Controlled Splitting of Liquid Reflux in Dividing Wall Columns

A technology of dividing wall column and liquid reflux, applied in distillation regulation/control, separation/purification of carbonyl compounds, fractional distillation, etc., can solve problems such as increasing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

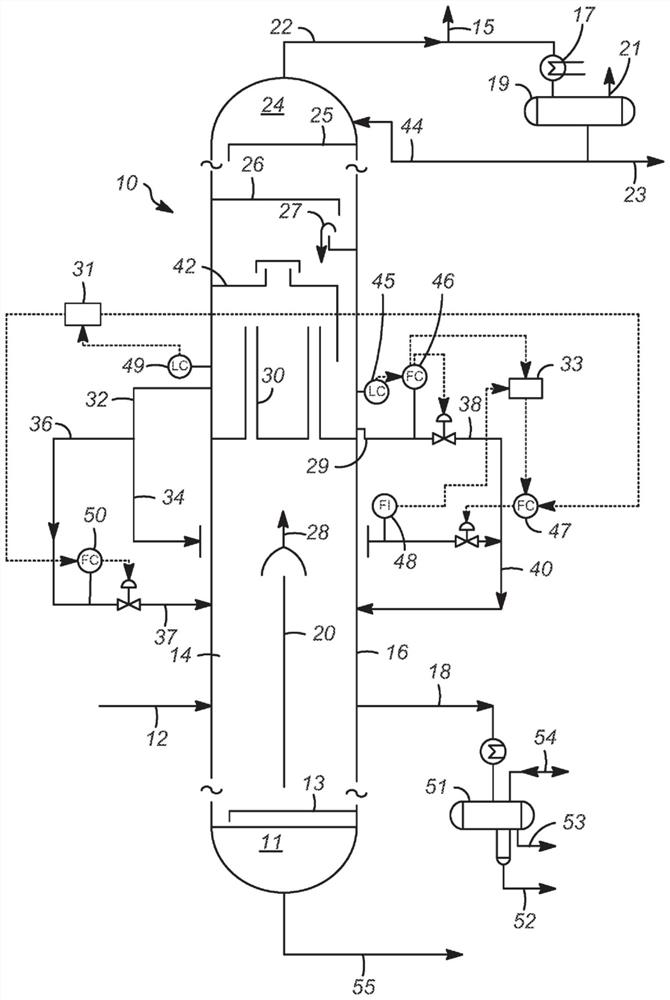

[0033] The first embodiment is a process comprising a divided wall column 10 having a feed side 14 and a product side 16, wherein the feed side includes an inlet for feed stream 12, and wherein the product side includes an inlet for liquid Product line outlet for side draw stream 18; wherein liquid reflux stream 27 from first active distillation tray 26 above dividing wall 20 forms or may form two liquid phases, wherein the two liquid phases of the reflux stream pass through any Means separation, wherein the reflux stream 29 comprising mainly the aqueous phase is directed integrally to the product side of the dividing wall, and the reflux stream 32 comprising mainly the organic phase is split into streams 34 and 36, wherein the stream 34 is directed as reflux to the product side, and stream 36 is directed as reflux to the feed side, wherein for the split phase streams, the flow distributed to the product side relative to the feed side is controlled.

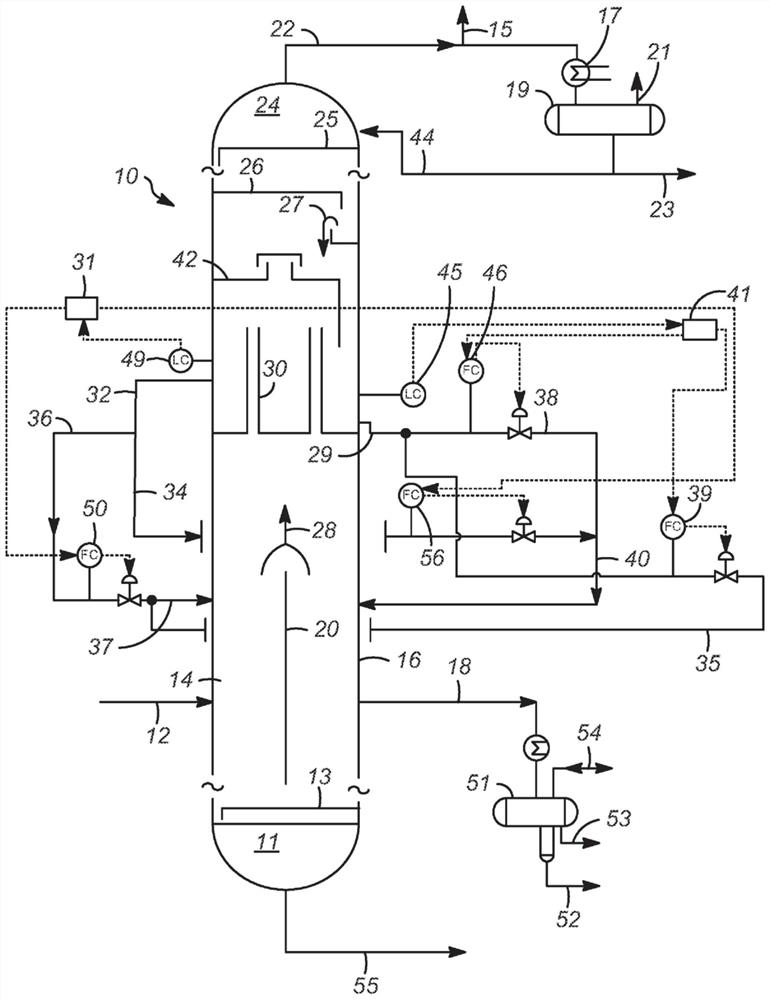

[0034] A second embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com