Safety explosion-proof lamp for coal underground construction

An explosion-proof lamp, safety technology, applied in the direction of gas-proof/waterproof device, cooling/heating device of lighting device, lighting and heating equipment, etc., can solve problems such as heat dissipation difficulties, achieve lighting effects, promote rapid flow, and improve heat dissipation speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

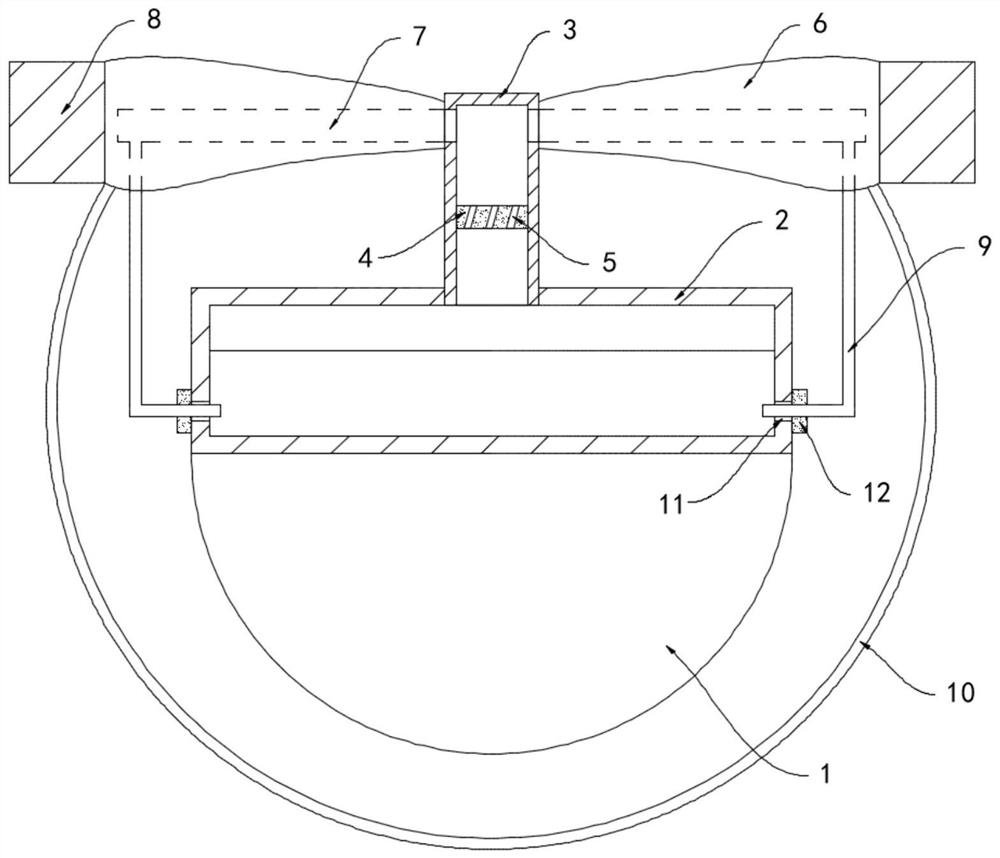

[0018] Such as figure 1 As shown, a safety explosion-proof lamp for underground coal mine construction includes a lamp body 1, the upper end of the lamp body 1 is fixedly connected with a coolant tank 2, the coolant tank 2 is filled with evaporating liquid, and the upper end of the coolant tank 2 is connected with The evaporating tube 3 is fixedly connected to the inner side wall of the evaporating tube 3 with a horizontally arranged turntable 4, and the turntable 4 is provided with a plurality of exhaust holes 5 through which it is arranged. It should be noted that the axial direction of the exhaust hole 5 and the horizontal plane The included angle is 30°, when the gaseous evaporating liquid passes through the vent hole 5, the impact force of the airflow will give a horizontal component force to the side wall of the vent hole 5, and the inclination directions of multiple vent holes 5 are the same, and the component force is formed to drive The torsional force of the turntabl...

