LED chip packaging process

A technology of LED chips and packaging technology, which is applied in the direction of electrical components, electrical solid devices, circuits, etc., and can solve problems such as yellow edges, weak light efficiency, and phosphor powder settling to the bottom of the four sides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The scheme of this application is further described in conjunction with the accompanying drawings as follows:

[0024] A packaging process for LED chips, comprising the following steps:

[0025] S1, see figure 1 As shown in figure (a), a carrier 1 and a matrix array of LED chips 2 arranged on the carrier 1 are provided, and there are gaps 3 between adjacent LED chips 2 .

[0026] S2, see figure 1 As shown in the figure (b), the gap 3 is filled with the anti-sedimentation fluorescent glue 4, and the thickness of the anti-settling fluorescent glue 4 is controlled to be flush with the top surface of the LED chip 2, and the anti-settling fluorescent glue 4 is dried and cured. Glue 4. Specifically, do the following:

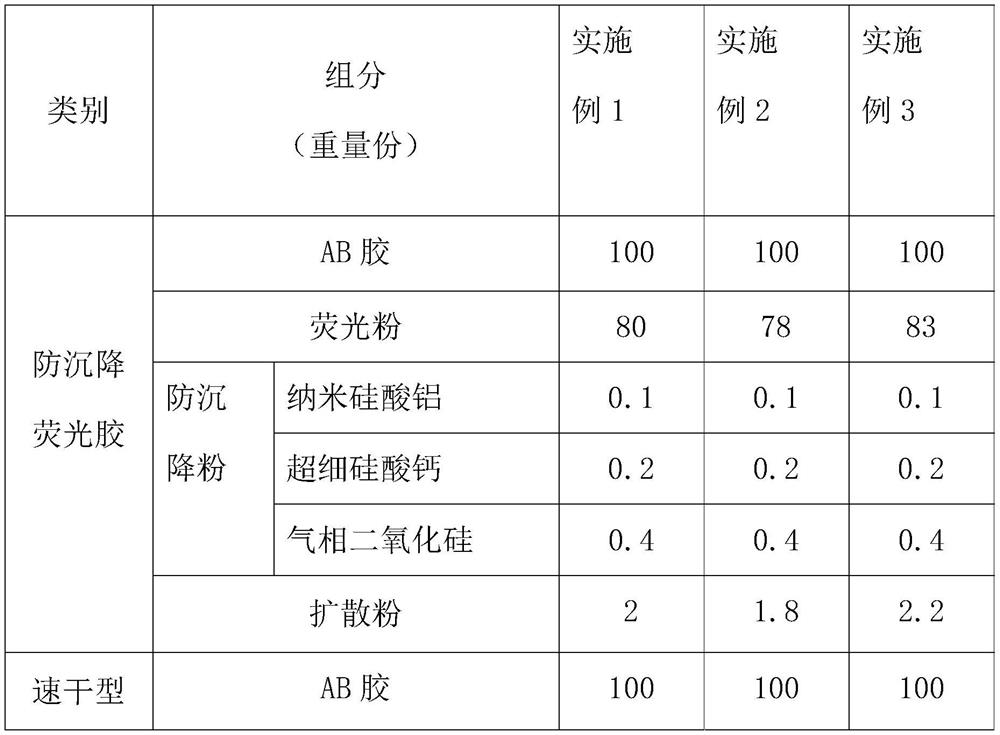

[0027] S2.1. Coating the anti-sedimentation fluorescent glue 4 on the matrix array of LED chips 2, the anti-sedimentation fluorescent glue 4 consists of 85-115 parts by weight of AB glue, 76-83 parts by weight of phosphor powder, 0.3- It is prepared by mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com