Preparation method of grafted catalyst for continuous catalytic synthesis of isobutyl isobutyrate

A technology of isobutyl isobutyrate and catalysts, which is applied in the direction of organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, aldehyde redox preparation, etc., which can solve the large discharge of waste liquid and pollutants , poor catalyst stability, poor reusability and other problems, to achieve the effects of shortening industrial production steps, overcoming catalyst deactivation, good economy and industrial value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) First disperse 5.0g of NMC in 100mL of sulfuric acid washing solution (volume ratio H 2 SO 4 :H 2 o 2 =3:1), put it in an ultrasonic cleaner for 2 hours, and then stir it at 80°C for 2 hours; finally, wash the NMC repeatedly with distilled water until neutral, and dry it overnight at 60°C. The treated carrier is designated as NMC-A.

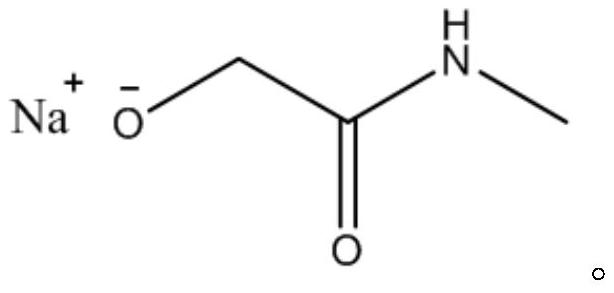

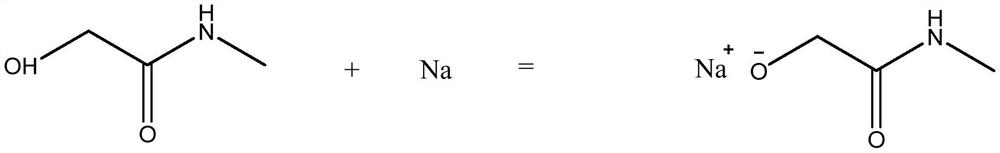

[0023] (2) Put 1.5 g of 2-hydroxy-N-methylacetamide into a container at 60° C. and heat it, protect it with nitrogen and add 2 g of elemental sodium, stir for 6 hours and filter to obtain organic sodium salt.

[0024] (3) 1.5 g of the filtered organic sodium salt and 5 g of the acidified carrier were put into ethanol and stirred for 5 hours. The catalyst was prepared by filtering and drying overnight at 60°C.

[0025] Weigh 50 grams of the catalyst, put it into a reaction tube, feed isobutyraldehyde into the fixed-bed reactor at a flow rate of 1 L / min, press 0.2 MPa, raise the temperature of the heating furnace from room temperatu...

Embodiment 2

[0027] In the step (1), the concentration of washing liquid is (H 2 SO 4 :H 2 o 2 =2:1) instead of the concentration of lotion in embodiment 1 is (H 2 SO 4 :H 2 o 2 =3:1), other steps are with embodiment 1.

Embodiment 3

[0029] In the step (1), the concentration of washing liquid is (H 2 SO 4 :H 2 o 2 =4:1) instead of the concentration of lotion in embodiment 1 is (H 2 SO 4 :H 2 o 2 =3:1), other steps are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com