Device and method for detecting slurry filling fullness in electromagnetic sleeve grouting construction stage

A sleeve grouting and construction stage technology, applied in the direction of measuring devices, material inspection products, analysis materials, etc., can solve problems such as inability to make up for grouting quality defects, and achieve the effect of ensuring quality controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

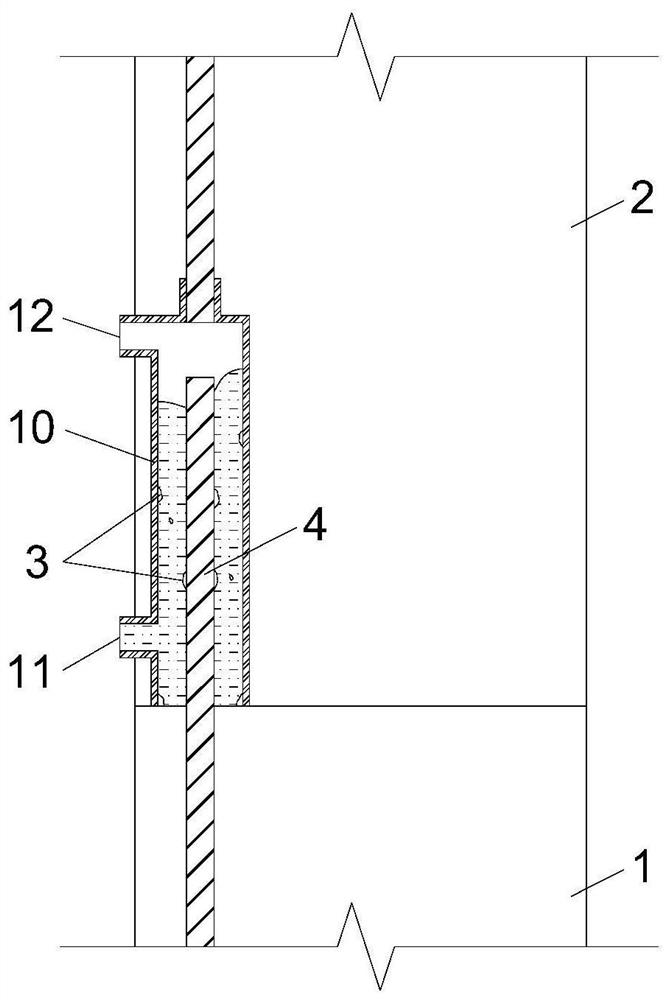

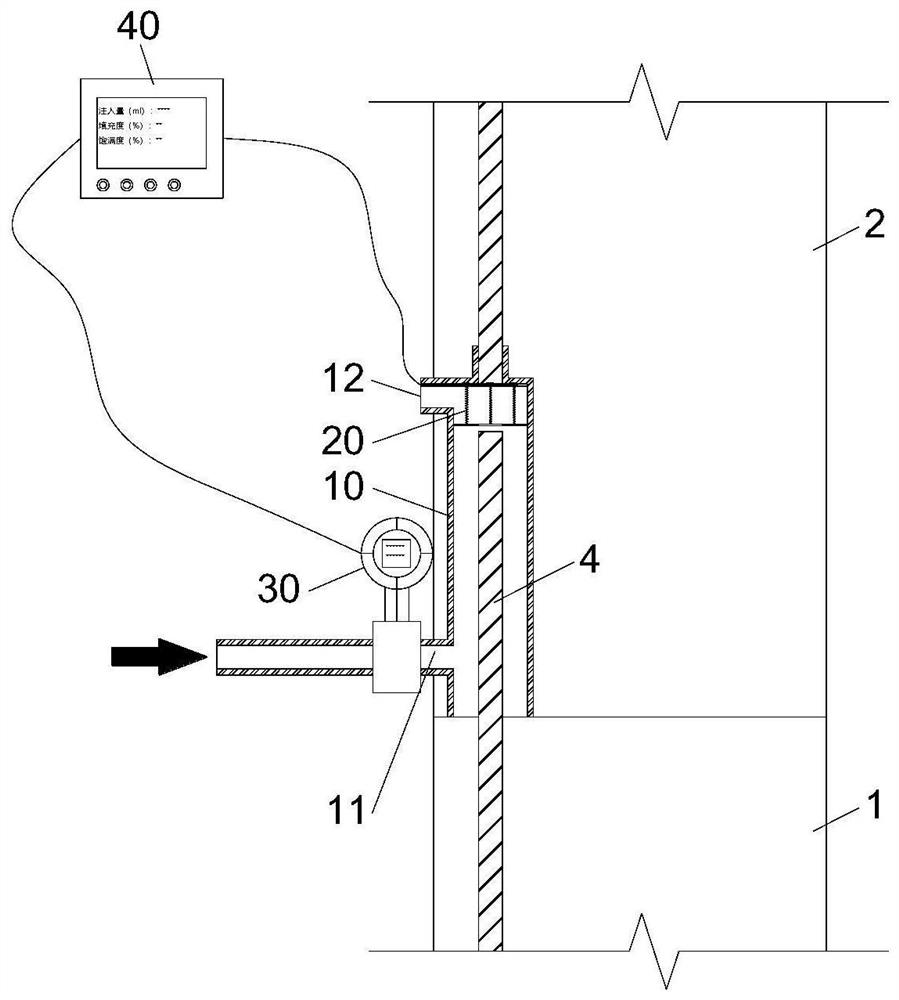

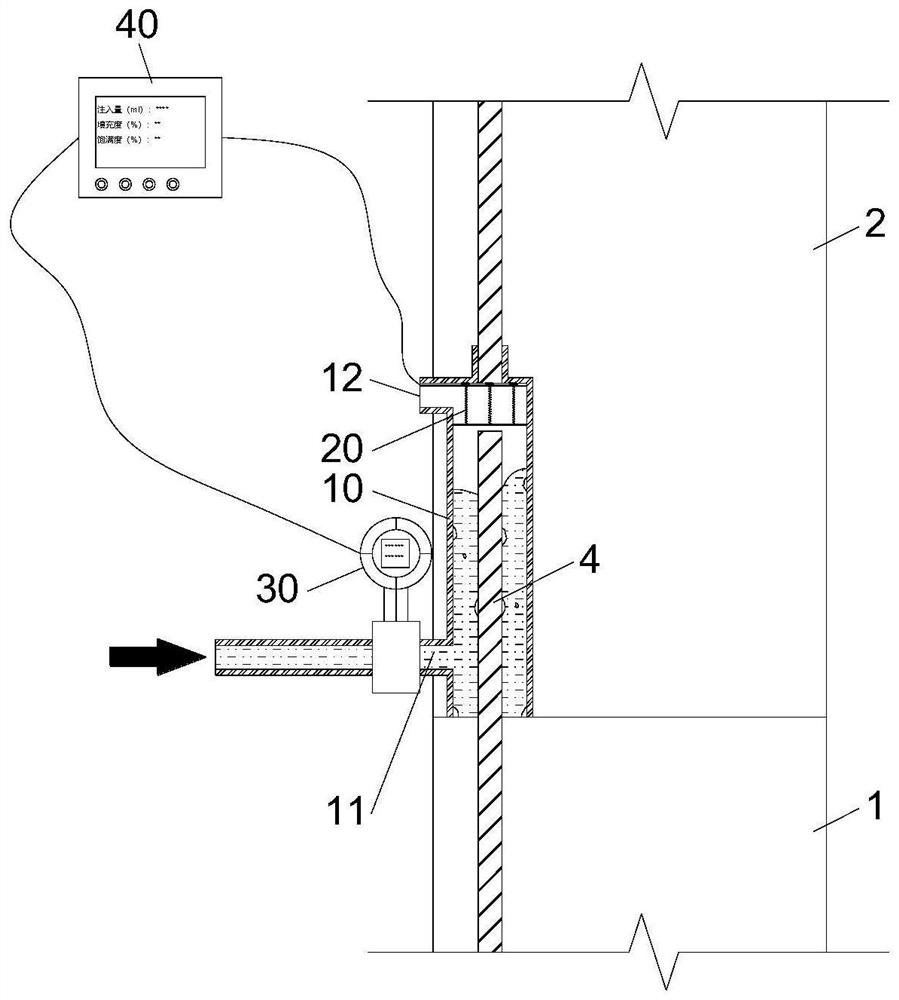

[0041] combine Figure 2 to Figure 5 Describe the electromagnetic sleeve grouting construction stage slurry filling fullness detection device of the present invention, it comprises:

[0042] The back pressure device 20 is arranged in the inner cavity of the sleeve 10 and coincides with the axis of the sleeve 10;

[0043] The data acquisition and analysis module 40 is connected with the back pressure device 20 for signal;

[0044] Wherein, the back pressure device 20 comprises a base 22, a back pressure piece 21 and a plurality of slide bars 24, the outer diameter of the base 22 and the back pressure piece 21 is adapted to the inner diameter of the sleeve 10, the base 22 and the back pressure piece 21 Up and down are arranged at intervals, and a plurality of slide bars 24 are evenly distributed between the base 22 and the counter pressure sheet 21 in the radial direction. The slide bar 24 is a sliding rheostat whose resistance is evenly distributed along its length. 22 is hin...

Embodiment 2

