Preparation method of solid polycarboxylate superplasticizer

A technology of polycarboxylic acid and water reducing agent, applied in the field of building admixtures, can solve the problems of complex preparation process and high energy consumption, and achieve a simple and efficient synthesis process, low production cost and energy consumption, good fluidity and retention ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

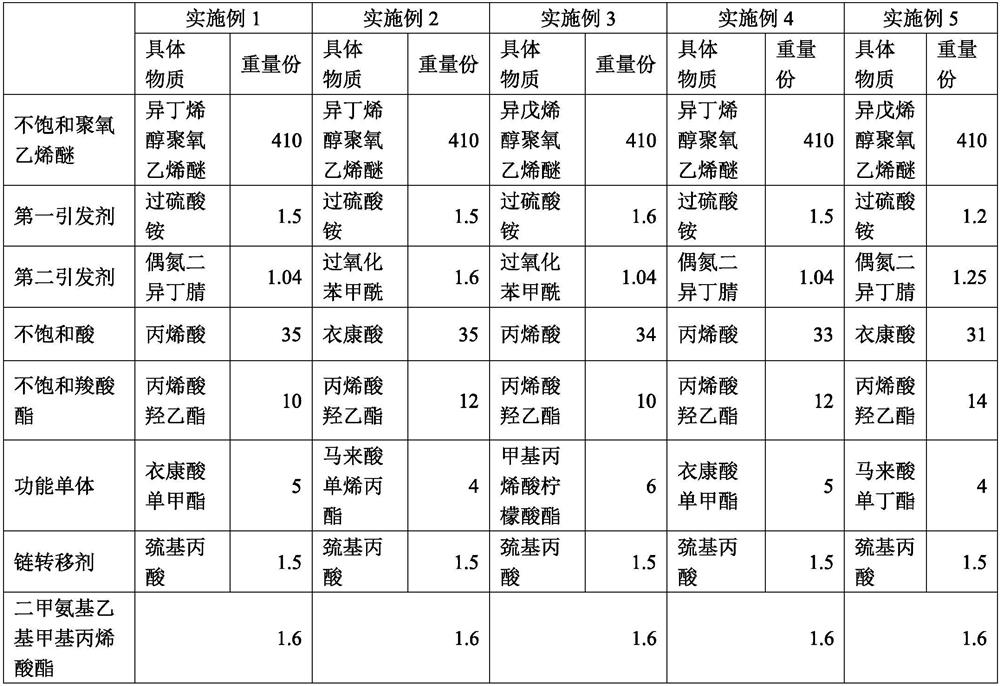

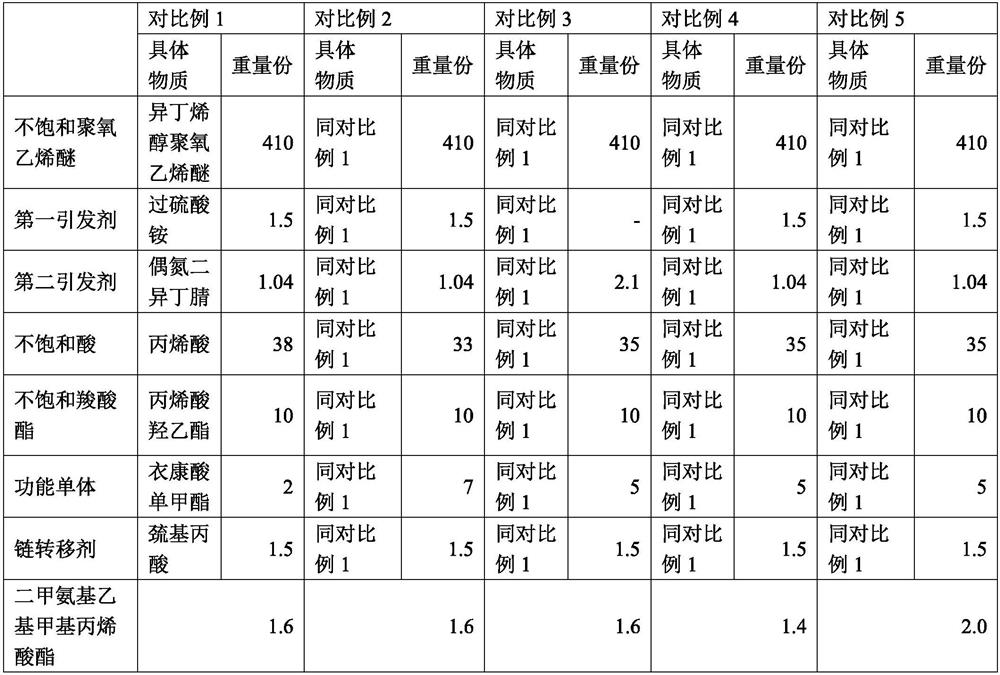

[0032] Each raw material component of embodiment 1 to 5 and consumption thereof are as shown in table 1:

[0033] Table 1

[0034]

[0035] Wherein, the number average molecular weight of the unsaturated polyoxyethylene ether is 2400, and the specific preparation method comprises the following steps:

[0036] (1) Add unsaturated polyoxyethylene ether into the reaction device, and heat until completely melted;

[0037] (2) Under heat preservation conditions, after adding 1 / 3 of the first mixture to the material obtained in step (1) and stirring evenly, add the first initiator and 1 / 4 of the second initiator at one time, stir for 2-3min, and then Add the second mixture dropwise to the reactor respectively;

[0038] After dropping 1 / 4 of the time, put 1 / 4 of the second initiator at one time;

[0039] After dropping 2 / 4 of the time, throw in 1 / 4 of the second initiator at one time;

[0040] After dropping 3 / 4 of the time, throw in the remaining 1 / 4 of the second initiator a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com