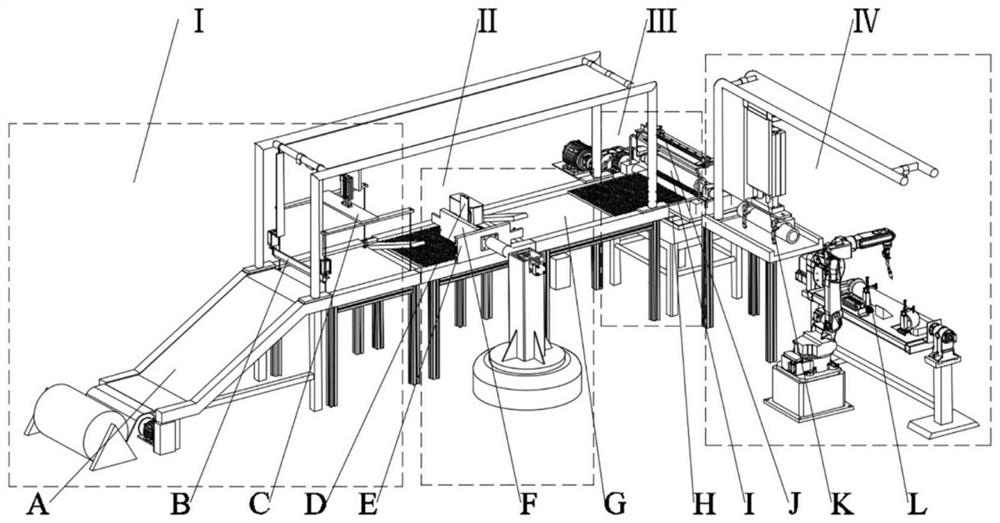

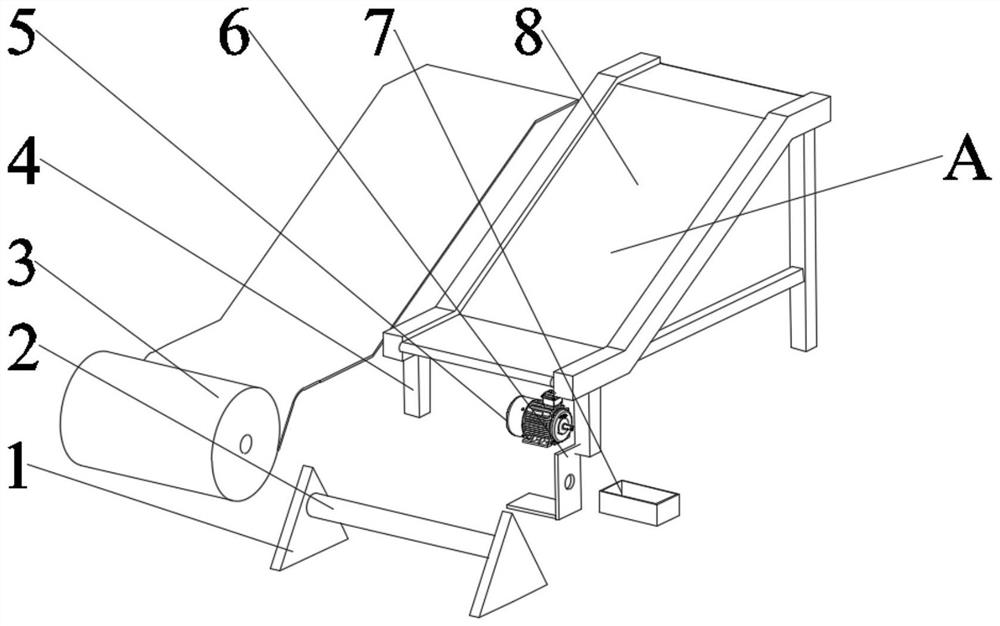

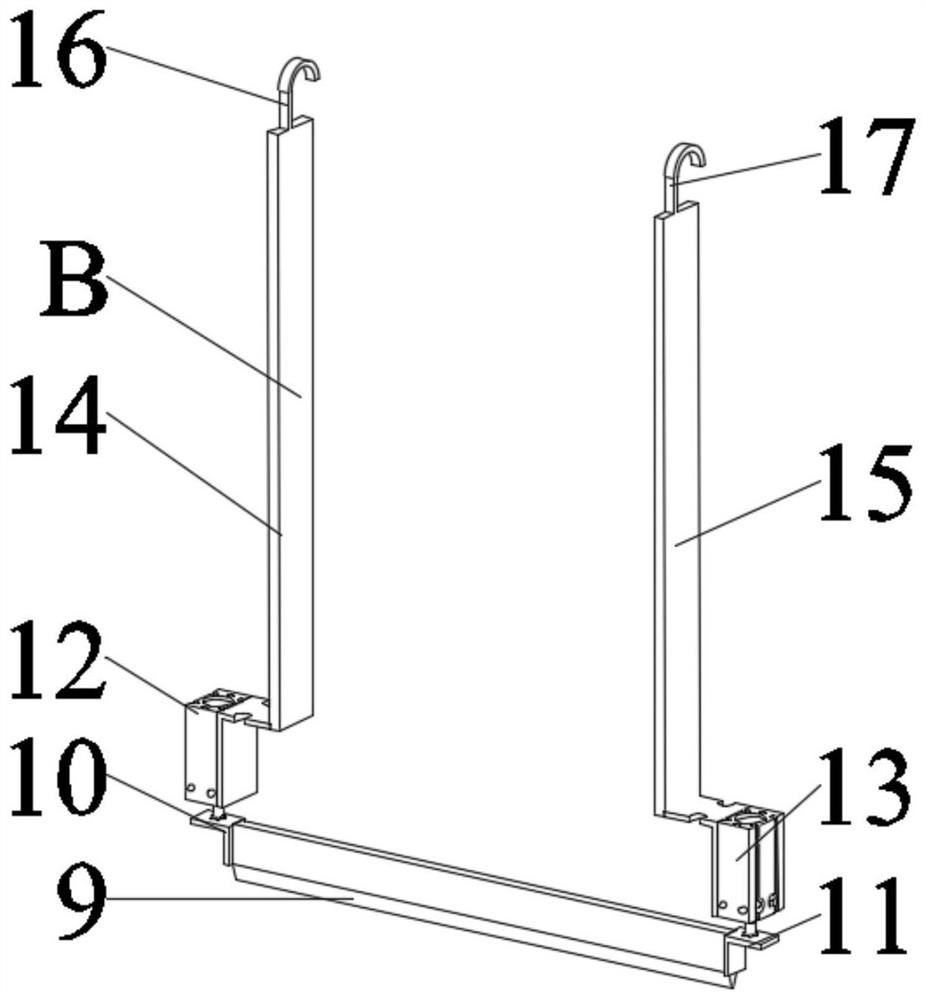

[0047] Such as figure 1 As shown, the present invention consists of feeding device I, texture processing device II, reel and welding device III, bend pipe and straight pipe welding device IV, steel plate conveying mechanism A, cutting mechanism B, pressing and adsorption mechanism C, cutter vertical Straight motion mechanism D, tool left and right movement mechanism E, tool forward and backward movement mechanism F, loading mechanism G, lifting mechanism H, reel and welding mechanism I, pipe pushing mechanism J, pipe clamping and transport mechanism K, pipe positioning and clamping Mechanism L, bracket a4, beam a19, bracket b33, bracket c34, bracket d64, bracket e65, bracket f104, cylinder rod a59, connecting plate g55, connecting plate f51, workbench b35, bottom plate 68, upper mounting plate b94, bow character Installation plate 70, steel frame b89, worktable c105, connecting plate h116, cantilever steel frame 106, base a120, base b121, connecting rib a123, motor d125, conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com