Preparation method of GMR magnetic field sensor

A magnetic field sensor, non-magnetic technology, applied in the field of magnetic field detection, can solve the problems of sensor sensitivity decrease, magnetoresistance change rate decrease, magnetic moment direction reversal, etc., to achieve improved measurement range, low hysteresis, high magnetic resistance value and The effect of sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the above and other objects, features and advantages of the present invention more apparent, the following specifically cites the embodiments of the present invention, together with the accompanying drawings, for a detailed description as follows.

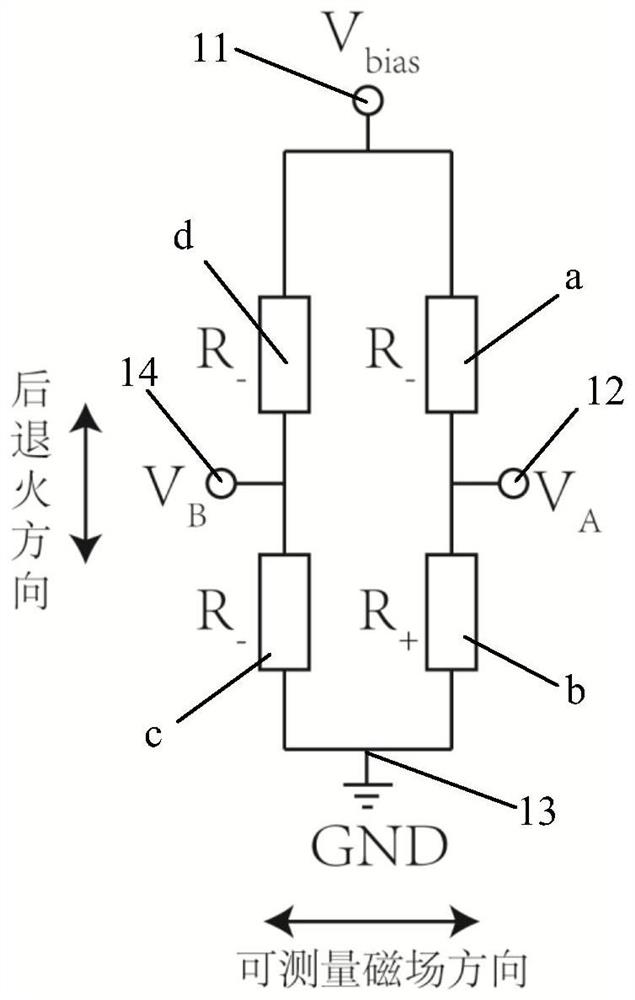

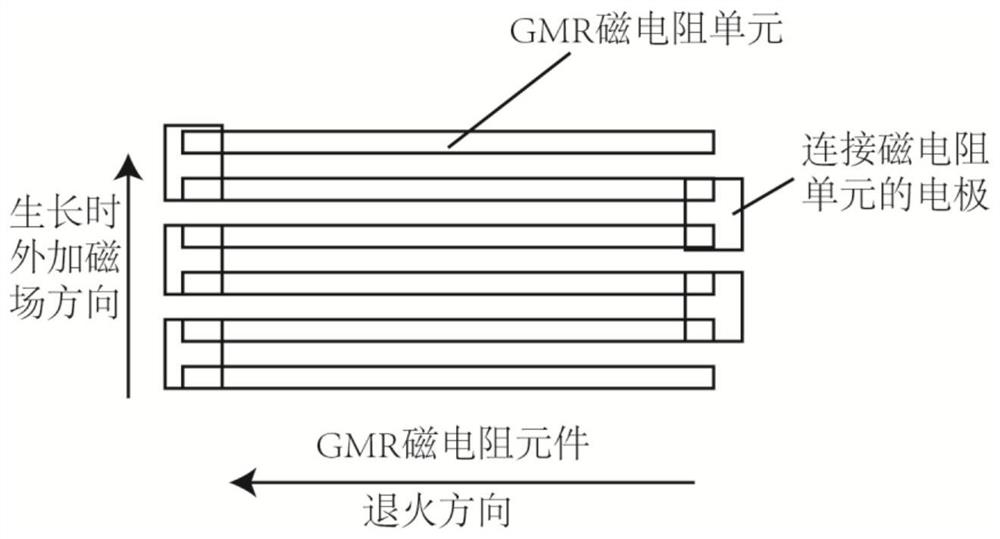

[0031] Such as figure 1 As shown, the full-bridge GMR magnetic field sensor includes 4 bridge-connected GMR magnetoresistive chips (a, b, c, d) with opposite resistance changes. Each GMR magnetoresistive chip can be an independent GMR magnetoresistive unit Or include a plurality of interconnected GMR magneto-resistive units. Each bridge arm in the full-bridge structure is respectively provided with a GMR magnetoresistive chip, and electrodes are arranged between adjacent GMR magnetoresistive chips, that is, there are two pairs of oppositely arranged electrodes (11, 12, 13, 14), One pair is input electrodes (11, 13), and the other pair is output electrodes (12, 14). When a constant voltage V is applied betwe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com