Manufacturing method of aluminum alloy casting and automobile anti-collision beam applying aluminum alloy casting

A technology of aluminum alloy castings and manufacturing methods, which is applied to bumpers and other directions, can solve problems such as difficulty in fully utilizing foamed aluminum energy absorption, shock absorption, unstable product quality, and cumbersome procedures, so as to improve product qualification rate and production efficiency, The effect of reducing emissions and streamlining processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

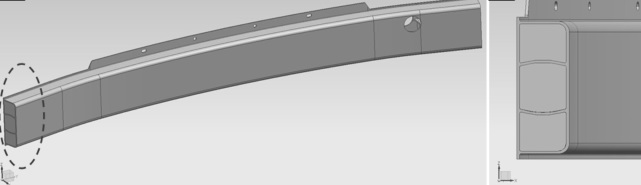

[0031] The main body of the front anti-collision beam of a certain car: the casting dimensions are 1120×125×120mm, the alloy used is A356, the weight is 3.36kg, and the basic wall thickness is 4mm. figure 1 As shown on the left, the dotted box in the figure is a partial enlarged view, namely figure 1 On the right side; the silver-gray area is the built-in shaped aluminum foam, the base is pure aluminum, the weight is 0.58kg, and the equivalent volume density is 0.3-0.5g / cm 3 , The anti-collision beam forming process is low-pressure casting.

[0032] The specific steps are:

[0033] (1) Preparation and treatment of special-shaped closed-cell aluminum foam:

[0034] (a) Preparation process: thickening and stirring of aluminum melt → adding foaming agent and stirring → injecting the foam into the foam investment mold → heat preservation and foaming → cooling of the foam → special-shaped closed-cell aluminum foam, in which the viscosity enhancer and foam They are Ca and TiH2 re...

Embodiment 2

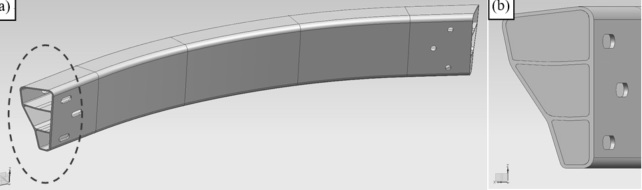

[0042] The main body of the front anti-collision beam of a certain car: the casting dimensions are 1140×145×170mm, the alloy used is Castasil-37, the weight is 5.12kg, and the basic wall thickness is 6mm. figure 2 As shown on the left, the dotted box in the figure is a partial enlarged view, namely figure 2 On the right side; the internal area is the built-in aluminum foam special-shaped parts, the base is pure aluminum, the weight is 0.86kg, and the equivalent volume density is 0.3-0.5g / cm 3 , The anti-collision beam forming process is low-pressure casting.

[0043] The specific steps are:

[0044] (1) Preparation and treatment of special-shaped closed-cell aluminum foam:

[0045] (a) Preparation process: thickening and stirring of aluminum melt → adding foaming agent and stirring → injecting the foam into the foam investment mold → heat preservation and foaming → cooling of the foam → special-shaped closed-cell aluminum foam, in which the viscosity enhancer and foam The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com