A battery lock box for a new energy vehicle

A new energy vehicle, battery locking technology, used in secondary batteries, battery pack components, battery temperature control and other directions, can solve the problems of poor temperature isolation, inconvenience, battery pack fixing, etc., to improve the effect of heat absorption , The operation is simple and convenient, and the effect of ensuring the battery life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

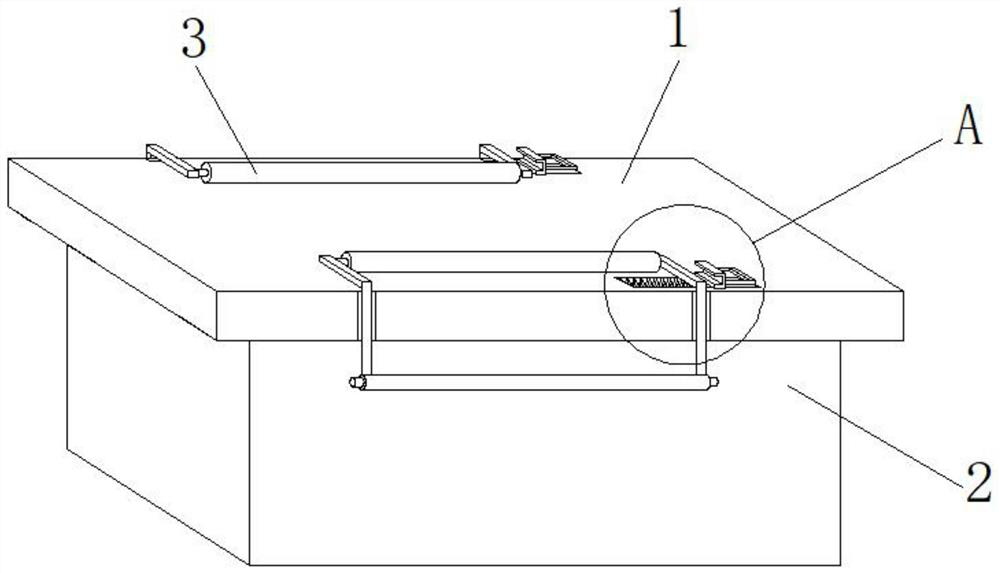

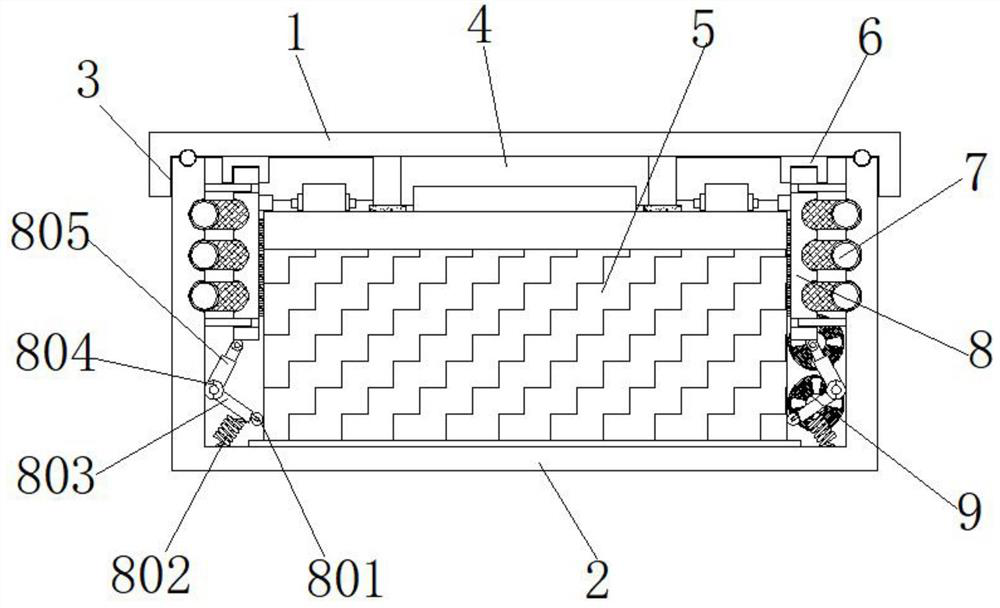

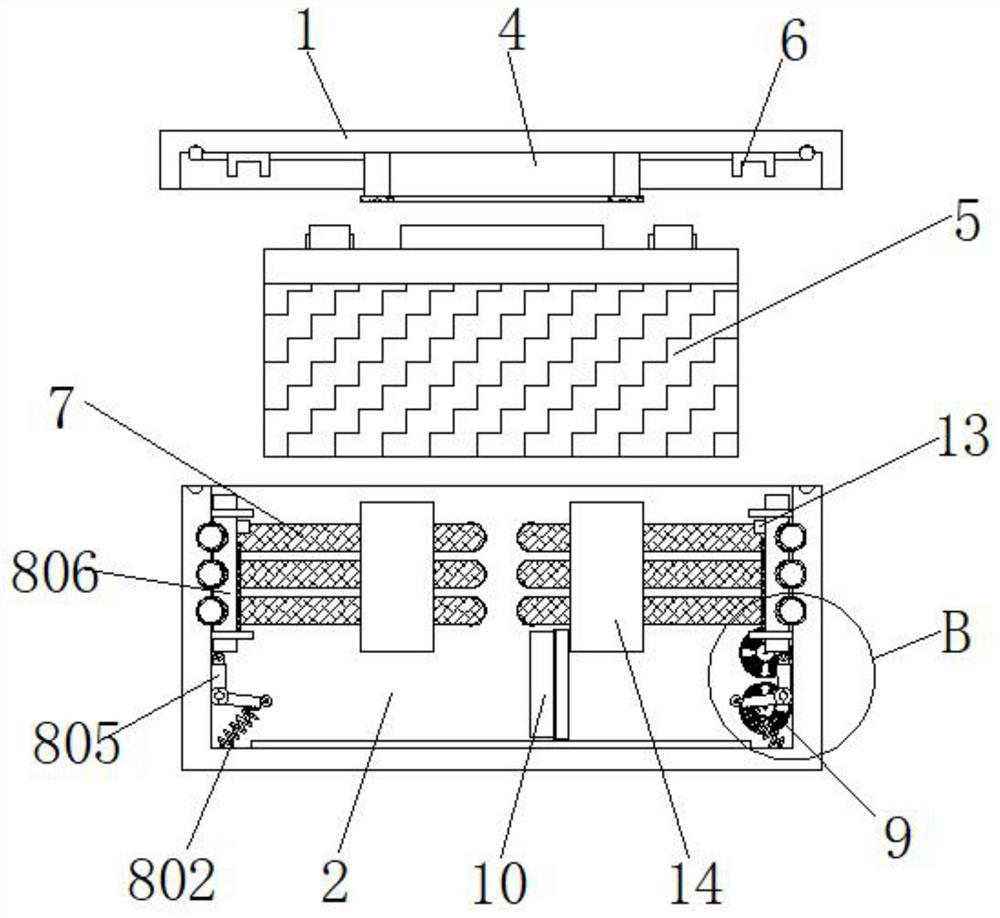

[0033] Example 1, such as Figure 1-7 As shown, when the battery assembly 5 needs to be put into the interior of the main body box 2, the card slot 301 is manually pulled so that the L-shaped bracket 303 leaves the inner side of the card slot 301, and then the two sets of L-shaped brackets 303 are manually opened downwards. , release the fixing effect on the cover plate 1, then open the cover plate 1, hold the handle on the battery assembly 5, and slowly put the battery assembly 5 into the inside of the main box 2, and when the battery assembly 5 enters the main box 2 , the outer side of the battery assembly 5 is in contact with the roller 801, and forces the connecting rod 803 and the lifting rod 805 to rotate around the hinge shaft 804. It is closely attached to the outside of the battery assembly 5, so that the battery assembly 5 is clamped and fixed.

Embodiment 2

[0034] Example 2, such as figure 2 , 3 As shown in , 4, 6 and 7, when the new energy vehicle is used in summer, the water pump 16 and the fan 9 are controlled to start working through the external control panel, so that the coolant inside the coolant tank 15 enters into the three