Oily sludge treatment system based on three-section rotary kiln

A technology of sludge treatment and rotary kiln, which is applied in the fields of pyrolysis treatment of sludge, petroleum industry, special form of dry distillation, etc. It can solve the problems of sticky wall scaling, unstable products, insufficient reaction, etc., and achieve a controllable output Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

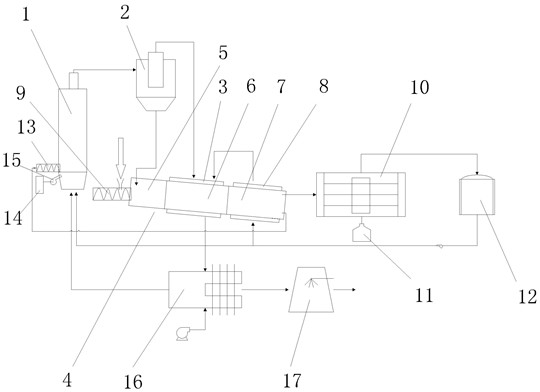

[0020] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings. Such as figure 1 Shown: an oily sludge treatment system based on a three-stage rotary kiln, which includes a fluidized bed 1, the outlet end of the fluidized bed 1 is connected to a cyclone separator 2 through a flue, and the cyclone separator 2 The gas outlet end of the cyclone separator is connected with the inner cavity of the heat transfer jacket 3 through a pipeline, while the ash discharge end of the cyclone separator 2 is connected with the inlet end of the three-stage rotary kiln 4 through a pipeline, and the three-stage rotary kiln 4 is sequentially divided into mixing section 5, heat transfer section 6 and combustion section 7 from the inlet end to the outlet end, the heat transfer jacket 3 is arranged outside the heat transfer section 6, and a Combustion jacket 8, the three-stage rotary kiln 4 is also provided with a feeding screw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com