Graphite crucible convenient for semiconductor crystal growth, and use method thereof

A technology for graphite crucible and crystal growth, applied in the field of graphite crucible, can solve the problems of high workload and labor intensity of staff, inconvenient clamping and fixing of iridium rod, easy shaking of iridium rod when lifting and rotating, etc., so as to improve the pulling efficiency. , Improve clamping firmness, reduce workload and labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

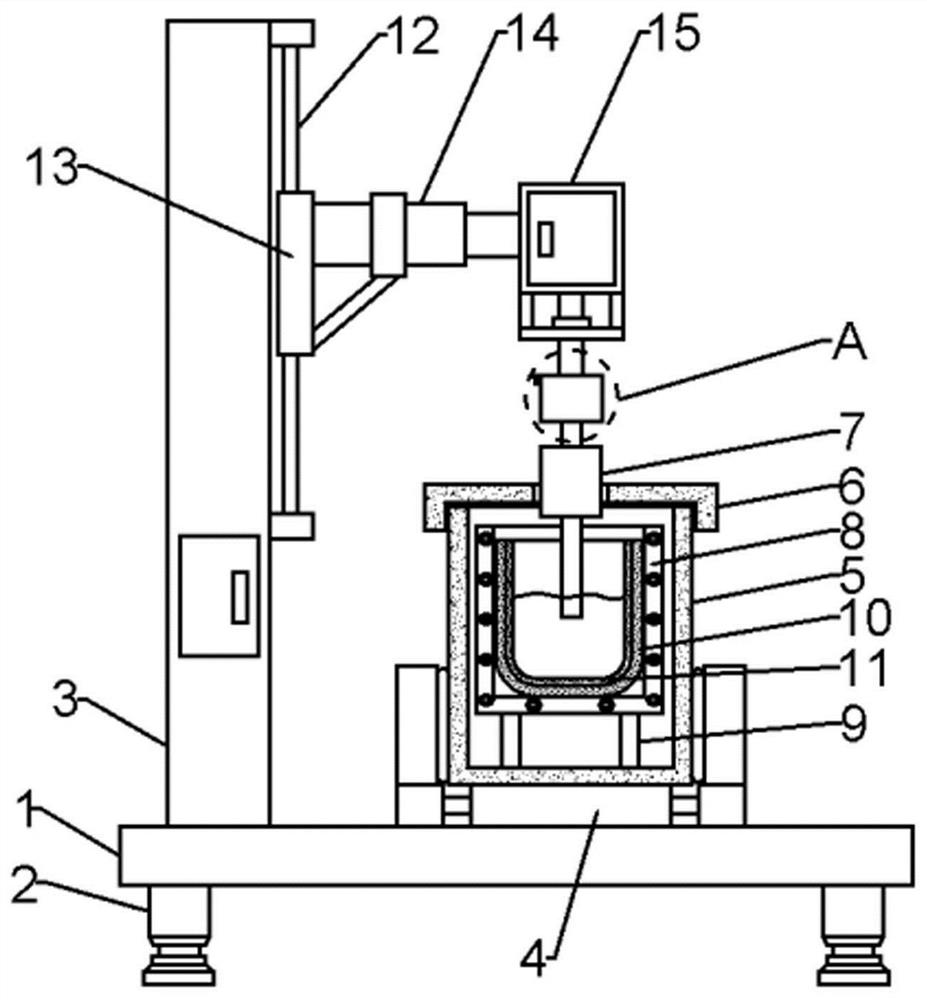

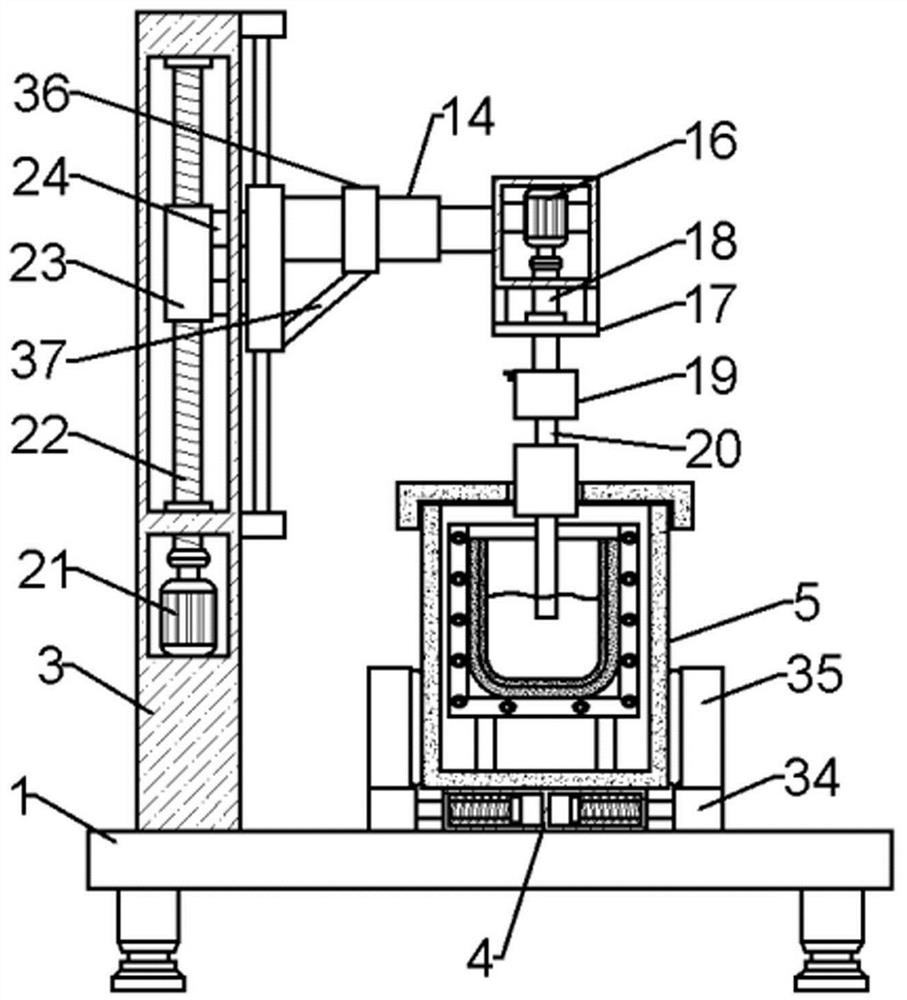

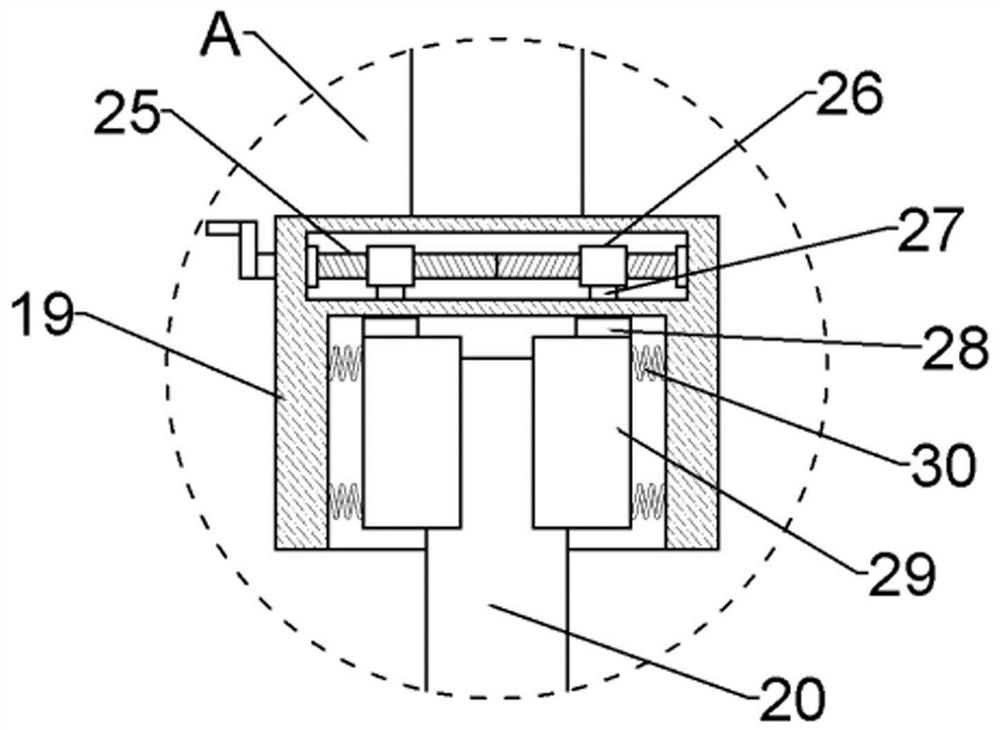

[0031] Example 1: see Figure 1-5 , a graphite crucible for semiconductor crystal growth, comprising a base 1, the base 1 is a horizontally arranged rectangular plate shape, four corners of the bottom surface of the base 1 are vertically fixed with supporting legs 2; The middle part of one side of the top surface is vertically fixed with a rectangular column 3, and the middle part of the top surface of the base 1 is horizontally fixed with a rectangular plate-shaped placement seat 4, and the placement seat 4 is vertically provided with an opening facing upwards. The furnace body 5 is covered with a furnace cover 6 at the top opening of the furnace body 5, and a circular through hole is provided in the middle of the top surface of the furnace cover 6, and a vertically fixed hole is installed in the circular through hole. There is a guide tube 7, and a graphite heat field 8 with an opening facing upwards is vertically provided in the body of furnace 5, and support plates 9 are v...

Embodiment 2

[0036] Example 2: see Figure 6 , in the present embodiment, the present invention also proposes a method for using a graphite crucible for semiconductor crystal growth, comprising the following steps:

[0037] Step 1, first electrically connect the electric push cylinder 14, the first motor 16 and the second motor 21 to an external power supply through wires, and a seed crystal is fixed at the bottom of the iridium rod 20;

[0038] Step 2, drive the moving block 31 at the inner end of the round bar 32 by moving the splint 35 outwards to squeeze the return spring 33, then place the furnace body 5 on the placement seat 4 between the two splints 35, and pass the return spring 33 The elastic force of the rod 32 drives the round rod 32 to shrink inwardly, and the splint 35 on the top of the rectangular bar 34 is driven by the shrinkage of the round rod 32 to limit and clamp the furnace body 5; then, the raw material in the quartz crucible 11 is melted into a liquid state;

[0039...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com