A rebar grinding device with cooling water recovery function

A technology of rebar and cooling water, applied in the field of rebar, can solve the problems of danger, water source pollution, many equipment, etc., to achieve the effect of convenient operation, avoid hoarding, and speed up the flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

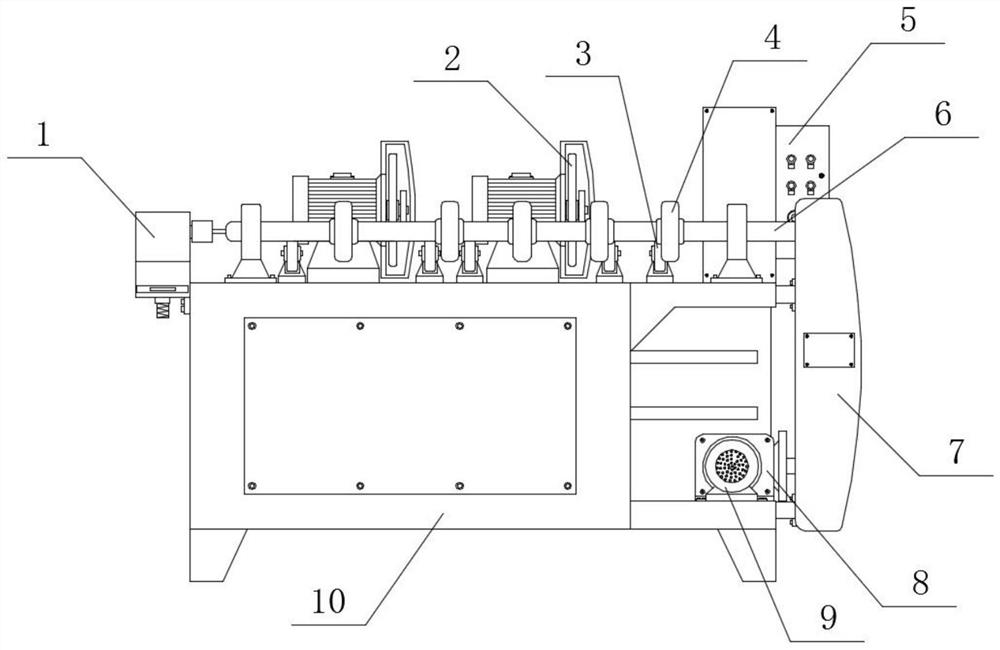

[0030] Such as figure 1 As shown, a rebar grinding device with cooling water recovery function includes a fixed workbench 10 and a motor 9. The front end of the fixed workbench 10 is connected to the right side of the front end face with a motor 9 through a screw, and the rear end face of the motor 9 is plugged into the Connected to the front end of the reducer 8, the right end of the reducer 8 is plugged into the inner side of the left end of the transmission box 7, and the upper position of the inner surface of the transmission box 7 is connected with a transmission rod 6 through a screw. The right side of the outer surface is sleeved with a rotating wheel 4, the rear of the rotating wheel 4 is provided with a control box 5 at the position on the right side of the top end face of the fixed workbench 10, and the left side of the control box 5 is provided with a guide wheel 3, and the guide wheel 3 The left side of the polishing machine 2 is provided with a polishing machine 2...

