Method for measuring metal material in waste circuit board

A technology of waste circuit boards and determination methods, which is applied in the direction of material excitation analysis, thermal excitation analysis, etc., can solve the problem of less exploration of simultaneous determination methods of multiple elements, achieve high sensitivity and avoid the effect of tin loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

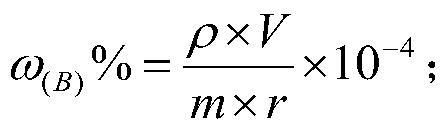

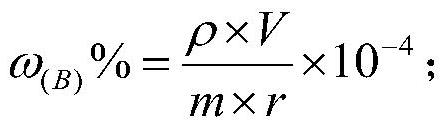

Method used

Image

Examples

Embodiment 1

[0027] (1) Sample pretreatment:

[0028] Preparation of tartaric acid solution (100g / L): Weigh 50g of tartaric acid and place it in a 500mL beaker, dissolve it in water, transfer it to a 500mL volumetric flask, dilute to the mark with water, mix well, and then place it in a reagent bottle;

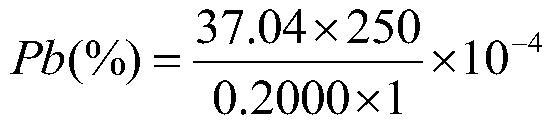

[0029] Weigh 0.2000g of the waste circuit board sample and place it in a 250mL conical beaker, moisten it with 1mL of deionized water, add 10mL of hydrochloric acid and 7.5mL of tartaric acid solution, cover with a watch glass, place it on an electric heating plate to heat, and dissolve at low temperature for about 5 minutes. Remove and cool, add 2mL hydrogen peroxide drop by drop, after the reaction is stable, put the triangular beaker on the electric heating plate and continue to dissolve at low temperature, repeat the above operation steps, repeatedly add hydrogen peroxide dropwise until the sample is completely dissolved, and dissolve at low temperature until it can dissolve If the flo...

Embodiment 2

[0047] (1) Sample pretreatment:

[0048] Weigh 0.3000g waste circuit board sample and place it in a 250mL conical beaker, wet it with 2mL deionized water, add 10mL hydrochloric acid and 7.5mL tartaric acid solution, cover with a watch glass, heat on an electric heating plate, dissolve at low temperature for 10min, take Cool down, add 2mL hydrogen peroxide drop by drop, after the reaction is stable, put the triangular beaker on the electric heating plate and continue to dissolve at low temperature, repeat the above operation steps, repeatedly add hydrogen peroxide dropwise until the sample is completely dissolved, and dissolve at low temperature until it can flow If the solution is less than 20mL, remove the conical beaker from the electric heating plate, add 30mL hydrochloric acid to dissolve the residue after cooling slightly, rinse the wall of the conical beaker with deionized water, put it back on the electric heating plate, until it boils slightly, and the residue Take off...

Embodiment 3

[0057] (1) Sample pretreatment:

[0058] Weigh 0.2500g waste circuit board sample into a 250mL conical beaker, moisten it with 1.5mL deionized water, add 10mL hydrochloric acid and 7.5mL tartaric acid solution, cover with a watch glass, heat on an electric heating plate, dissolve at low temperature for 8min, Remove and cool, add 1.5mL hydrogen peroxide drop by drop, after the reaction is stable, put the triangular beaker on the electric heating plate and continue to dissolve at low temperature, repeat the above operation steps, repeatedly add hydrogen peroxide dropwise until the sample is completely dissolved, and dissolve at low temperature to If the flowable solution is less than 20mL, remove the conical beaker from the electric heating plate, add 20mL hydrochloric acid to dissolve the residue after cooling slightly, rinse the wall of the conical beaker with deionized water, put it on the electric heating plate again, and bring it to a slight boil. Remove the triangular beak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com