Rubber modified asphalt preparation device

A preparation device and rubber modification technology, which is applied in building components, building insulation materials, construction, etc., can solve the problems of poor quality of TerminalBlend rubber modified asphalt, thermo-oxidative aging reaction of asphalt, etc., so as to avoid adverse effects and ensure normal operation running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

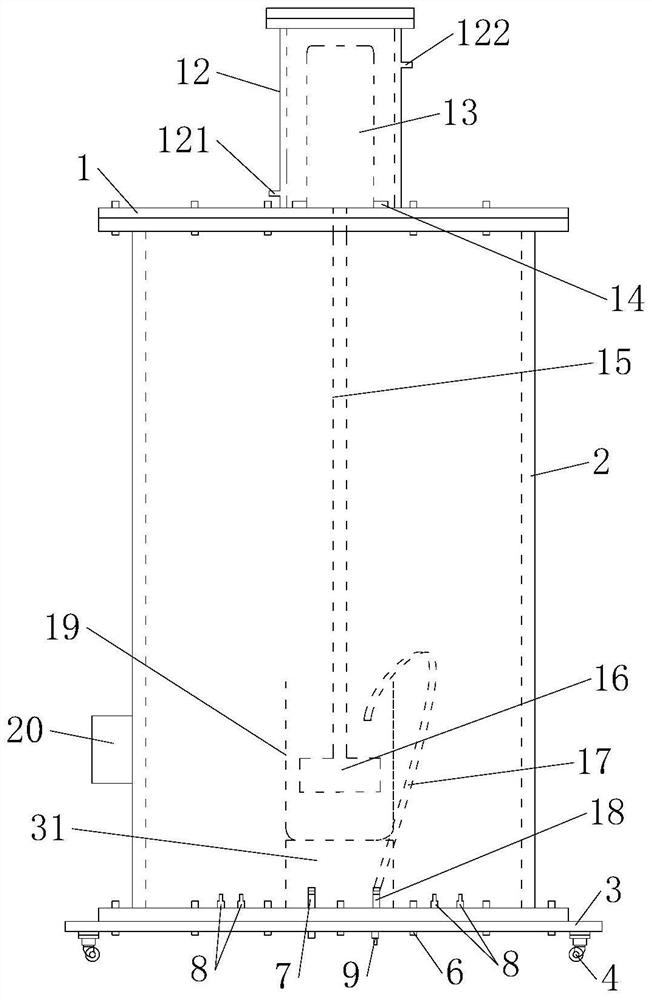

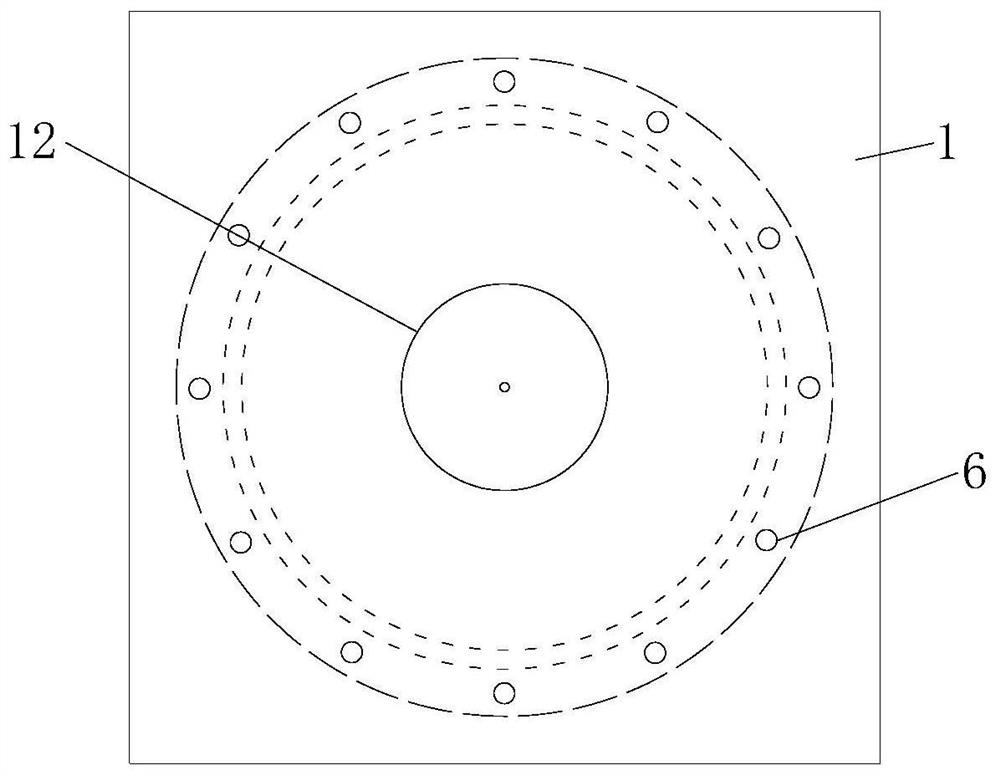

[0050] This embodiment provides a rubber modified asphalt preparation device, see Figure 1-2 , including a tank body, the tank body includes a tank body side wall 2 and a top cover 1 and a bottom plate 3 that are respectively sealed and connected to the two ends of the tank body side wall 2, the tank body is provided with a connecting joint, and the tank body is provided with Heating equipment 31 is arranged, and described heating equipment 31 is used for heating the rubber-asphalt mixture inside described tank body, and described tank body is provided with motor 13, and the outside of described motor 13 is provided with motor sealing compartment 12, and described motor sealing compartment 12 is in sealing connection with the tank body, the motor 13 is connected with a