Filling slurry low-resistance free-flow pipeline conveying system

A pipeline transportation and filling slurry technology, which is applied in the pipeline system, pipeline protection, pipeline damage/wear prevention, etc., can solve the problems of increasing local resistance, pipeline damage, pipe burst, etc., to avoid unevenness and reduce resistance along the way , reduce the effect of local resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

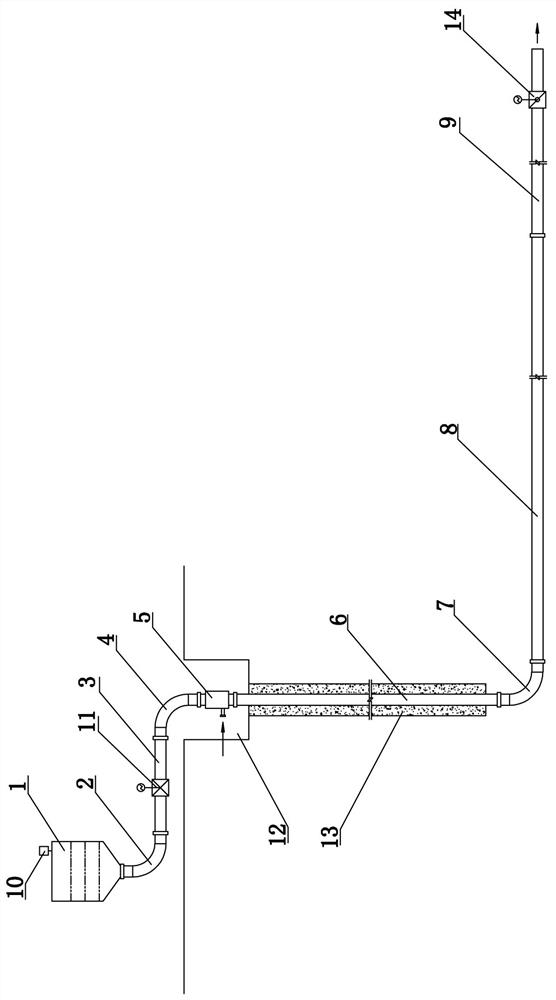

[0030] When starting to fill, when the liquid level of the slurry in the receiving hopper 1 reaches the discharge level, open the electric on-off valve 11; Position interlocking electric regulating valve 14, by adjusting the opening of the electric regulating valve 14, the liquid level of the filling slurry in the receiving hopper 1 is controlled between the set maximum liquid level and the minimum liquid level, so that the flow rate of the filling slurry in the receiving hopper 1 Balanced, the liquid level is maintained near the discharge liquid level to ensure that the filling slurry is in a state of siphon full pipe flow.

[0031] The filling vertical pipe 6 is a rigid pipeline, adopts 16Mn thick-walled steel pipe or bimetal wear-resistant steel pipe, is arranged in the filling borehole 13 outside the filling station, and is composed of multiple sections of steel pipes, the length of each section of steel pipe is 3 ~ 6m, Wear-resistant sealing rubber gaskets are arranged be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com