Embodiment 2

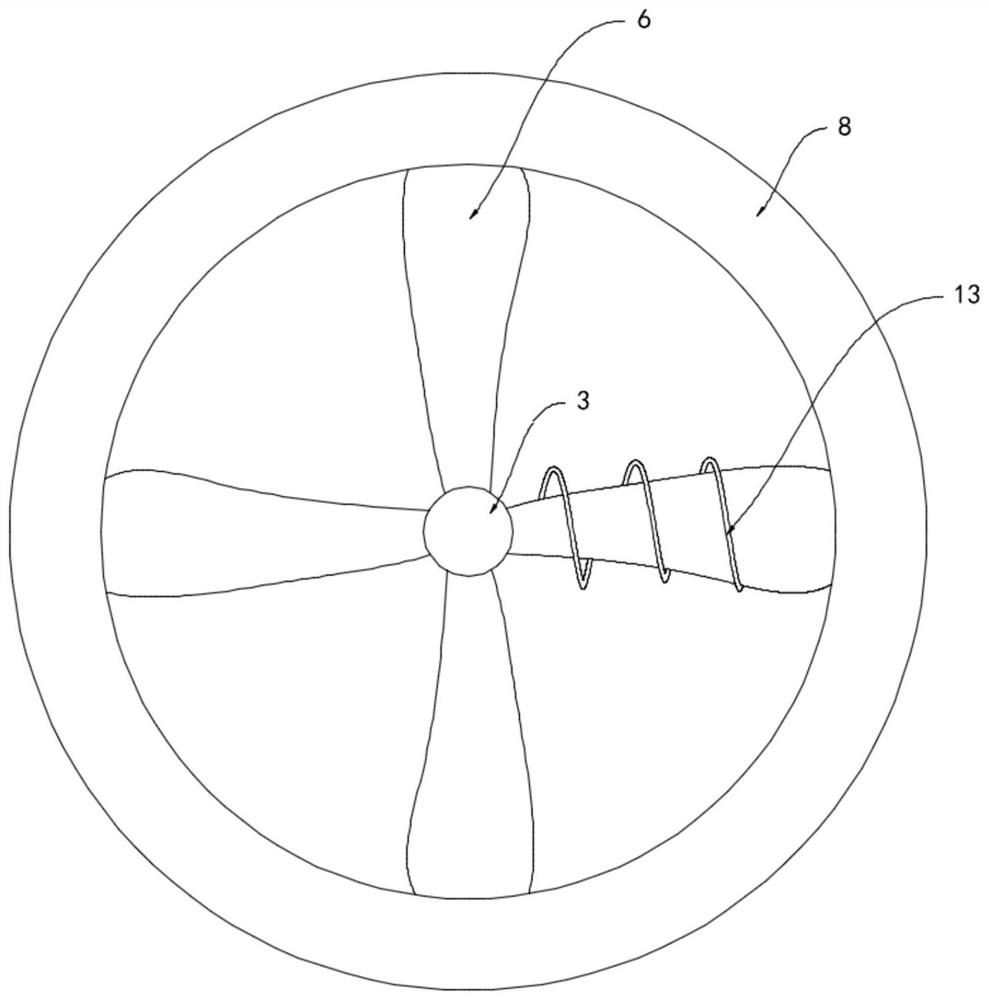

[0023] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the fixed ring 8 is composed of semi-annular magnets with opposite magnetic poles at both ends, and a closed coil 13 is wound around one fan blade 6, and the winding direction of the closed coil 13 is It is perpendicular to the direction of the magnetic field lines of the fixed ring 8 .

[0024] In this embodiment, when the fan blade 6 drives the closed coil 13 to rotate, the closed coil 13 continuously cuts the magnetic field lines of the fixed ring 8, and an induced current is generated in the closed coil 13. According to the principle of electrostatic adsorption, the dust in the air will be absorbed It is adsorbed on the surface of the closed coil 13 to prevent dust from adhering to the surface of the lamp body 1 and the protective net 10 with the airflow, and to avoid affecting its lighting effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com