Ceramic tile attaching method and spacer

A ceramic tile and sticking technology, applied in covering/lining, construction, building structure, etc., can solve problems such as breakage and increase processes, and achieve the effect of reducing weight, ensuring sticking effect, and increasing wetting and bonding ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A method for attaching ceramic tiles, which is characterized in that it comprises the following steps: 1) According to the different sizes of tiles to be attached, a number of gasket attachment positions are determined on the main body of the building; 2) Each gasket is fixed to the building by anchor bolts Corresponding position of the main body; 3) Put structural glue on the gasket, and then glue the ceramic tile and the gasket together.

[0042] Wherein, the gasket is a metal gasket, including one or more of iron sheet, aluminum sheet, and stainless steel sheet. The specifications of the gasket include 50*50mm, 80*80mm, 100*100mm and so on. The structural glue is epoxy resin AB glue. The ceramic tiles are ceramic tiles or stone materials. In this embodiment, the gasket is preferably an aluminum alloy gasket, which is light in weight.

[0043] Compared with the prior art, the tile attachment method provided by this embodiment is to fix the gasket on the main body of the...

Embodiment 2

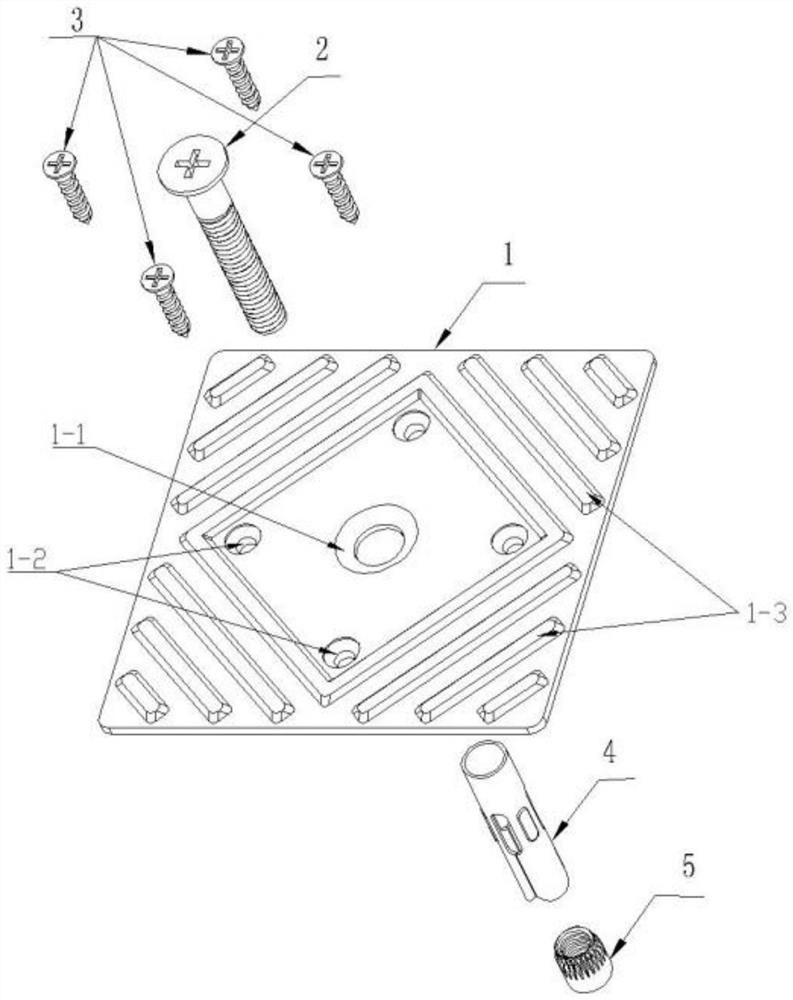

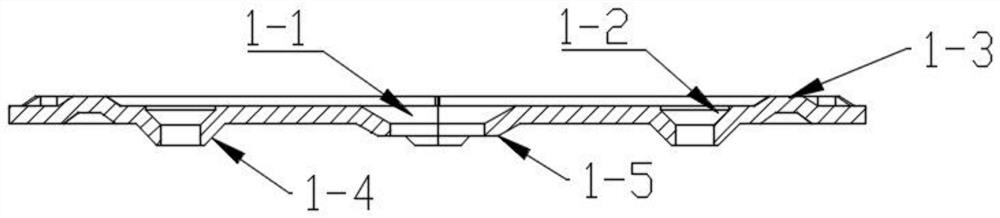

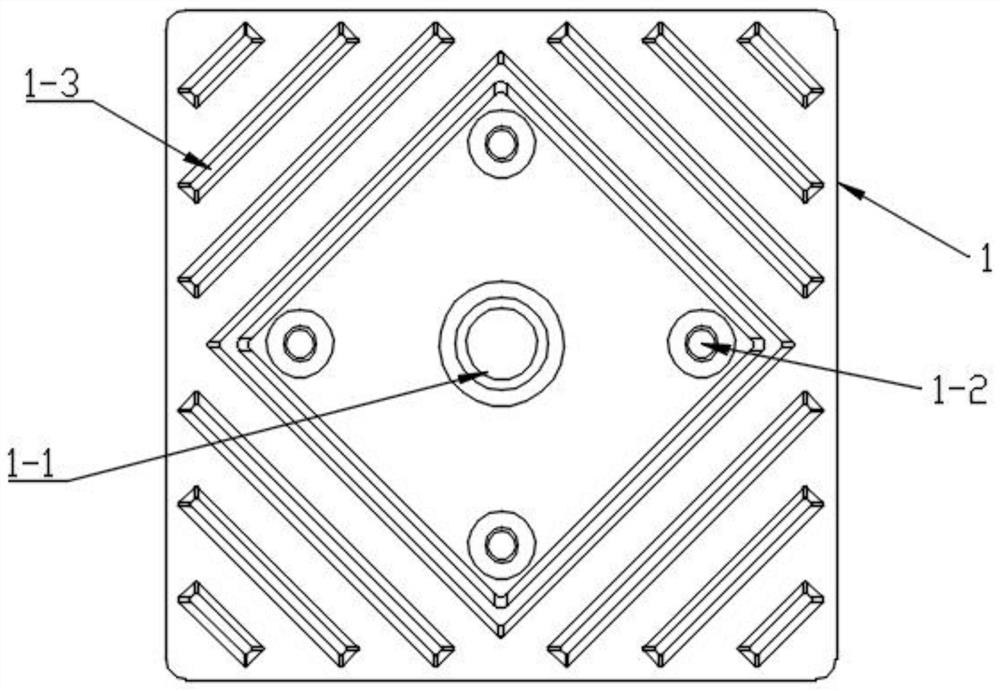

