Composite material for packing box to present filled suspension images and texts and manufacturing method thereof

A composite material and manufacturing method technology, applied in the directions of printing device, printing, lining/interior coating, etc., can solve the problems of uneven surface of wooden packaging boxes, inability to improve the high quality of packaging boxes, poor consumer experience, etc. Natural aesthetics, improving consumer experience, and saving the effect of solid wood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Please refer to figure 1 , the figure shows a schematic diagram of the cross-sectional structure of a composite material used for packaging boxes to present filled suspended graphics and texts. Embodiment 1 of the present invention provides a composite material used for packaging boxes to present filled suspended graphics and texts. Including a substrate layer 1, the substrate layer 1 is any one of multi-layer plywood, medium density fiberboard, high density fiberboard, wood-plastic board, bamboo plywood, particle board, solid wood board or wood core board, the substrate layer 1 The dimensions are: 300-400mm in length, 200-250mm in width, and 4-8mm in thickness, preferably 350mm in length, 200mm in width, and 4mm in thickness in the first embodiment.

[0031] The surface of the substrate layer 1 is sprayed or pasted with a texture pattern layer 2, and the texture pattern layer 2 pasted on the surface of the substrate layer 1 is veneer paper or wood grain paper with wood...

Embodiment 2

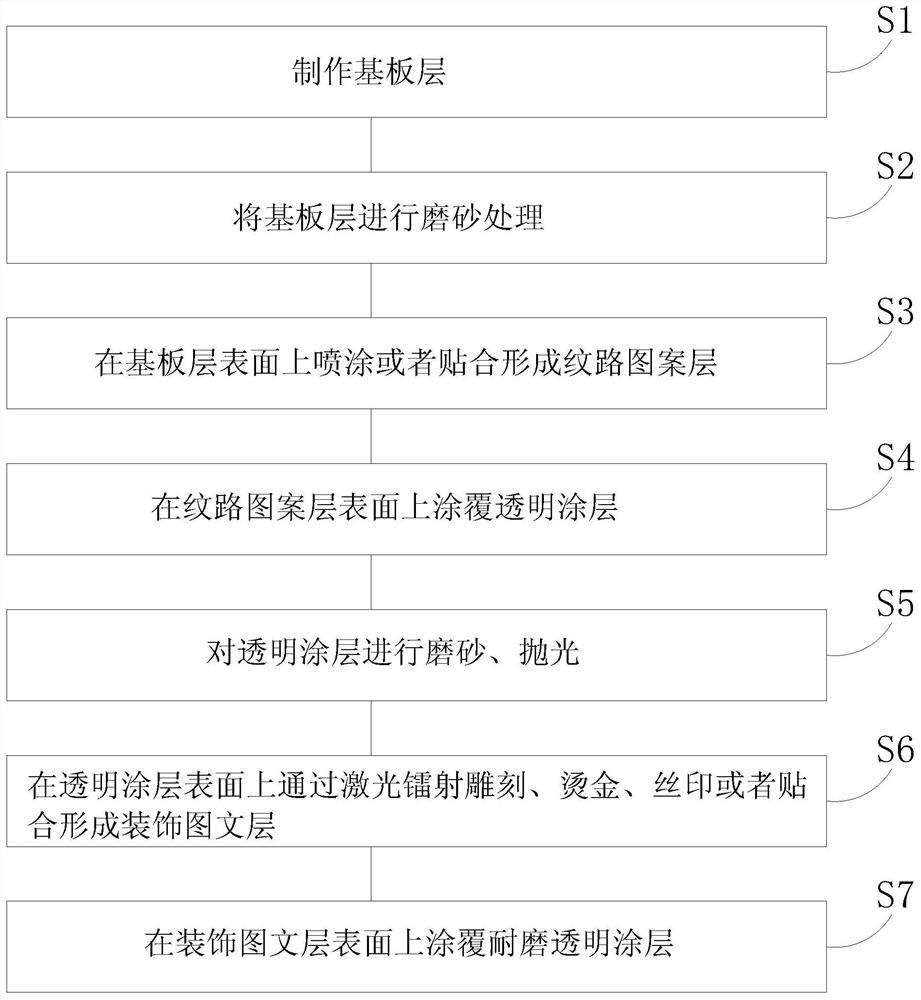

[0034] Please refer to figure 2 ,exist figure 2 shows a schematic diagram of the steps of a manufacturing method for a composite material for a packaging box that presents filled floating graphics and text. Embodiment 2 of the present invention provides a manufacturing method for a composite material that is used for a packaging box that displays filled floating graphics and text. The method is characterized in that it comprises the following steps:

[0035] Step S1 , fabricating the substrate layer 1 .

[0036] Substrate layer 1 can select wood core board for use, such as solid woods such as Chinese fir, poplar, paulownia, pine are made the wood strip of different specifications (such as long 300-400mm, wide 200-250mm, thick 4-8mm), the wood strip is used E0 grade environmentally friendly glue is assembled into boards as the substrate layer 1, and the substrate layer 1 is subjected to post-forming processing such as edge trimming, slotting, drilling, and concave surface m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com