A six-degree-of-freedom magnetic levitation vibration isolation platform

A technology of vibration isolation platform and degree of freedom, applied in the direction of shock absorber, vibration suppression adjustment, non-rotational vibration suppression, etc., can solve the problems of low integration, large space occupation, complex structure, etc., and achieve high integration , small footprint, good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

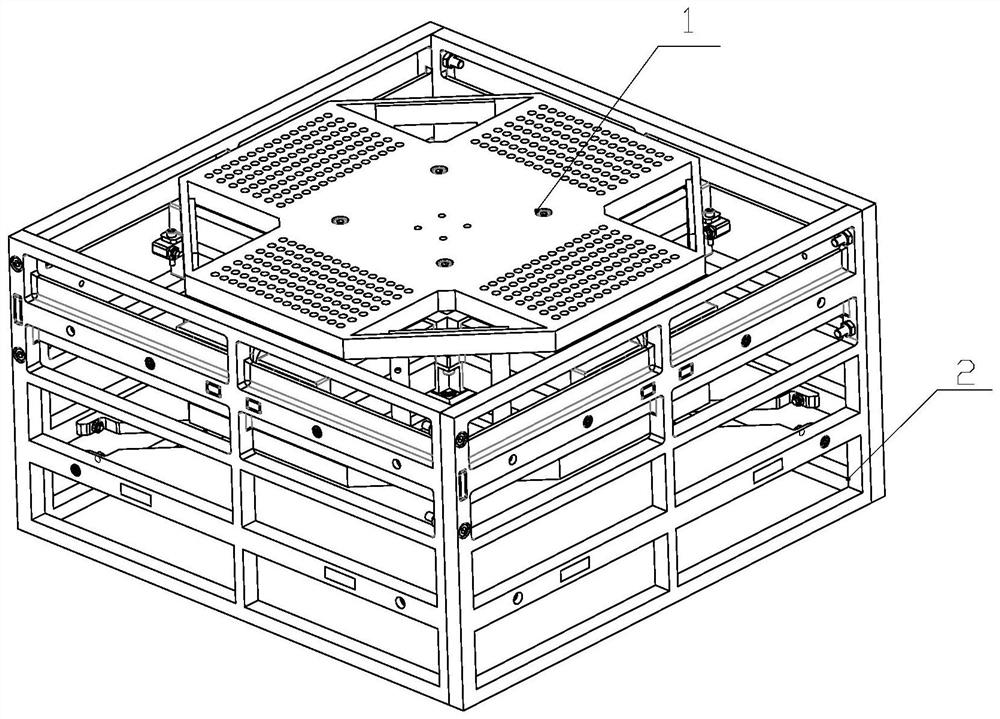

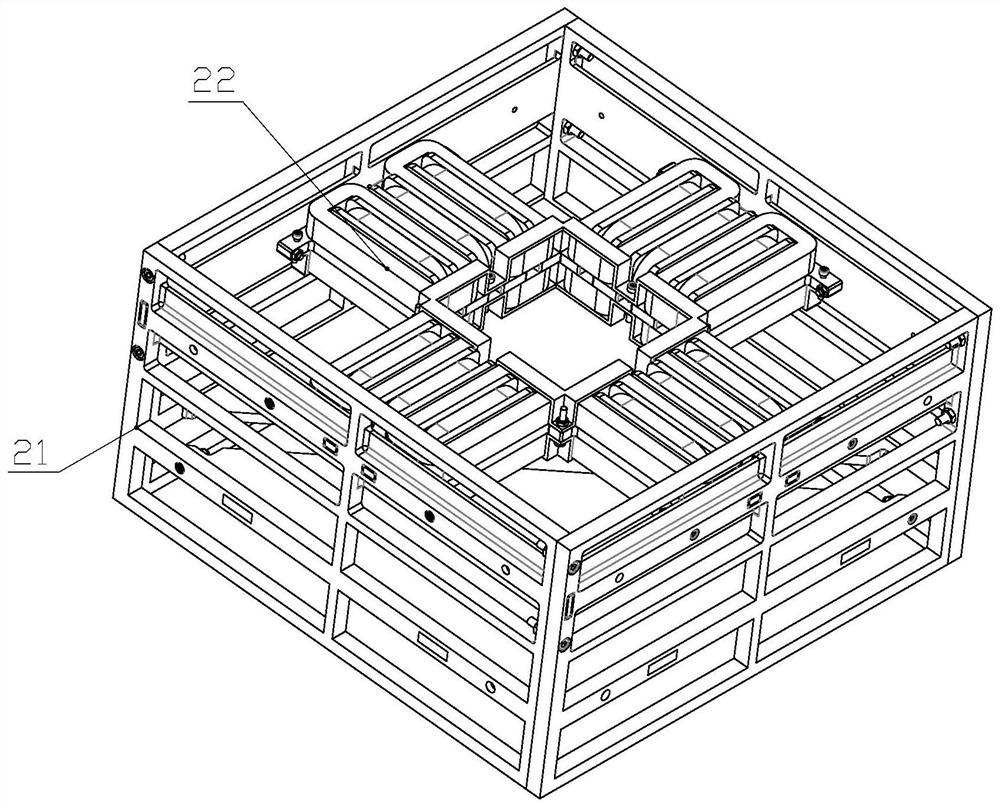

[0026] Embodiment 1: Combining Figure 1~6 Illustrating this embodiment, a spatial six-degree-of-freedom magnetic suspension vibration isolation platform includes a moving platform 1 and a static platform 2, wherein the moving platform 1 includes an upper plate 11, a lower plate 12, a connecting cylinder 13, and four upper permanent magnets Array 14, four lower permanent magnet arrays 15, several PSD displacement sensors 16 and several acceleration sensors 17, the upper plate 11 and the lower plate 12 are arranged in parallel up and down and through the connecting cylinder arranged between the upper plate 11 and the lower plate 12 13 is fixedly connected, four upper permanent magnet arrays 14 are fixedly installed on the bottom surface of the upper plate 11, four lower permanent magnet arrays 15 are fixedly installed on the top surface of the lower plate 12, and several PSD displacement sensors 16 are respectively fixed on the upper surface through the sensor bracket 18 Betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com