Air filter blowback spray head, system and cleaning method

A technology of air filter and reverse blow nozzle, applied in the direction of fuel air filter, chemical instrument and method, separation method, etc., can solve the problem of increasing operating cost and maintenance cost, failure, maintenance cost and cost increase, and reducing engine Power and other problems, to achieve the effect of reducing maintenance cycle and labor intensity, reducing maintenance labor intensity, and reducing comprehensive air intake resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

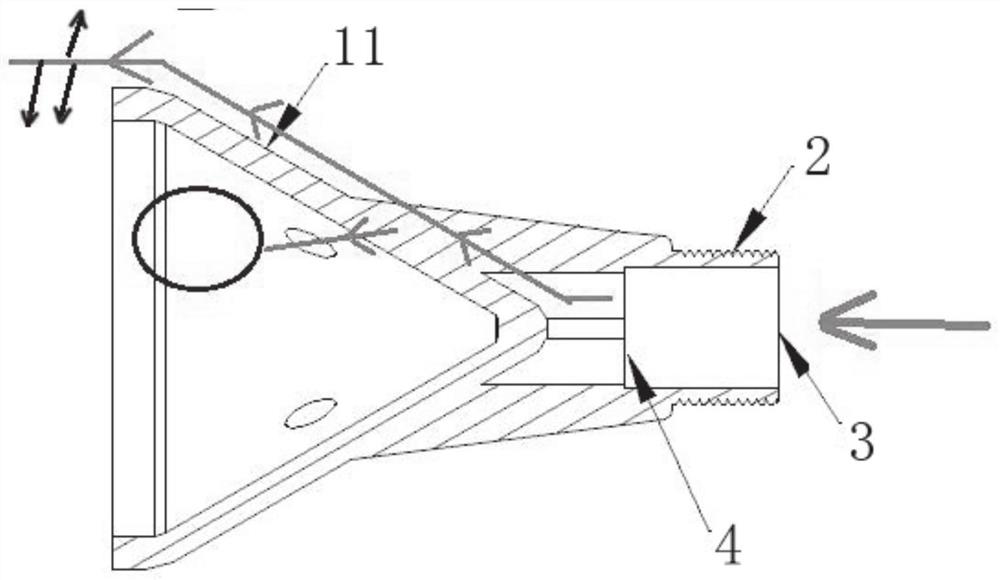

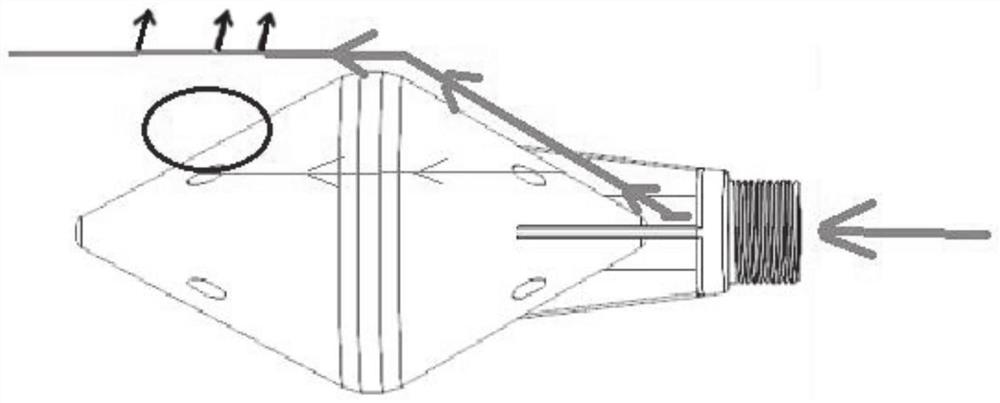

[0046] This embodiment provides an air filter blowback nozzle, such as figure 1 As shown, according to the flow direction of the reverse blowing airflow, it passes through the air inlet 3, the air outlet 4, and the conical deflector 11 in turn. The gas guiding device of the reverse blowing nozzle is composed of two conical deflectors 11 with opposite openings. The included angle formed by the flow guide shell at the cut section of the tapered flow guide along the axis may be 20 degrees to 120 degrees, preferably 65 degrees. More preferably, such as figure 1 As shown, the gas guide device is a rhombus shroud when the shaft section is rhombus.

Embodiment 2

[0048] This embodiment provides an air filter blowback nozzle system, such as Figure 8 As shown, the blowback nozzle installation device in Embodiment 1 is installed on the air filter housing connection interface 10, and the air filter housing connection interface 10 is connected to the air inlet pipe 9. The blowback gas enters the air filter through the inlet pipe 9, the connection interface 10, and the blowback nozzle 1. Under the action of the blowback nozzle 1, the gas follows the cone of the gas guide device and enters the filter element 16 in an enlarged cylindrical airflow. In the cavity, an aerodynamic turbulence is formed in the secondary air inlet chamber 15 to shake off the dust on the outer surface of the filter element 16, and a uniform air column and pressure field are formed to avoid local abnormal pressure and air flow, resulting in the 16 part of the filter element The damage of the area reduces the life of the filter element 16. Therefore, the axis of the gas...

Embodiment 3

[0051] This embodiment provides an air filter blowback nozzle system, such as Picture 9 As shown, the blowback nozzle installation device in Embodiment 1 is installed on the air filter housing connection interface 10, and the air filter housing connection interface 10 is connected to the connecting air pipe 27. The blowback gas enters the air filter through the connecting gas pipe 27, the connection interface 10, and the blowback nozzle 1. Under the action of the blowback nozzle 1, the gas enters the filter element 16 in an enlarged cylindrical airflow along the rhombus flow cover of the gas guide device. In the inner cavity of the secondary air inlet chamber 15, aerodynamic turbulence is formed in the secondary air inlet chamber 15 to shake off the dust on the outer surface of the filter element 16, and a uniform air column and pressure field are formed to avoid local abnormal pressure and air flow, which may cause the filter element The damage of the 16 part of the area redu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com