Equipment capable of automatically assembling sealing rings

A technology of automatic assembly and sealing ring, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of high labor cost and time-consuming artificial sleeve sealing ring, and achieve a high degree of automation, short time-consuming and production. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with specific embodiments shown in the accompanying drawings. However, these embodiments do not limit the present invention, and the structural, method, or functional changes made by those skilled in the art according to these embodiments are all included in the protection scope of the present invention

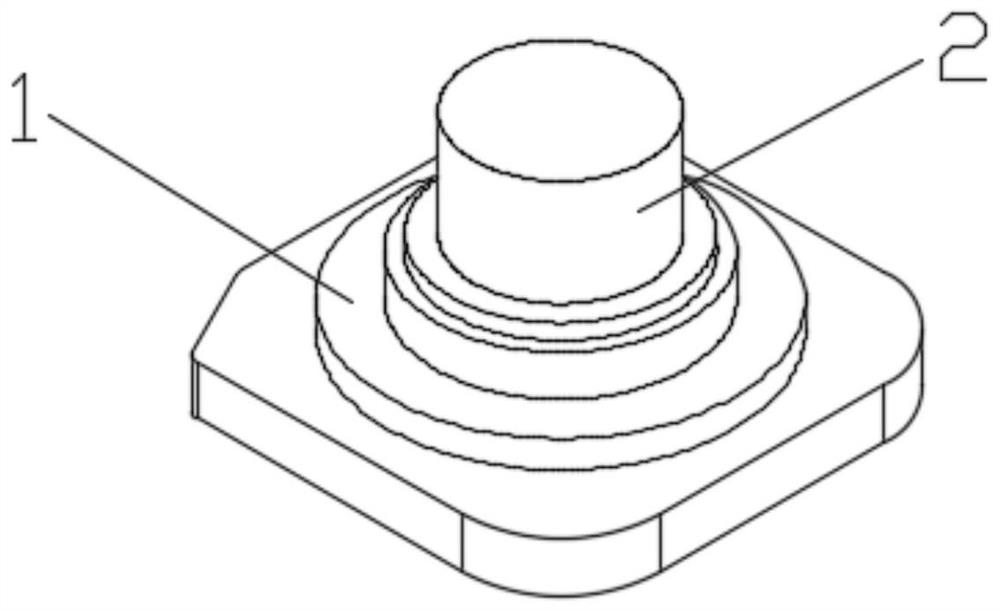

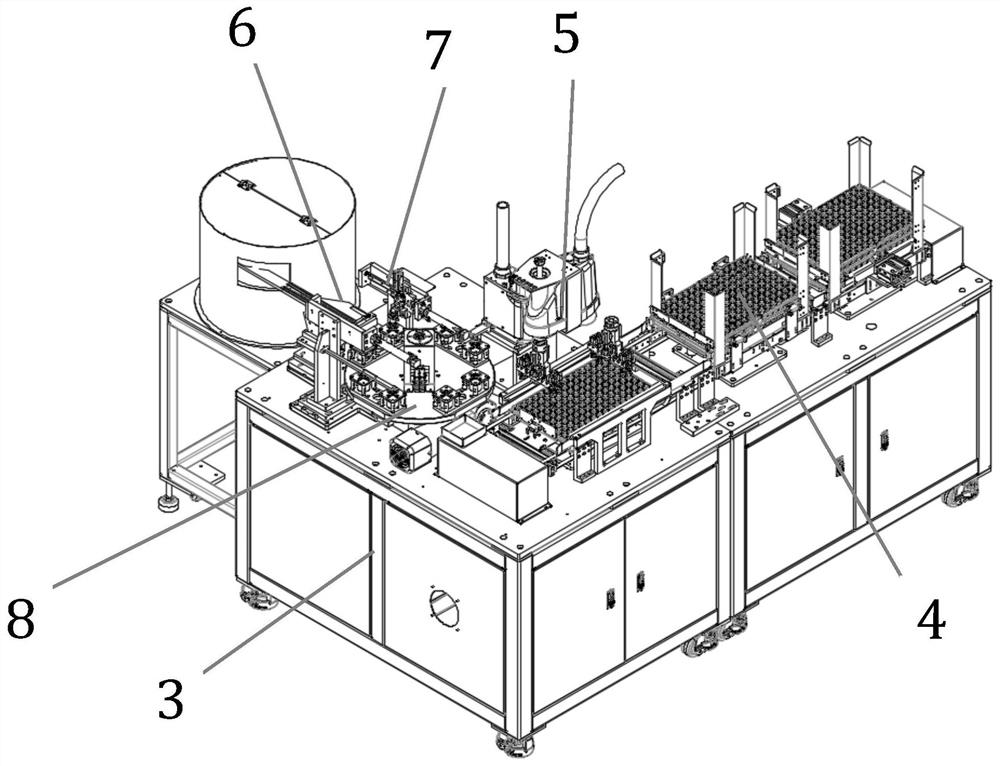

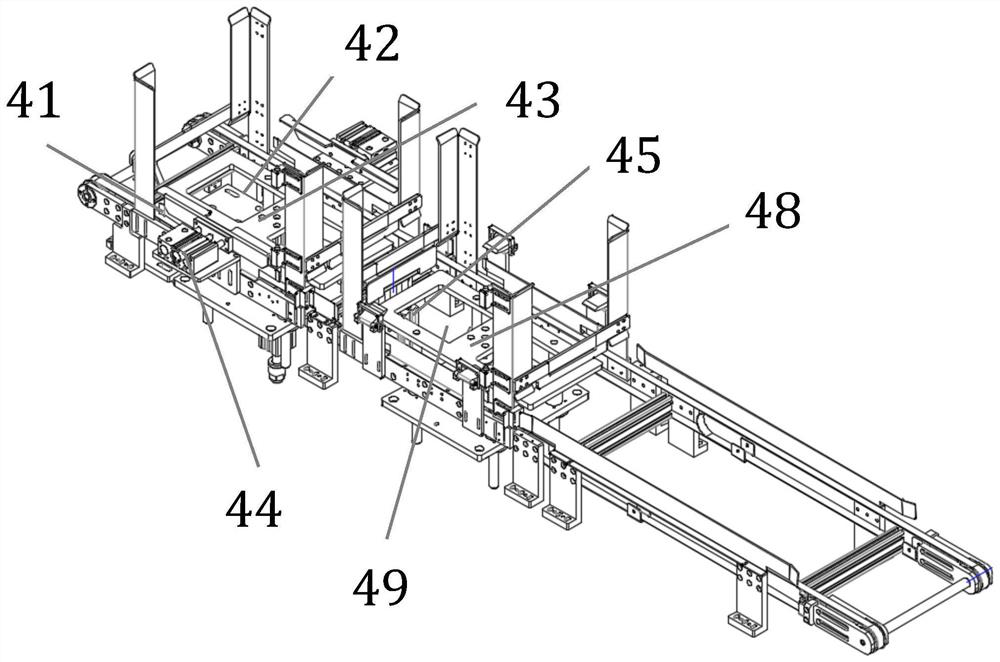

[0030] See Figure 1 to Figure 10 As shown, an automatic sealing ring assembly equipment includes a frame 3, on which a pole feeding module 4, a manipulator picking and placing pole module 5, a sealing ring feeding module 6, and a two-axis suction Seal ring feeding module 7, turntable assembly module 8;

[0031] The assembly module 8 includes a load pole jig 81 , a gear divider 83 , and a stepping motor 84 . The four bearing pole jigs are evenly distributed on the disc, and the drive shaft of the motor drives the input shaft of the gear divider, so that the disc rotates. The pole carrying jig 81 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com