Ultra thick seam underground gasification method

A technology for underground gasification and thick coal seams, applied in coal gasification, underground mining, drilling equipment and methods, etc., can solve the problems of high equipment investment, impossibility of penetration, difficulty of penetration, etc., to increase creep volume and increase gas injection wells point, the effect of promoting the creep effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

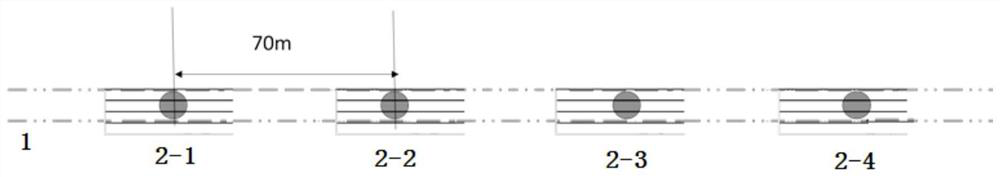

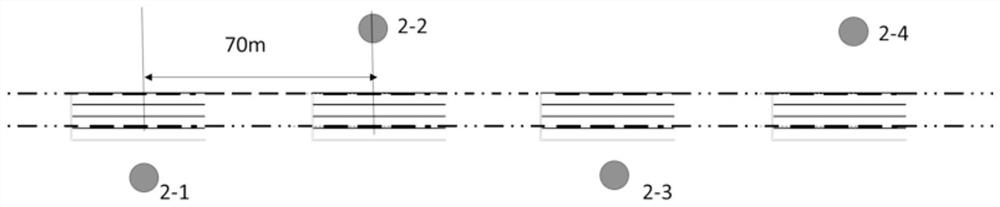

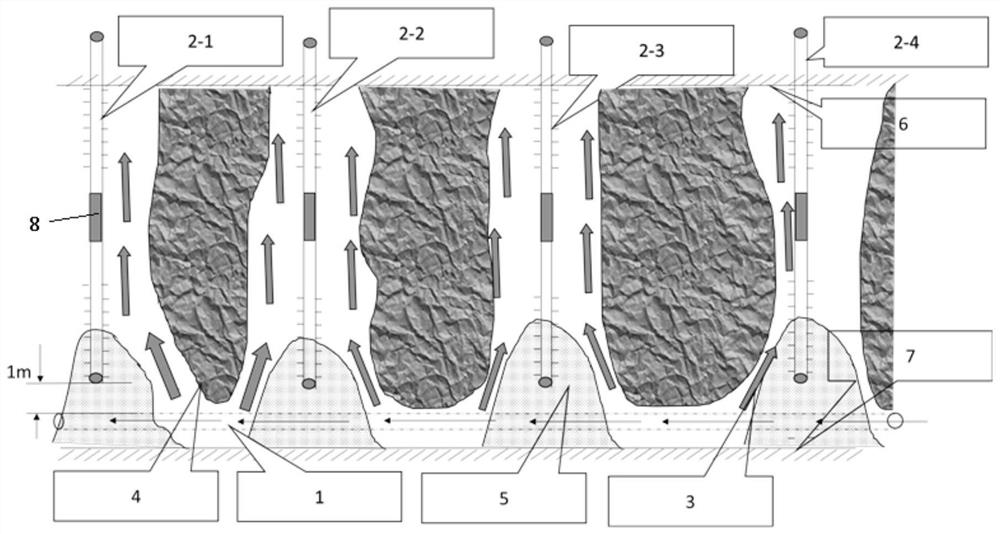

[0042] This embodiment provides the application of the underground gasification method for extremely thick coal seams in target coal seams.

[0043] Description of reservoir properties:

[0044] The burial depth of the simulated reservoir coal seam is 930m, the effective thickness of the reservoir is 60.0m, the distribution of the coal seam is continuous and stable, and it is a high-quality lignite coal seam. There is no pure mudstone interlayer inside the coal seam, and the upper part of the coal seam has a better caprock; the bottom has a mudstone layer, and the permeability of the coal seam is 0.01mD.

[0045] The production process of underground coal seam gasification method is as follows:

[0046] 1) According to the geological characteristics and development status of the reservoir, make a preliminary evaluation:

[0047] The coal seam meets the following conditions: the depth of the reservoir is 930m, the thickness of the coal seam is 60.0m, and the cap rock on the t...

Embodiment 2

[0062] The burial depth of the simulated reservoir coal seam is 1200m, the effective thickness of the reservoir is 40.0m, the distribution of the coal seam is continuous and stable, and it is a high-quality coal seam. The coal seam is relatively clean, there is no pure mudstone interlayer, and the upper part of the coal seam has a good caprock; the water content is less, only about 5%. There is a mudstone layer at the bottom, and the permeability of the coal seam is 0.01-0.03mD.

[0063] The production process of underground coal seam gasification method is as follows:

[0064] 1) According to the geological characteristics and development status of the reservoir, make a preliminary evaluation:

[0065] The coal seam meets the following conditions: the depth of the reservoir is 1200m, the thickness of the coal seam is greater than 40.0m, and the cap rock on the top of the reservoir is developed, which can effectively prevent gas escape and water seepage.

[0066] 2) Accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com