Printing material container, and board mounted on printing material container

A technology for printing materials and containers, which is applied in the application of electrical recording technology of charge graphics, equipment and printing of electrical recording technology of application of charge graphics, to achieve the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Embodiments of the present invention will be described below with reference to the drawings.

[0049] A. Example

[0050] Arrangement of the printing device and ink cartridges

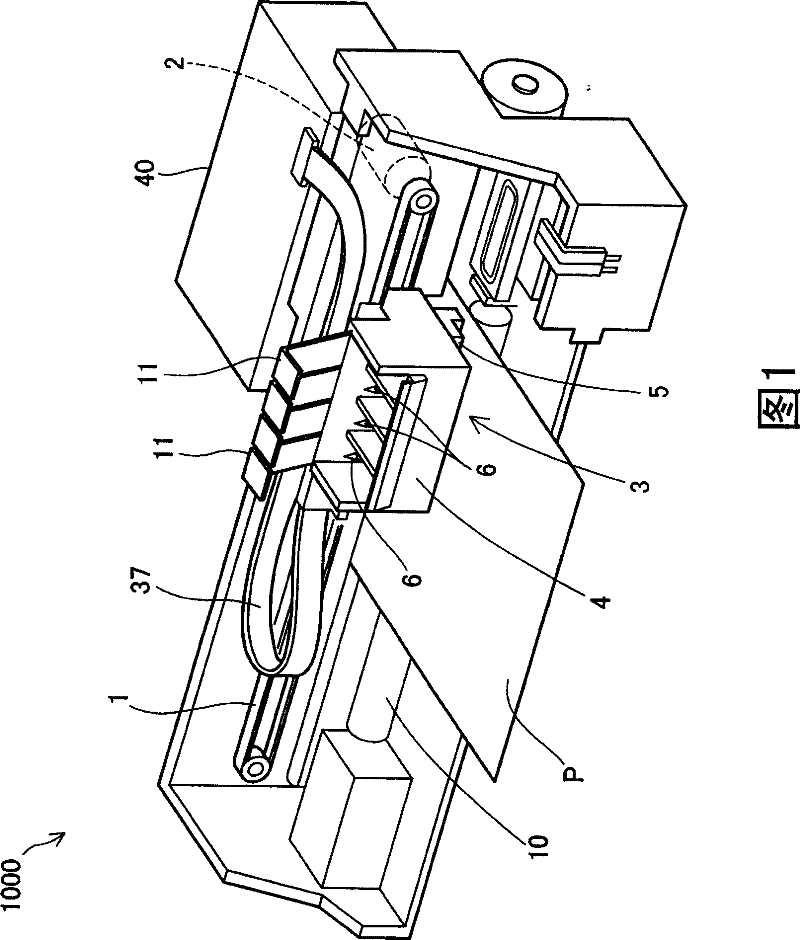

[0051] figure 1 A perspective view showing the configuration of a printing apparatus related to an embodiment of the present invention. The printing apparatus 1000 has a sub scanning feeding mechanism, a main scanning feeding mechanism, and a head driving mechanism. The sub-scanning feed mechanism conveys the printing paper P in the sub-scanning direction using a paper feed roller 10 driven by a paper feed motor (not shown). The main scanning feed mechanism uses the power of the cassette motor 2 to reciprocate the cassette 3 attached to the drive belt in the main scanning direction. The head drive mechanism drives the print head 5 mounted on the cartridge 3 to eject ink and form ink dots. The printing apparatus 1000 additionally includes a main control circuit 40 for controlling the various...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com