Film coating liquid for halogenated butyl rubber plug, film coated rubber plug, and preparation methods and applications of film coating liquid and film coated rubber plug

A technology of halogenated butyl rubber and film coating liquid, which is applied in the directions of application, sealing with stopper, coating, etc., can solve the problems such as the halogenated butyl rubber stopper cannot meet the packaging requirements, restrict the development of traditional Chinese medicine injection, and increase the cost of medicines, etc. Achieve good sealing performance and peel strength, increase elasticity, and extend the effect of expiration date

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

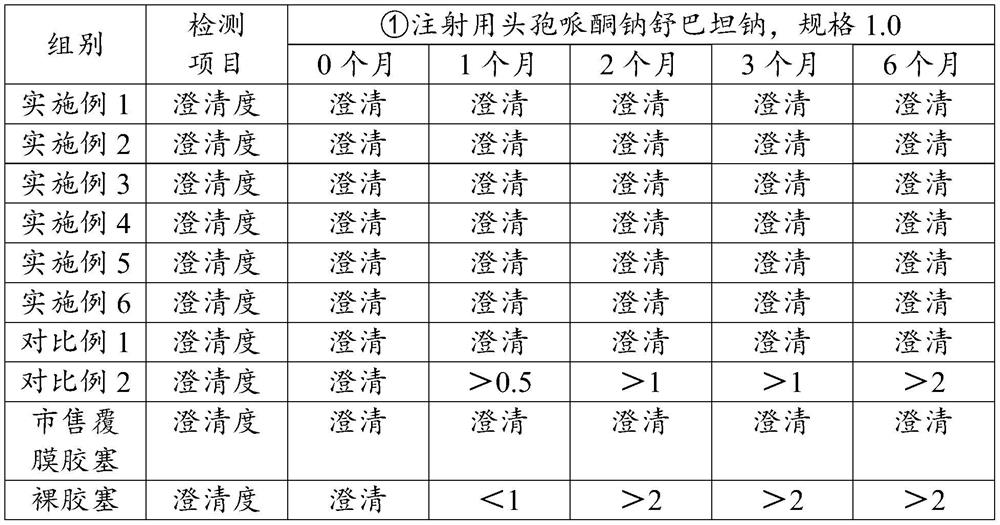

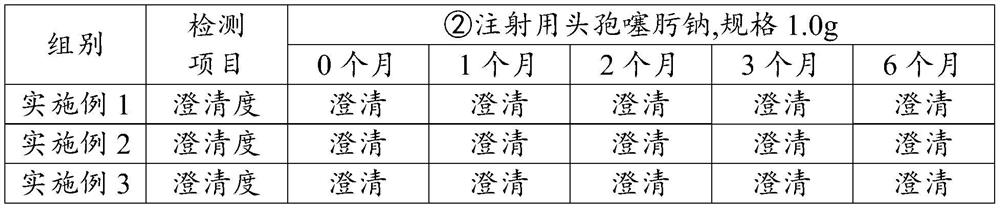

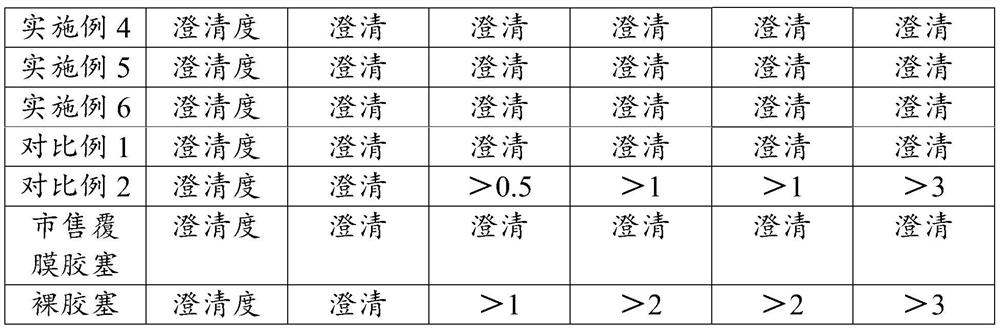

Examples

preparation example Construction

[0044] The preparation method of the coating liquid provided by the invention has simple process, convenient operation, can be completed without expensive reaction equipment, and is suitable for popularization and application.

[0045] Preferably, the auxiliary crosslinking agent includes potassium persulfate; the anticoagulant includes succinic acid and / or potassium nitrate.

[0046] In the present invention, the meaning of "and / or" means that succinic acid can be selected as the anticoagulant alone, potassium nitrate can also be selected as the anticoagulant alone, and succinic acid and potassium nitrate can also be selected as the anticoagulant at the same time.

[0047] Optionally, the added amount of the potassium persulfate is 0.3% of the weight of the solvent; the added amount of the succinic acid is 0.2% of the weight of the solvent; the added amount of the potassium nitrate is 0.2% of the weight of the solvent.

[0048] Preferably, the pressure during mixing is 0.03-0...

Embodiment 1

[0062] This embodiment provides a coating solution for halogenated butyl rubber stoppers, including:

[0063] 30 parts of aryl siloxane, 100 parts of polytetrafluoroethylene and 300 parts of solvent.

[0064] Its preparation method includes:

[0065] After mixing the formulated amount of aryl siloxane, polytetrafluoroethylene, solvent and potassium persulfate, then adding succinic acid and potassium nitrate to react to obtain the coating solution for halogenated butyl rubber stopper;

[0066] Wherein, the solvent is water;

[0067] The add-on of described potassium persulfate is 0.3% of solvent weight; The add-on of described succinic acid is 0.2% of solvent weight; The add-on of described potassium nitrate is 0.2% of solvent weight;

[0068] The pressure during mixing is 0.05Mpa, the temperature is 75°C, and the time is 2 hours;

[0069] The temperature during the reaction was 100° C., and the time was 8 hours.

Embodiment 2

[0071] This embodiment provides a kind of coating solution for halogenated butyl rubber stopper, and the difference with embodiment 1 is:

[0072] 40 parts of aryl siloxane, 80 parts of polytetrafluoroethylene and 500 parts of solvent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com