Embodiment 2

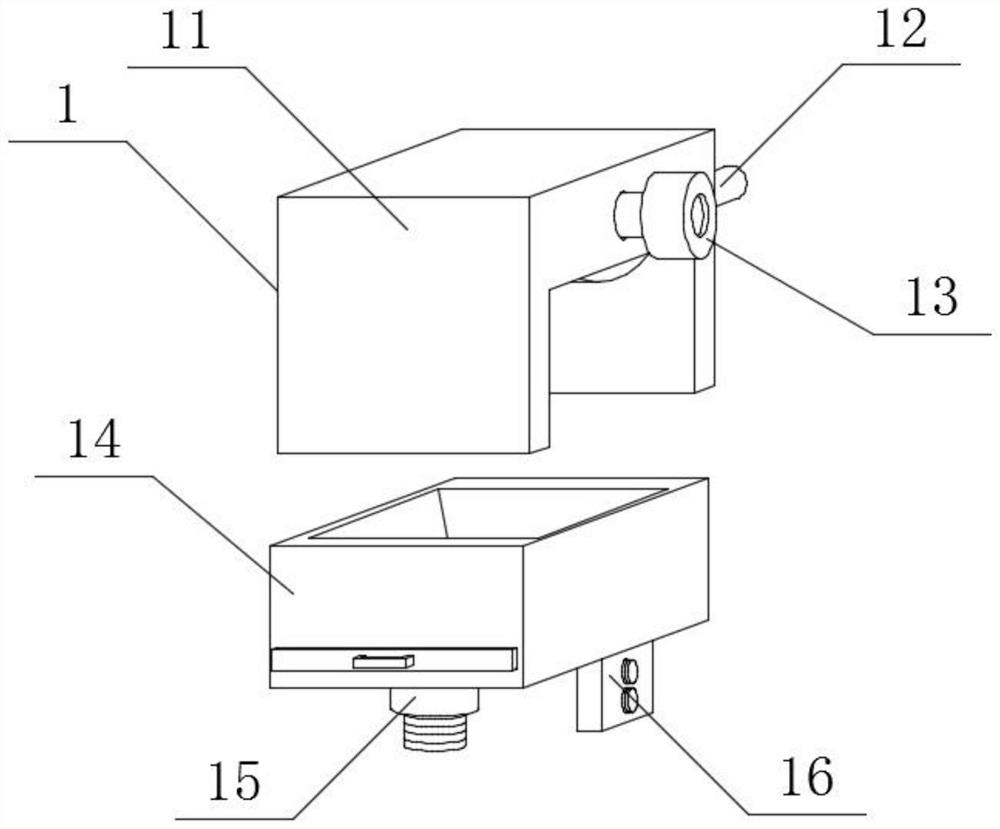

[0033] Such as Figure 1-4 As shown, a rebar grinding device with cooling water recovery function includes a fixed workbench 10 and a motor 9. The front end of the fixed workbench 10 is connected to the right side of the front end face with a motor 9 through a screw, and the rear end face of the motor 9 is plugged into the Connected to the front end of the reducer 8, the right end of the reducer 8 is plugged into the inner side of the left end of the transmission box 7, and the upper position of the inner surface of the transmission box 7 is connected with a transmission rod 6 through a screw. The right side of the outer surface is sleeved with a rotating wheel 4, the rear of the rotating wheel 4 is provided with a control box 5 at the position on the right side of the top end face of the fixed workbench 10, and the left side of the control box 5 is provided with a guide wheel 3, and the guide wheel 3 The left side of the polishing machine 2 is provided with a polishing machin...

Embodiment 3

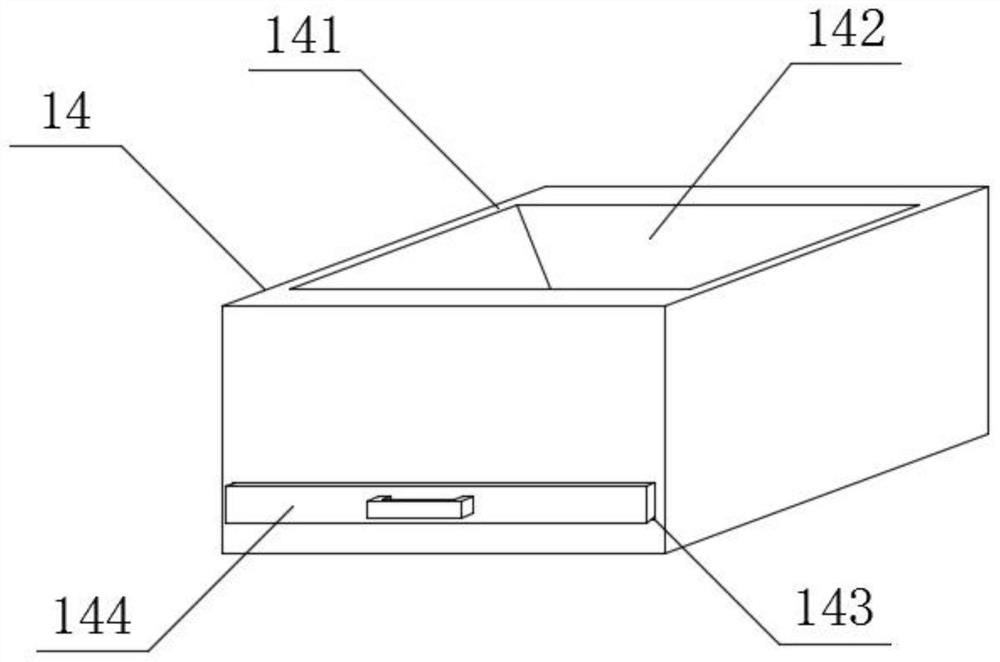

[0036] Such as Figure 1-5 As shown, a rebar grinding device with cooling water recovery function includes a fixed workbench 10 and a motor 9. The front end of the fixed workbench 10 is connected to the right side of the front end face with a motor 9 through a screw, and the rear end face of the motor 9 is plugged into the Connected to the front end of the reducer 8, the right end of the reducer 8 is plugged into the inner side of the left end of the transmission box 7, and the upper position of the inner surface of the transmission box 7 is connected with a transmission rod 6 through a screw. The right side of the outer surface is sleeved with a rotating wheel 4, the rear of the rotating wheel 4 is provided with a control box 5 at the position on the right side of the top end face of the fixed workbench 10, and the left side of the control box 5 is provided with a guide wheel 3, and the guide wheel 3 The left side of the polishing machine 2 is provided with a polishing machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com