Tristyrylphenol polyoxyethylene ether sulfonate and pesticide suspension concentrate

A technology of polyoxyethylene ether sulfonate and triphenylethylphenol, which is applied in biocides, animal repellents, plant growth regulators, etc., can solve the problem of poor dispersion performance, insufficient performance, and layered structure of pesticide suspensions. It can solve the problems of bottom and other problems, and achieve the effects of excellent anionic and non-ionic performance, improved utilization rate, good emulsification and dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

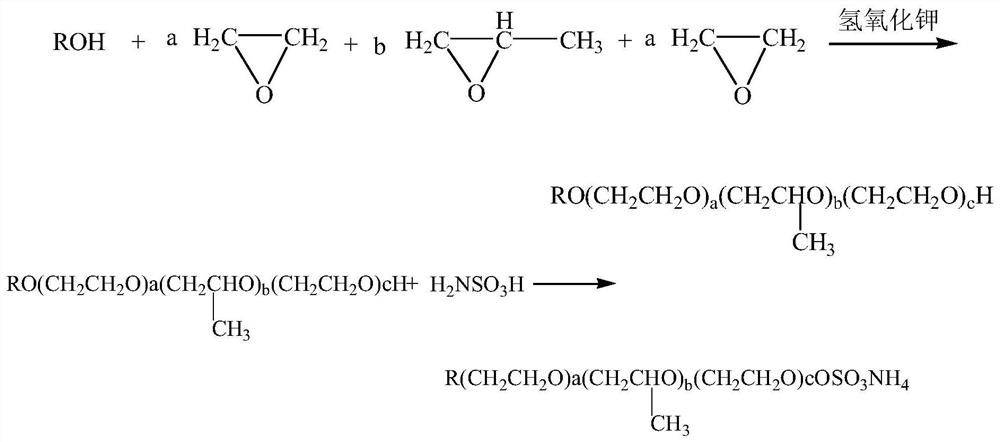

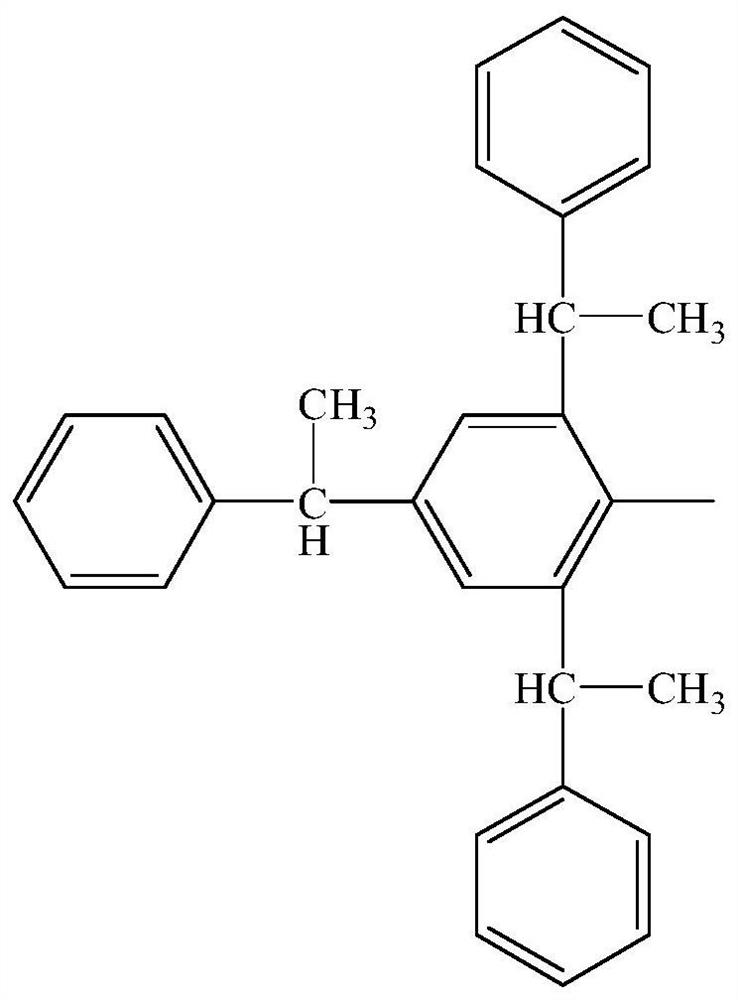

[0034] The preparation method of described tristyrylphenol polyoxyethylene ether sulfonate comprises the following steps:

[0035] (1) Add potassium hydroxide to triphenylethylphenol, vacuum treatment at 130-140°C for 1-2h, raise the temperature to 150-160°C, and continuously add ethylene oxide under the pressure of 0.25-0.3MPa, and the feeding is finished Then continue the aging reaction until the pressure in the system is negative pressure and the pressure is no longer reduced, and the reactant is obtained. (2) The reactant is cooled to 110-130°C, and propylene oxide is continuously added under the pressure of 0.25-0.3MPa, and then After the material is finished, continue the aging reaction until the pressure in the system is negative pressure and the pressure is no longer reduced, and the secondary reactant is obtained. (3) The temperature of the secondary reactant is raised to 150-160 ° C, and the pressure is continued under the pressure of 0.25-0.3MPa. Add ethylene oxide,...

Embodiment 1

[0042] (1) Add 0.4 potassium hydroxide to 406 triphenylethylphenol, vacuum treatment at 130°C for 1 hour, heat up to 160°C, and continuously add 220g of ethylene oxide under a pressure of 0.25MPa, and continue the aging reaction after the feeding is completed, Until the pressure in the system is a negative pressure and the pressure is no longer reduced, the reactant is obtained. (2) The reactant is cooled to 120°C, and 580g of propylene oxide is continuously added under a pressure of 0.3MPa. After the feeding is completed, the aging reaction is continued until The pressure in the system is a negative pressure and the pressure is no longer reduced, and the secondary reactant is obtained. (3) The temperature of the secondary reactant is raised to 160°C, and 220g of ethylene oxide is continuously added under a pressure of 0.25MPa. After the feeding is completed, continue Aging reaction, until the pressure in the system is negative pressure and the pressure no longer decreases, coo...

Embodiment 2

[0044] (1) Add 0.4g of potassium hydroxide to 406g of triphenylethylphenol, vacuum treatment at 130°C for 1.5h, heat up to 160°C, and continue to add 330g of ethylene oxide under a pressure of 0.25MPa, and continue to age after feeding Reaction, until the pressure in the system is negative pressure and the pressure is no longer reduced, the reactant is obtained, (2) the product is cooled to 120°C, and 290g of propylene oxide is continuously added under the pressure of 0.3MPa, and the aging reaction is continued after the feeding is completed. Until the pressure in the system is negative pressure and the pressure is no longer reduced, the secondary reactant is obtained. (3) The temperature of the secondary reactant is raised to 160 ° C, and 330 g of ethylene oxide is continuously added under a pressure of 0.25 MPa. Continue the aging reaction until the pressure in the system is negative pressure and the pressure does not decrease any more, cool down to obtain the product, (4) ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com