sets of heat exchange tubes 7 inside, and then flow back to the inside of the coolant tank 15 through the water pump 16, so that the coolant can circulate and use the coolant to absorb the heat inside the main body case 2, and the fan 9 makes the air inside the main body case 2 circulate in the battery It flows in the gap between the component 5 and the main box 2, that is, it flows around the battery component 5 and enters the interior of the installation compartment 11 from the air inlet 10, and then the fan 9 blows air into the battery component 5 and the main box 2 In the gap between them, the circulation of air is formed, and the heat absorption effect of the cooling liquid is correspondingly i...

Embodiment 3

[0035] Example 3, such as image 3 , 4 As shown in and 6, when the new energy vehicle is used in winter, the fan 9 and the electric heating tube 12 are controlled to start working through the external control panel, and the heat generated by the electric heating tube 12 is blown into the inside of the main body box 2 by the fan 9, and is surrounded by The air circulating in the main body box 2 brings heat to the periphery of the battery assembly 5 , thereby increasing the temperature of the air around the battery assembly 5 .

[0036] Working principle: when the battery pack 5 needs to be put into the main body box 2, manually pull the card slot 301 so that the L-shaped bracket 303 leaves the inner side of the card slot 301, and then manually open the two sets of L-shaped brackets 303 downwards , release the fixing effect on the cover plate 1, then open the cover plate 1, hold the handle on the battery assembly 5, and slowly put the battery assembly 5 into the inside of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com