Automatic reset controller for toilet float

An automatic reset and controller technology, which is applied to flushing equipment with water tanks, water supply devices, buildings, etc., can solve the problems of manual reset of the float, time-consuming and laborious, and troublesome operation, and achieves a high degree of intelligence, low investment cost, The effect of easy wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

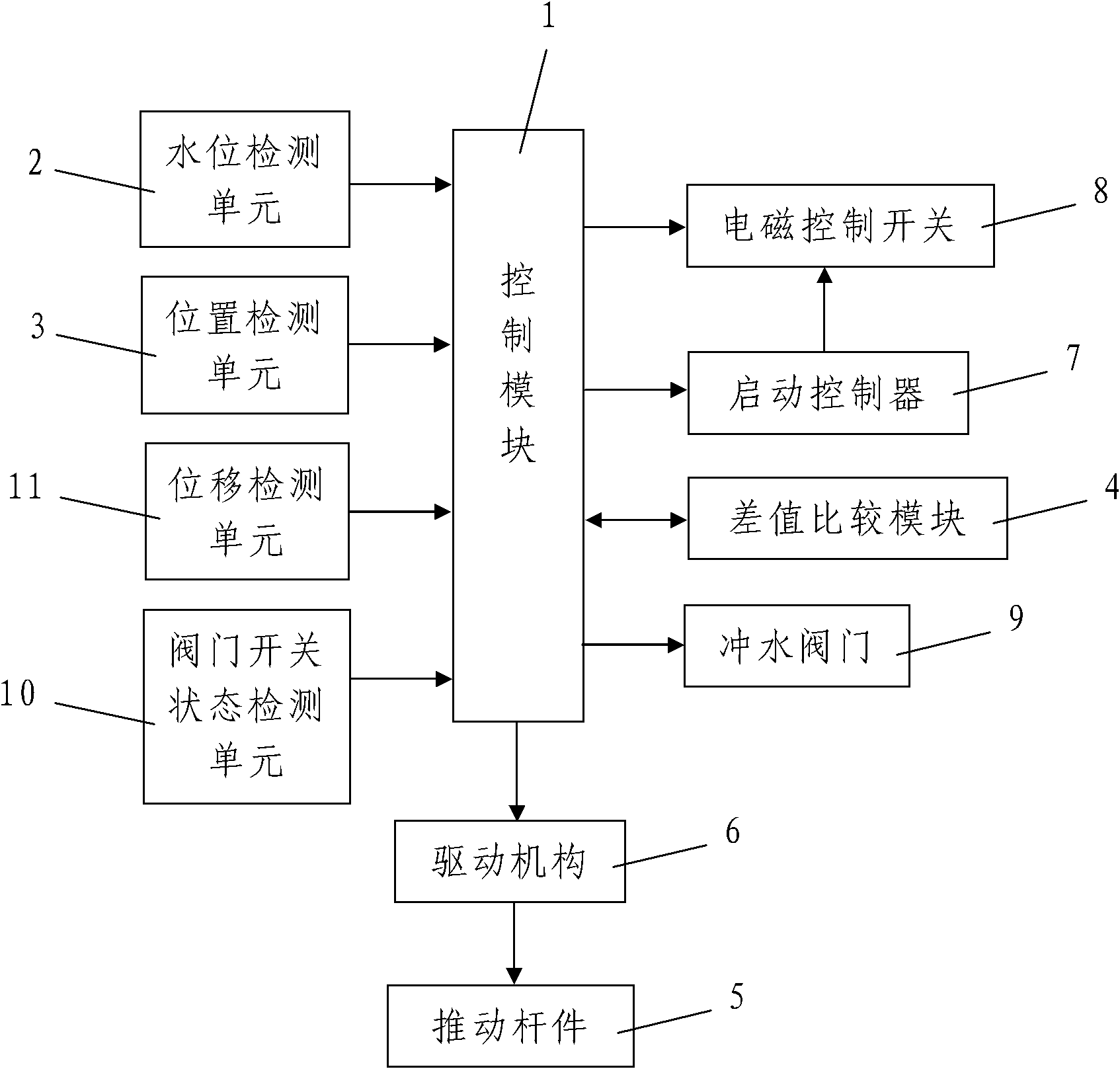

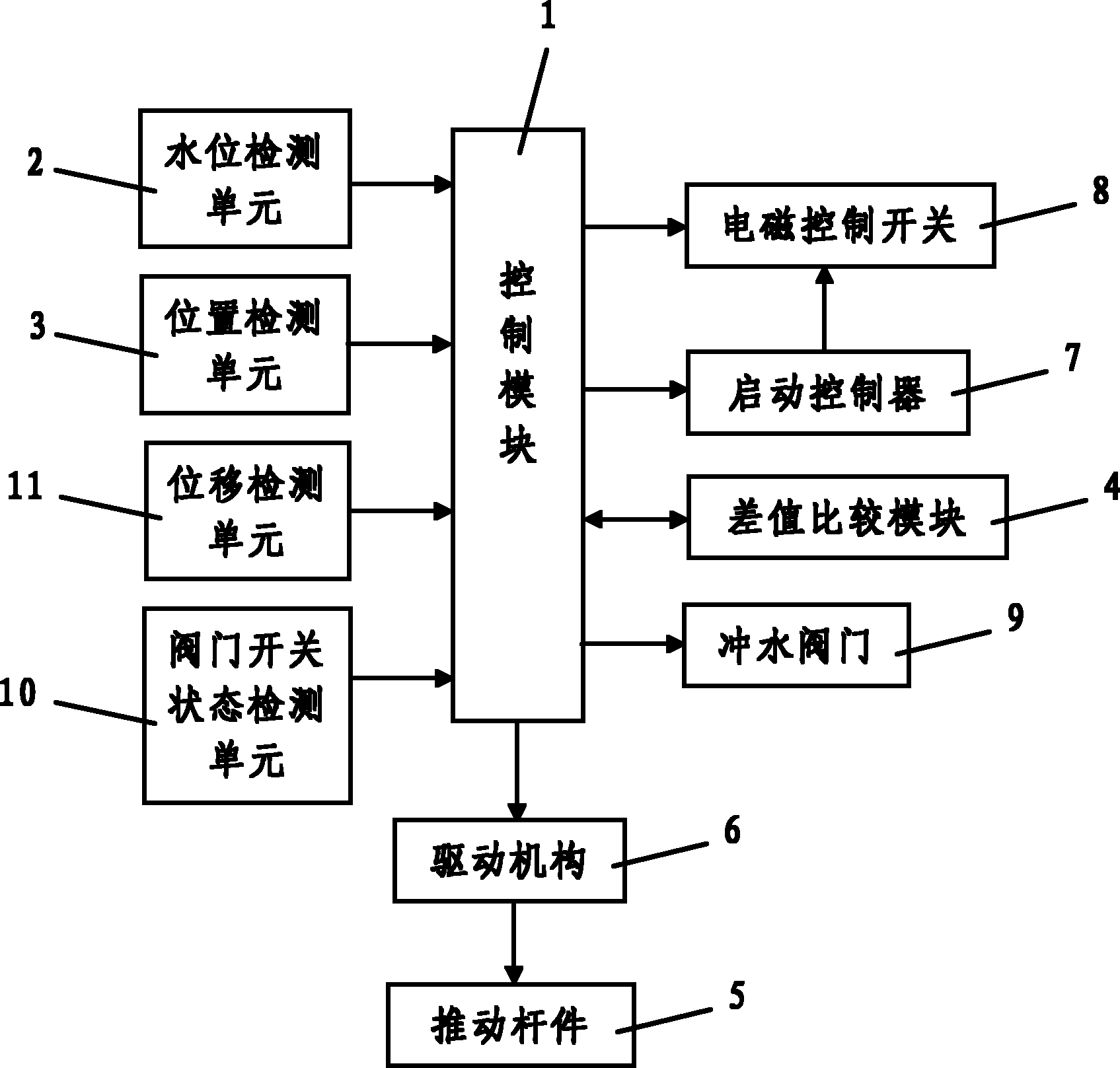

[0029] Such as figure 1 As shown, the present invention includes a control module 1, which detects the water level in the toilet water tank in real time and synchronously transmits the detected water level signal to the water level detection unit 2 of the control module 1, detects the position of the floating ball in the toilet water tank in real time and The detected position signal is synchronously transmitted to the position detection unit 3 of the control module 1, the difference comparison module 4 for comparing the difference between the signals detected by the water level detection unit 2 and the position detection unit 3, installed inside the toilet tank and The push rod 5 that pushes the ball up and down and the drive mechanism 6 that drives the push rod 5 to move up and down and is controlled by the control module 1, the drive mechanism 6 is connected to the control module 1 and the control module 1 compares the difference according to The difference comparison resul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com