[0047] Such as figure 1 , figure 2 As shown, a ceramic tile attachment gasket is used to connect a ceramic tile and a building body, comprising: a gasket body 1 and anchor bolts 2, where the anchor bolts 2 are used to fix the gasket body 1 on the building body, A number of raised structures or recessed structures are provided on the ceramic tile connecting surface of the gasket body 1, and the adjacent raised structures or the recessed structures form a containing groove for accommodating the adhesive. The top surface of the convex structure or the concave structure is flush. In this way, not only the flatness of the installation is ensured, but also when the tile is attached and pressed, the coated glue will be squeezed and left in the accommodating groove, which effectively improves the adhesion between the tile and the gasket and ensures the attachment effect.

[0048] In the actual design, the specifications of the gaskets are various. The gaskets have specifications of 50*5...

Embodiment 3

[0057] Such as Image 6 As shown, a ceramic tile attachment gasket whose structure is basically the same as that of the second embodiment; the difference between the ceramic tile attachment gasket provided in this embodiment and the second embodiment is that the ceramic tile of the gasket body 1 is connected A roughened structure 6 is provided on the surface of the surface or in the recessed structure. The roughened structure 6 covers the surface of the gasket body or the recessed structure. The roughened structure increases the wetting and bonding ability of the glue, so that the glue is better attached, effectively improving the adhesion between the tile and the gasket, and ensuring the adhesion effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com