Melting device convenient for semiconductor graphite wafer processing and use method thereof

A melting device, semiconductor technology, applied in chemical instruments and methods, mixing methods, mixers with rotary stirring devices, etc. The problem is to solve the poor mixing effect, improve the quality after crushing, and improve the quality of crushing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

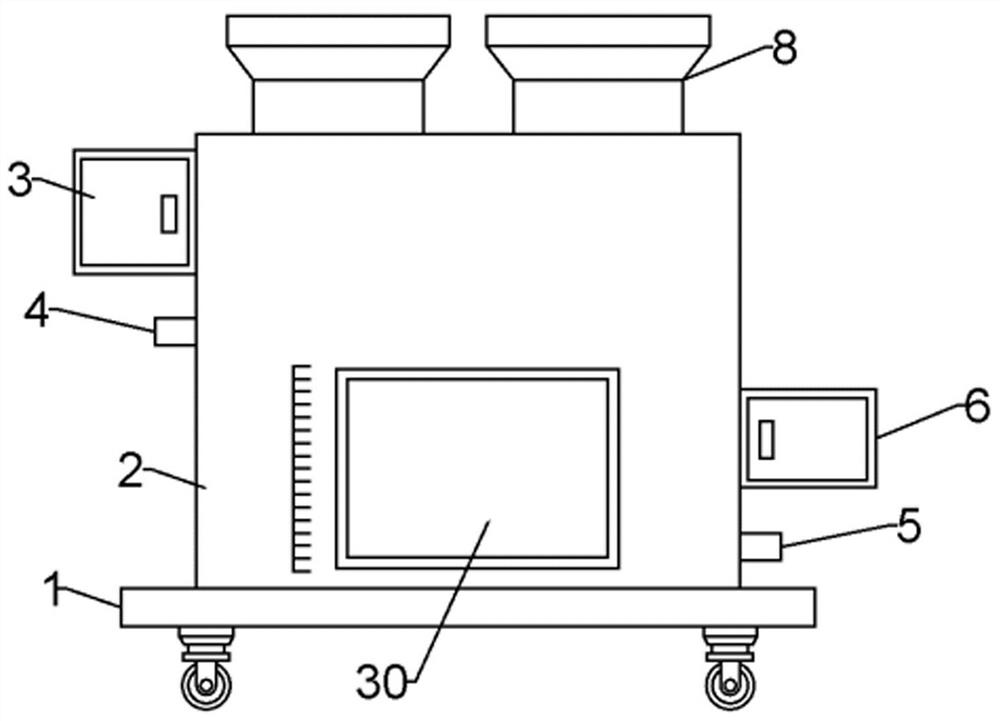

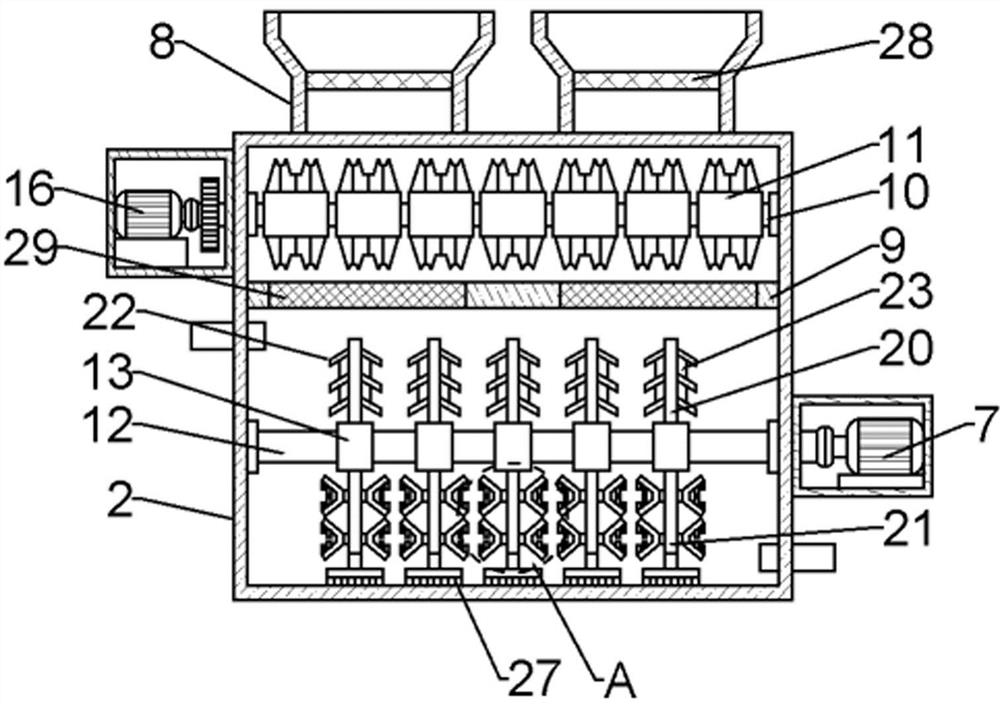

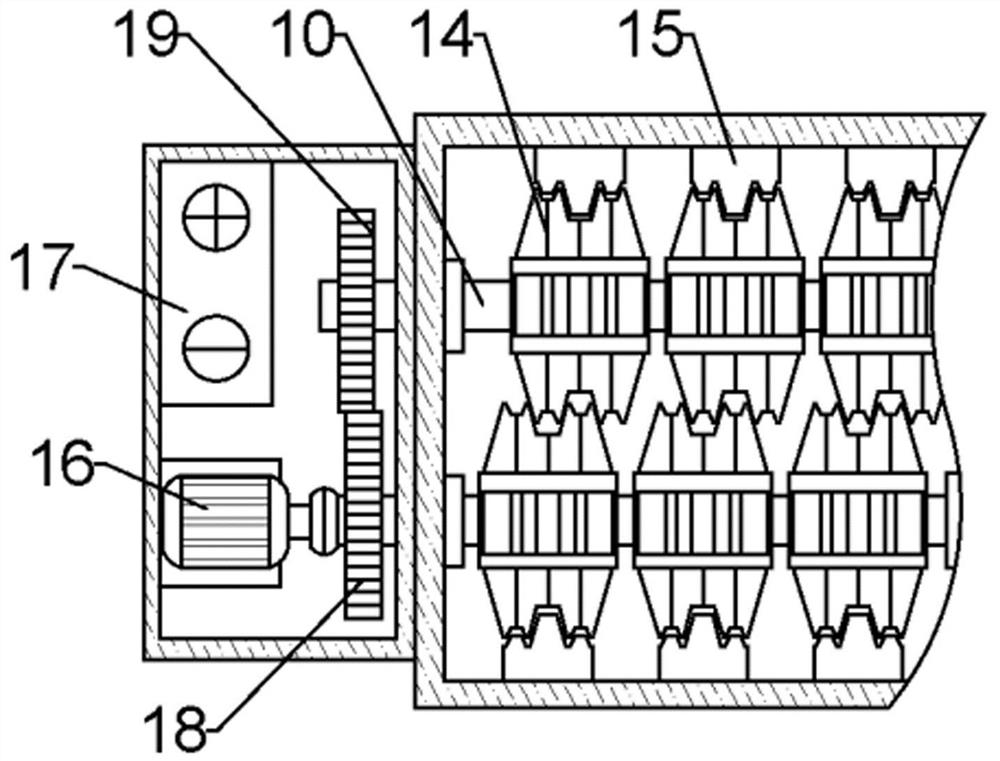

[0030] Embodiment 1: see Figure 1-5 , is convenient to the melting device of semiconductor graphite wafer processing, comprises base 1, and described base 1 is the rectangular plate shape that horizontally arranges, and is fixedly provided with rectangular dissolution box 2 in the middle of the top surface of described base 1, and in described dissolution box A rectangular equipment box 3 is fixed on the top of one side of the 2, and a drive assembly is fixed in the equipment box 3; a liquid inlet pipe 4 is fixed horizontally in the middle of one side of the dissolution box 2; The bottom of the other side of the box 2 is horizontally fixed with a liquid outlet pipe 5, and a rectangular motor box 6 is fixed on the other side of the dissolution box 2 above the liquid outlet pipe 5. In the motor box 6 The first motor 7 is fixed horizontally, and the model of the second motor 7 is YCTL180-4A. Both sides of the middle part of the top surface of the dissolution tank 2 are verticall...

Embodiment 2

[0034] Example 2: see Image 6 , in the present embodiment, the present invention also proposes the use method of the melting device that is convenient to semiconductor graphite wafer processing, comprises the following steps:

[0035] Step 1: Firstly, the first motor 7 and the second motor 16 are electrically connected to the storage battery 17 respectively through wires, and the decomposition liquid is injected into the dissolution tank 2 through the liquid inlet pipe 4, and then the bulk graphite wafer to be melted is passed through the Feed hopper 8 is placed in the dissolution box 2;

[0036] Step 2: Drive the crushing shaft 10 at the front end to rotate by controlling the second motor 16, drive the driving gear 18 to rotate through the rotation of the crushing shaft 10 at the front end, and drive the crushing at the rear end of the crushing chamber through the meshing transmission between the driving gear 18 and the driven gear 19 The shaft 10 rotates, and the crushing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com