Textile fabric processing equipment

A technology for processing equipment and textile fabrics, applied in the field of textile fabric processing equipment, can solve the problems of low processing efficiency, affecting the actual quality of fabrics, and concentration of artificially configured mixtures, so as to improve functionality and practicability, and improve convenience and practicality performance and improve processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

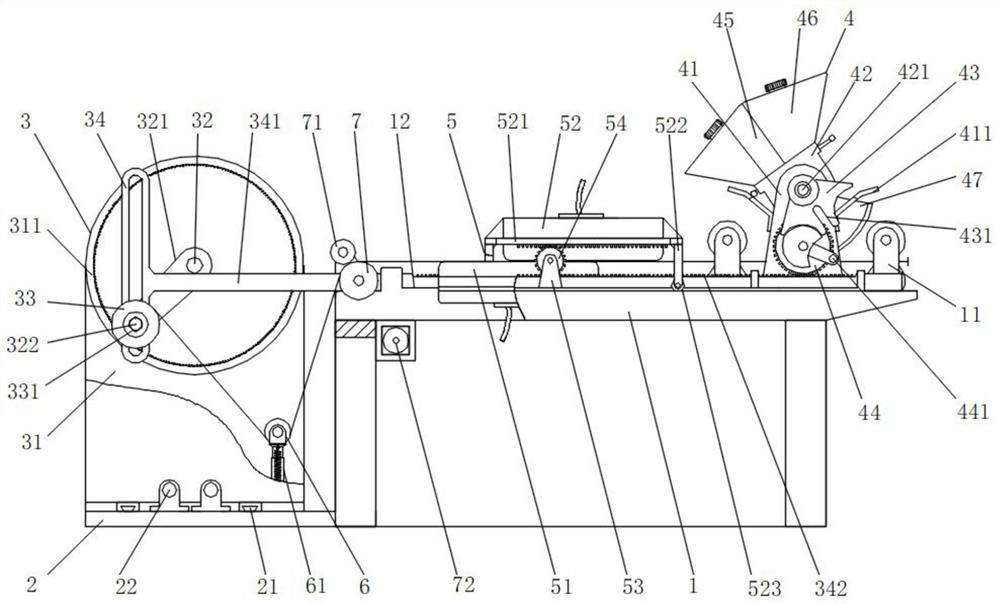

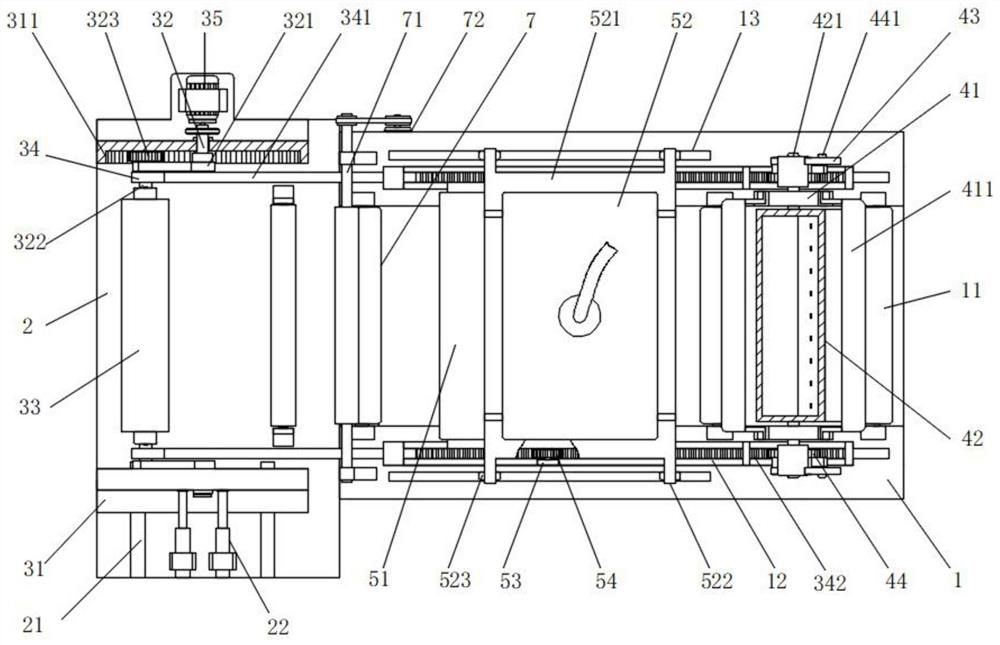

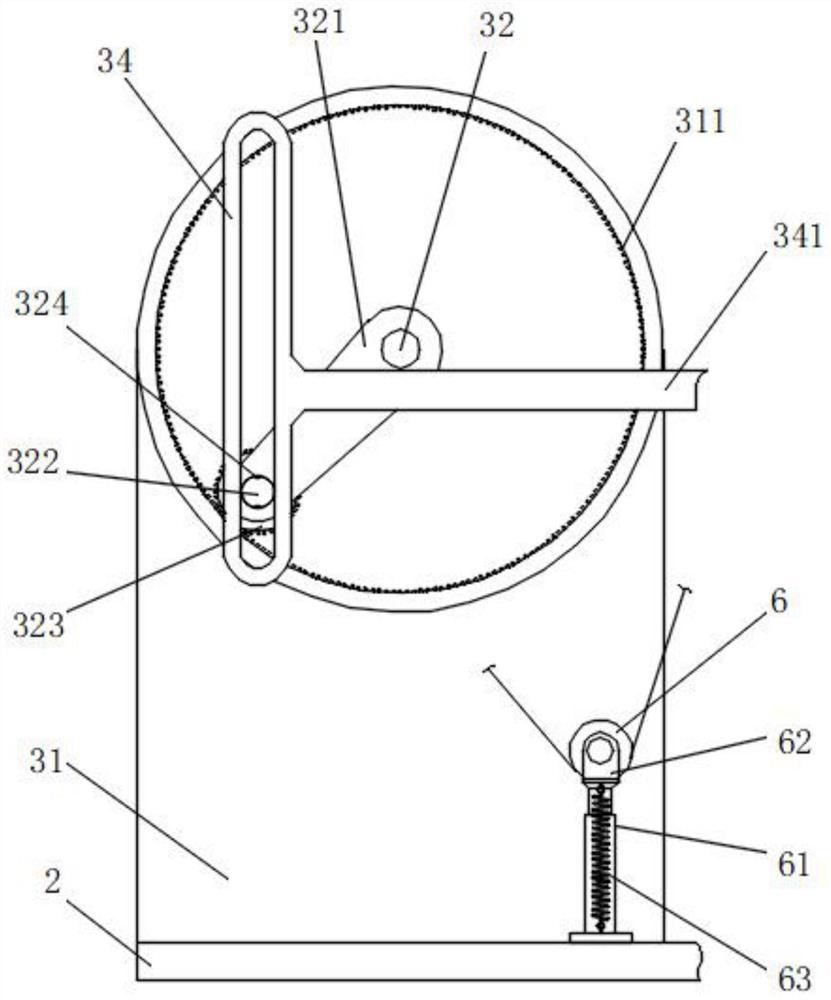

[0038] The specific embodiment is as follows: by slidingly connecting one of the support plates 31 to the top of the bottom plate 2, and then controlling the outward movement of one of the support plates 31 through the hydraulic rod 22, the two support plates 31 can be driven away from each other, and the cloth rolling roller 33 is provided with an insertion hole 331 to engage with the two retracting card shafts 322, and the engagement of the fixed key and the keyway 324 is used to realize the circumferential fixation of the cloth rolling roller 33, and then after the two support plates 31 are separated, , the cloth rolling roller 33 can be removed, and the two ends of the insertion hole 331 of the new cloth rolling roller 33 can also be inserted into the two retracting card shafts 322, and the hydraulic rod 22 is driven to push the support plate 31 to move inwards to realize alignment. The fixing of the cloth roll 33 can continue new processing, thereby greatly facilitating th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com