Mobile working machine with pivotable cab

A technology of working machines and cabs, which is applied in the field of mobile working machines, can solve problems and time-consuming problems, and achieve the effects of saving space, simplifying laying down, and improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

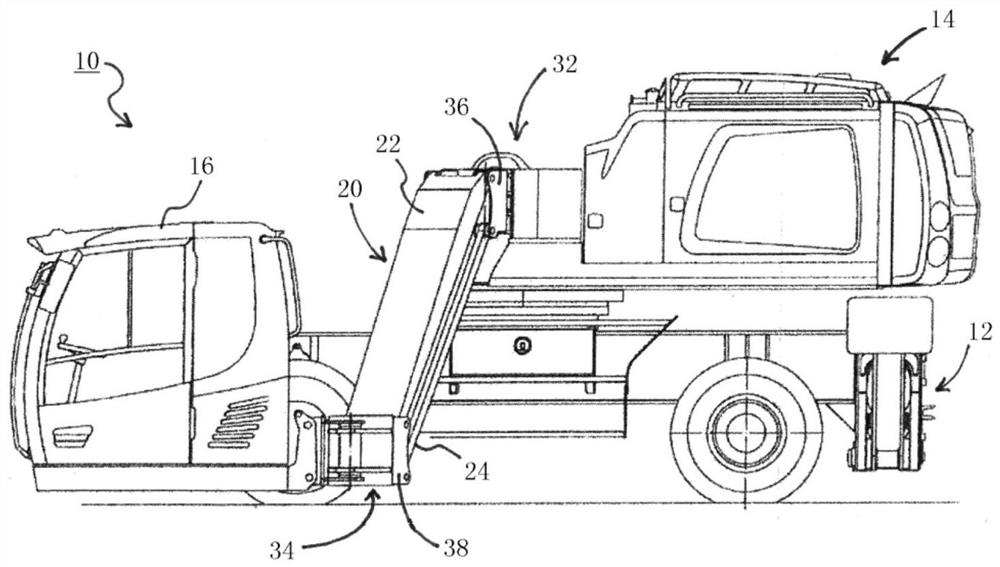

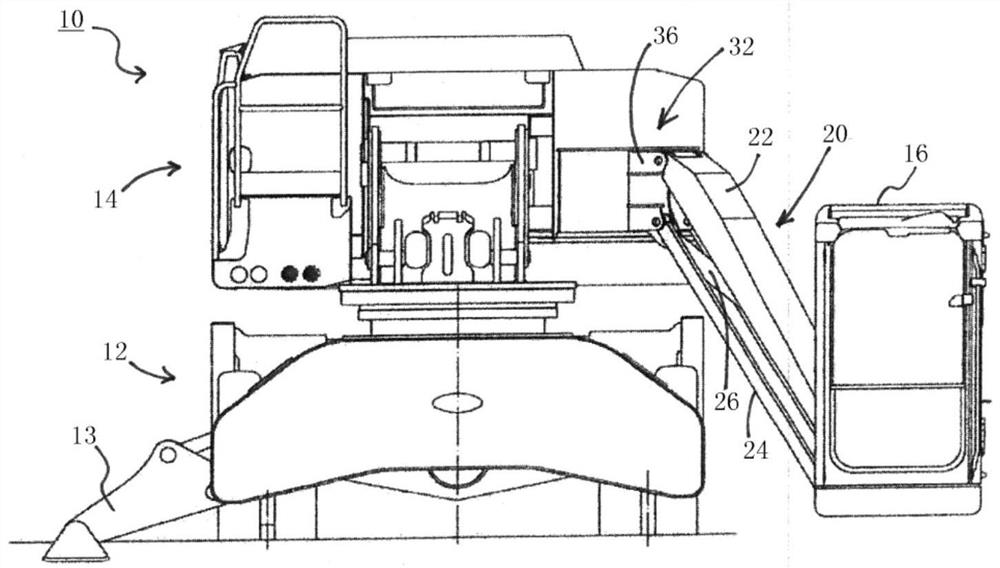

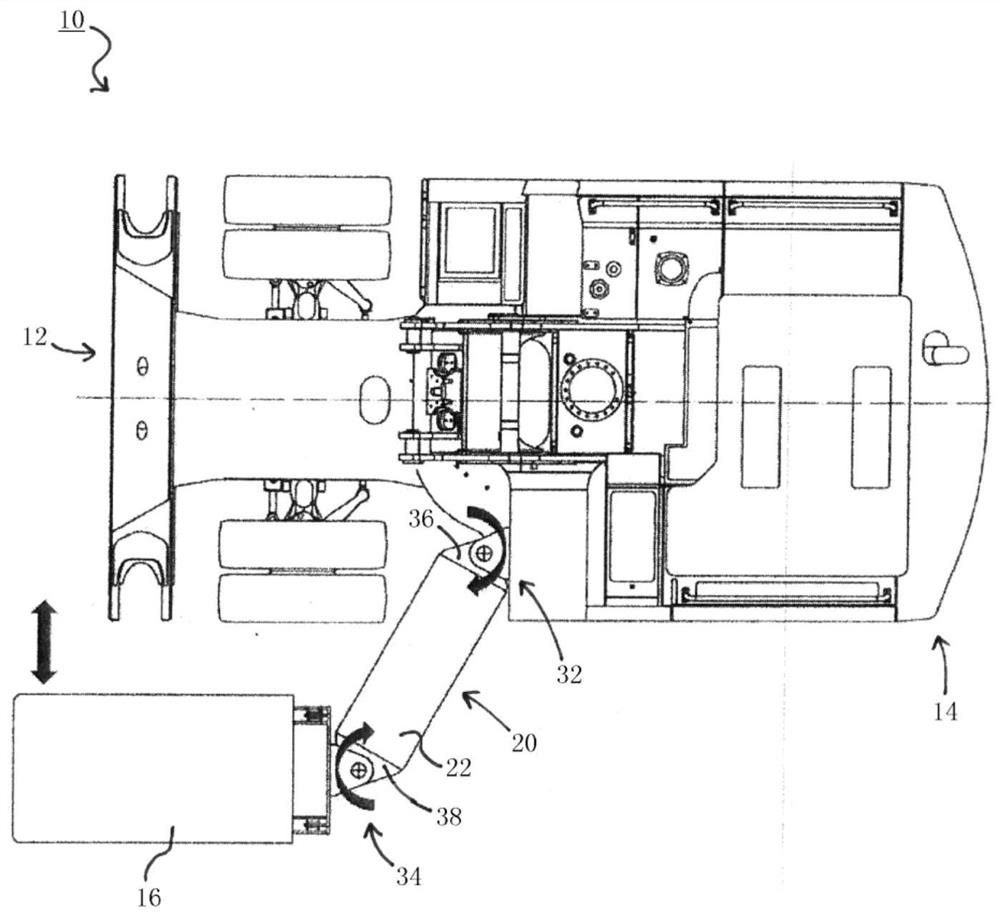

[0032] exist figure 1 A side view of one embodiment of a mobile work machine 10 according to the present invention is shown in , while figure 2 A front view of the work machine 10 is shown and image 3 A top view is shown. The work machine 10 comprises a travelable, ie including running gear, undercarriage 12 having a plurality of foldable supports 13 on which a superstructure 14 is rotatably supported. A boom, not shown further here, can be articulated at the superstructure 14 and can be pivoted about a horizontal axis. In general, a working machine according to the invention can be, for example, a material handling device or an earth-moving device such as an excavator, in particular a hydraulic excavator.

[0033] Work machine 10 may be controlled by an operator from cab 16 . The cab 16 is not directly connected to the superstructure but is connected via a lifting device. The lifting device comprises a lifting arm 20 which is connected to the superstructure 14 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com