stirring shaft 15, and the stirring shaft 15 passes through the tank body and is connected with a dispersing and emulsifying head 16, and the dispersing and emulsifying head 16 is used for shearing the rubber a...

Embodiment 2

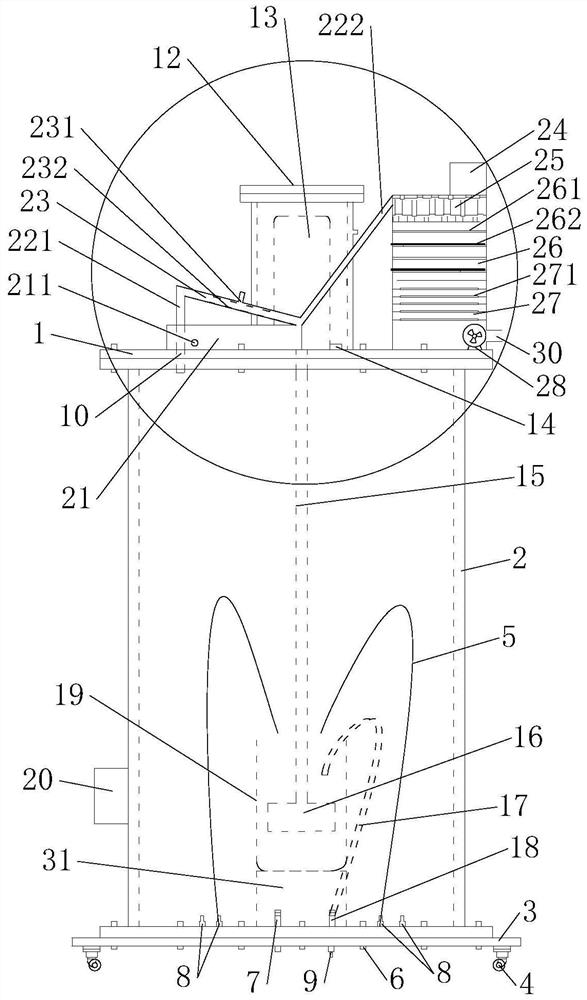

[0057] This embodiment provides a rubber modified asphalt preparation device, see Figure 3-5 , which is different from the rubber-modified asphalt preparation device described in Example 1 in that the tank body is provided with an exhaust channel 10, and the exhaust channel 10 is used to discharge the gas inside the tank body. In this example, if image 3 As shown, the exhaust passage 10 is arranged on the top cover 1, and the exhaust passage 10 is provided with a flue gas treatment device, which is used to clean the toxic gas generated during the reaction of the rubber asphalt mixture. Harmful asphalt fumes. The asphalt fume contains high-molecular ring carbon hydrocarbon oily organic matter, dust, and strong carcinogens such as 3,4-benzopyrene, which are extremely harmful to the human body, so that when preparing Terminal Blend rubber-modified asphalt in the laboratory , the asphalt fumes produced are likely to cause injury to experimenters. The flue gas treatment device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com