Double-needle lockstitch sewing machine

A technology of lockstitch sewing machine and machine base, which is applied to sewing machine components, sewing machine casings, sewing machine collar mechanisms, etc., and can solve problems such as inability to form flat seams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

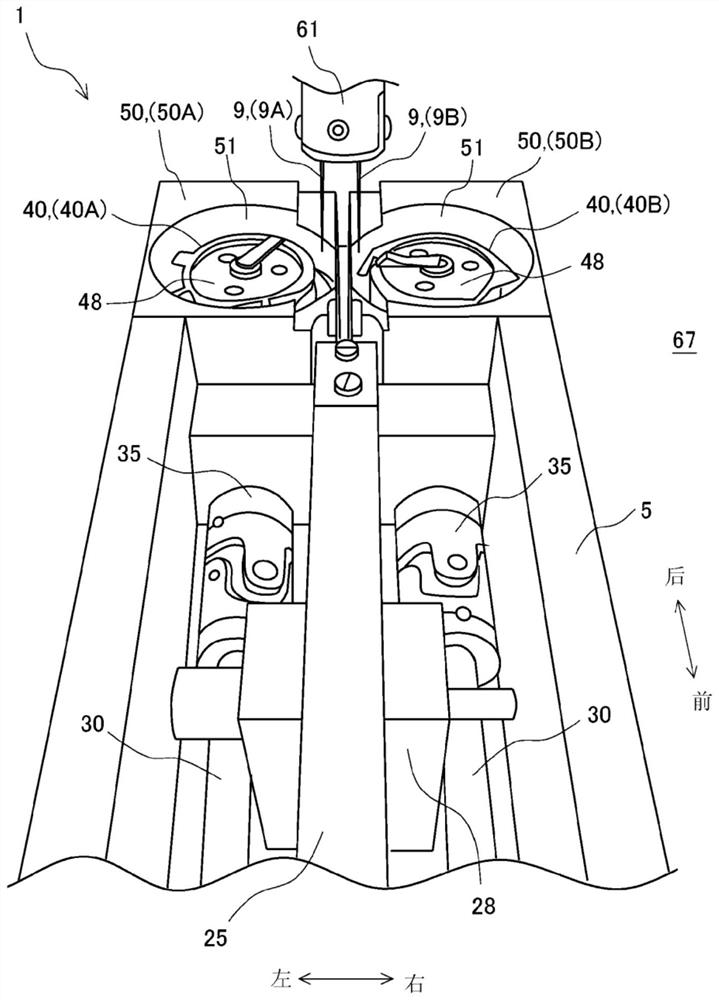

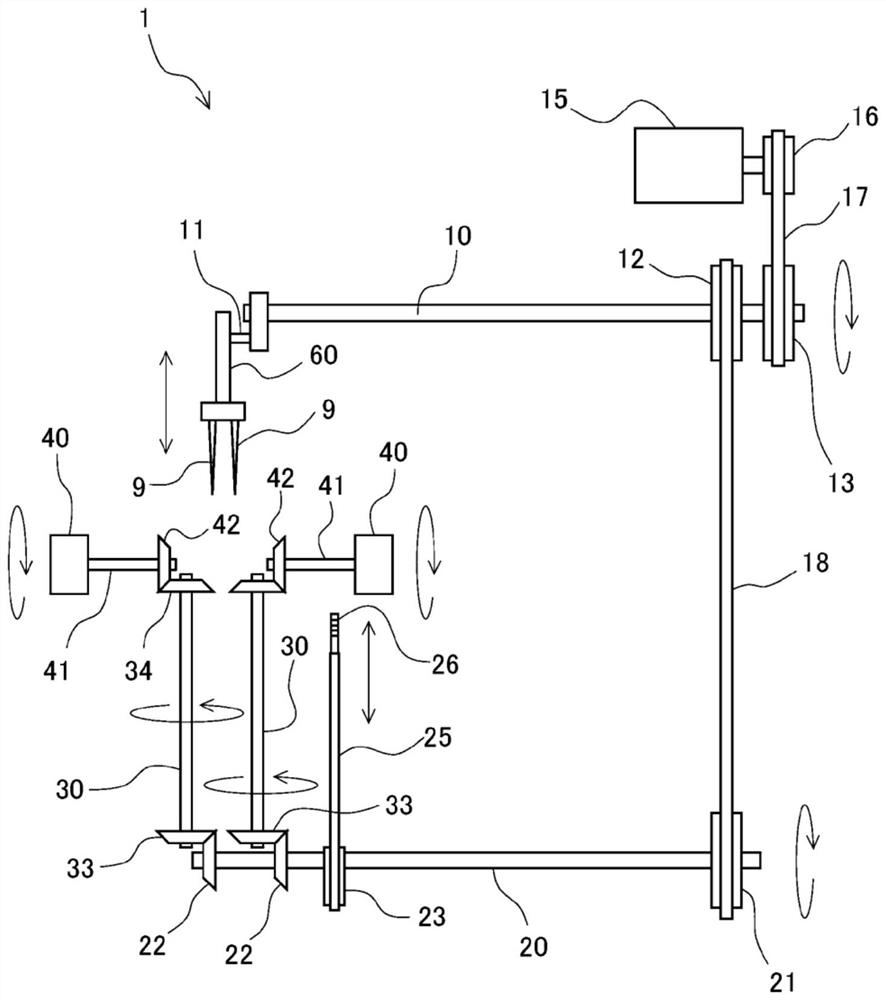

[0038] Hereinafter, a two-needle lockstitch sewing machine according to an embodiment of the present invention will be described in detail based on the drawings.

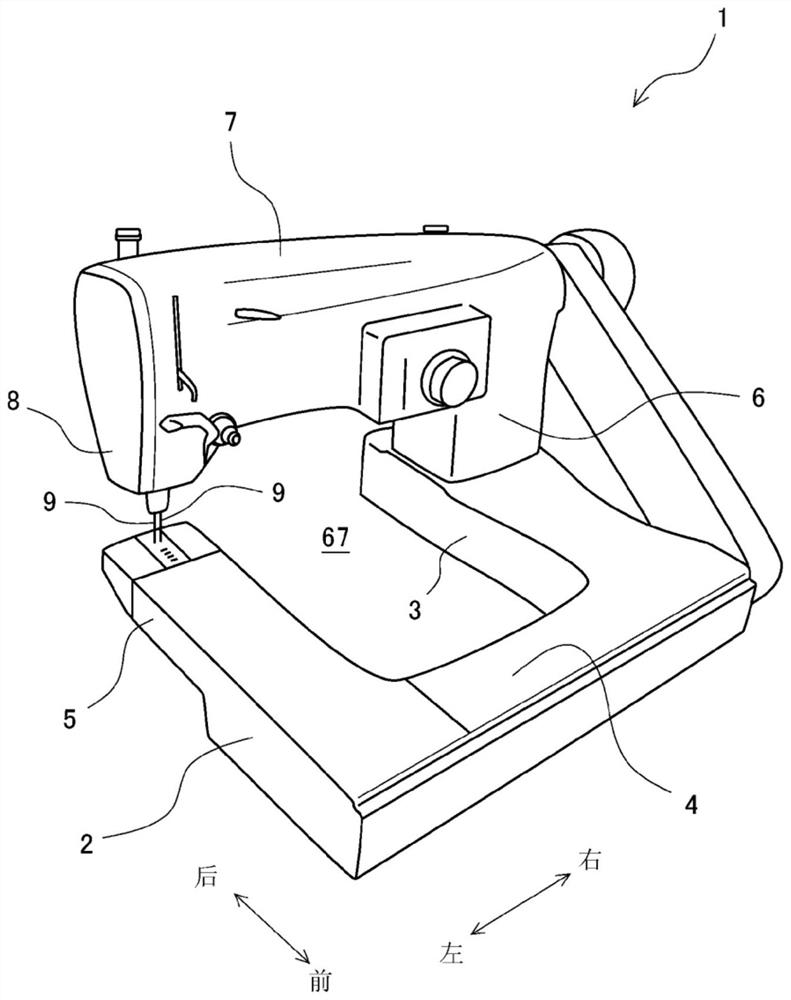

[0039] figure 1It is a perspective view of the twin-needle lockstitch sewing machine 1 according to the embodiment of the present invention. In addition, in the following description, the front side of a cloth feeding direction is called "front", and the back side is called "back" suitably. In addition, "left" and "right" used suitably in description mean the direction based on the state which faced the cloth feeding direction.

[0040] The two-needle lockstitch sewing machine 1 is a lockstitch sewing machine suitable for sewing tubular objects such as sleeves of clothes. Such as figure 1 As shown, the double-needle lockstitch sewing machine 1 has adopted a base portion 2, a pillar portion 6 erected upward from the base portion 2, an upper arm portion 7 disposed on the upper portion of the pillar portion 6, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com