[0050] Different from Embodiment 1, the electromagnetic sleeve grouting construction stage slurry filling fullness detection device of the present invention also includes an electromagnetic flowmeter 30, and the electromagnetic flowmeter 30 is arranged on the grouting hole 11 connected to the sleeve 10. On the pipeline, and the electromagnetic flowmeter 30 is connected with the signal of the data acquisition and analysis module 40, which is used to monitor the injected slurry injection volume V in the sleeve 10 gin Send to the data collection and analysis module 40.

Embodiment 3

[0052] combine Figure 2 to Figure 5 The method for detecting the fullness of slurry filling in the construction stage of electromagnetic sleeve grouting of the present invention is described, and the specific steps are as follows:

[0053] S1: Pre-measure the actual inner cavity volume V after the sleeve 10 is inserted into the embedded steel bar 4 rc ;

[0054] S2: if figure 2 As shown, the upper and lower prefabricated components to be connected are assembled, respectively prefabricated component one 1 and prefabricated component two 2, and the back pressure device 20 is embedded in the inner cavity of the sleeve 10 of the prefabricated component two 2, and the prefabricated The pre-embedded steel bar 4 of component 1 is aligned with the installation position in the sleeve 10, and the electromagnetic flowmeter 30 is arranged on the grouting pipeline connected to the grout inlet 11 of the sleeve 10. The back pressure device 20 and the electromagnetic flowmeter 30 are resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com